BEVEL RIPPING

This operation is the same as ripping except the bevel angle is set to an angle other than zero

degrees.

WARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the guard and splitter for proper alignment and clearance with saw blade.

Check alignment after each change of bevel angle.

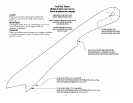

RIPPING SMALL PIECES

It is unsafe to rip small pieces. It is not safe to put your hands close to the blade. Instead, rip a larger

piece to obtain the desired piece. When a small width is to be ripped and the hand cannot be safely

put between the blade and the rip fence, use one or more push sticks. Apattern is included on the

back cover to make push sticks. Use them to hold the workpiece against the table and fence, and

push the workpiece fully past the blade. See Figure 28.

CROSSCUTTING

1. Remove the rip fence and place the miter gauge in the appropriate slot.

2. Adjust the blade height so that the blade is about 1/8" (3.2mm) higher than the top of the

workpiece.

3. Hold the workpiece firmly against the miter gauge with the path of the blade in line with the

desired cut location. Keep the workpiece an inch or so in front of the blade. KEEP BOTH

HANDS AWAY FROM THE BLADE AND THE PATH OF THE BLADE.

4. Start the saw motor and allow the blade to come up to speed.

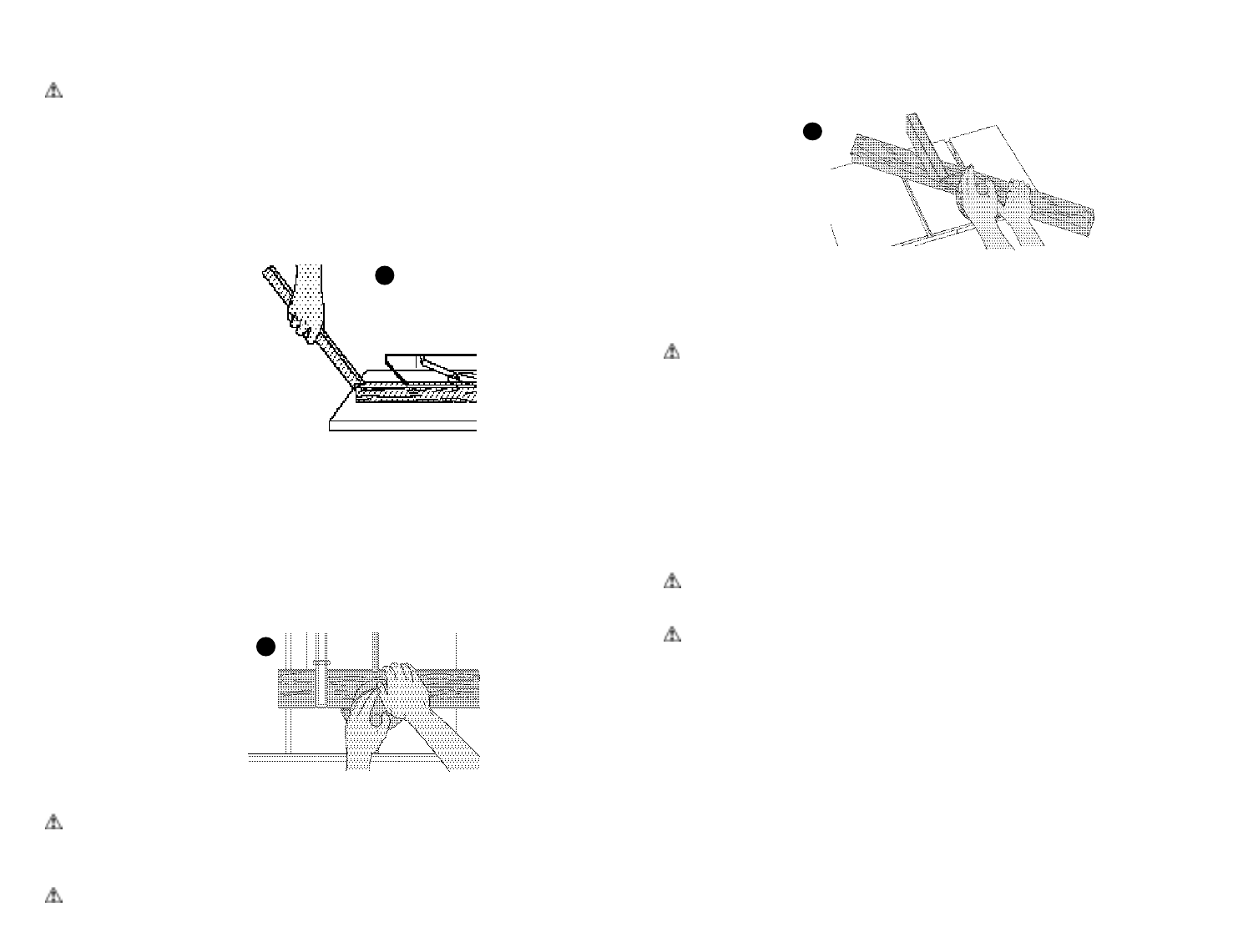

5. While using both hands to keep the workpiece against the face of the miter gauge, and

holding the workpiece flat against the table, slowly push the workpiece through the blade.

See Figure 29.

6. Never try to pull the workpiece with the blade turning. Turn the switch off, allow the blade

to stop, and carefully slide with workpiece out.

CAUTION: Never touch or hold onto the “free” or “cut off” end of the workpiece.

BEVEL CROSSCUTTING

This operation is the same as crosscutting except that the bevel angle is set to an angle other

than 0°.

WARNING: Before connecting the table saw to a power source or operating the saw,

always inspect the guard and splitter for proper alignment and clearance with saw blade.

Check alignment after each change of bevel angle.

12

MITERING

This operation is the same as crosscutting except the miter gauge is locked at an angle other

than 0°. Hold the workpiece FIRMLY against the miter gauge and feed the workpiece slowly

into the blade (to prevent the workpiece from moving). See Figure 30.

COMPOUND MITERING

This is a combination of bevel crosscutting and mitering. It is infrequently used. Follow the

instruction for both bevel crosscutting and mitering.

DADO CUTTING

CAUTION: Do not attempt to stack dado blades thicker than 13/16" (20.6mm). For any

dado stack greater than 1/2” (12.7mm), remove the outer washer and do not use. Place the

dado stack on the spindle and tighten the arbor nut with the blade wrench. Do not use dado

blades larger than 8" (203mm) diameter.

NOTE: Dado cuts require a special dado insert catalog number BT510 sold separately.

Since Dado cuts are not through cuts, the cuts must be performed with the blade guard

removed. To remove the guard/spreader assembly, loosen the two nuts (A) in Figure 22 and

remove the guard assembly.

Anytime a cut is required that is considerably wider than the saw kerf, a dado is used. A dado

cut is commonly used to add support and line up a shelf for a cabinet, bookcase or some such

project. When using the dado, the guard must be removed. Use EXTREME care when using

the dado without the guard. If a deep cut is required . . .use several successive passes rather

than attempting to make it with one pass. Maximum dado width on this saw is 13/16" (20.6mm).

DO NOT USE WIDER COMBINATIONS.

CAUTION: Always check dado blade clearance before plugging in the saw.

Be sure to place the guard back in position and check adjustments when the dado cuts are

complete.

WARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the guard and splitter for proper alignment and clearance with saw blade. Check

alignment after each change of bevel angle.

DUST COLLECTION

Your table saw is equipped with a dust shroud with a 2-1/2” (63.5mm) dust collection port. For

best results, connect a vacuum to the port at the rear of the saw.

If the saw is operated without a vacuum attached, most of the dust will be blown out the dust

collection port. After extended use, the saw’s dust collection system may become clogged. To

clear the dust collection system:

a) Unplug the saw.

b) Use a paint stick or long screwdriver to loosen debris and cut-offs and pass it out through

the port.

When cutting wet wood without a vacuum, making long narrow cut-offs or when cutting with

a dado blade, clean the dust collection port each time.

29

28

30