16

Turn crankshaft to be sure there is no binding between

bearing surfaces and journals. Replace oil screen, bottom cover

plate, valve plates and cylinder heads.

Motor Removal

MOTOR END BELL — Remove motor end bell carefully to

prevent damage to the stator. Use three

7

/

16

- 14- x 5-in. studs

for guides and support. Inspect suction strainer in end bell.

Clean it with solvent or replace if broken or corroded.

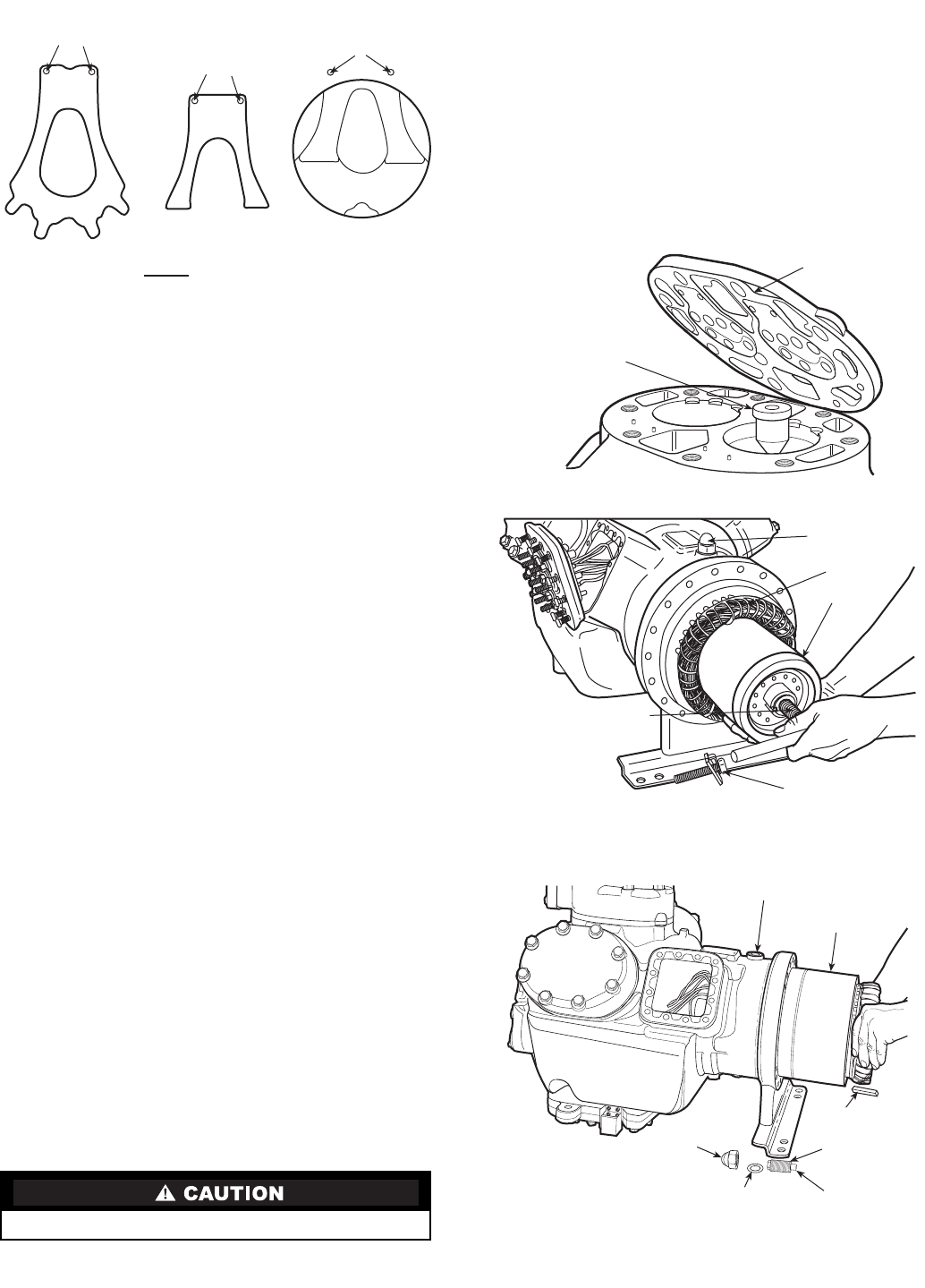

REMOVE ROTOR — Bend rotor lock washer tab backward

and remove rotor lock bolt. If crankshaft turns, preventing lock

bolt from being loosened, remove a cylinder head and valve

plate and place a rubber plug (06R suction plug) on top of one

piston (Fig. 20). Replace valve plate assembly and cylinder

head (only 2 bolts required to hold cylinder head in place). Pro-

ceed to remove rotor lock bolt, lock washer and plate washer.

Use a jackscrew to remove rotor (Fig. 20). Insert a brass

plug into rotor hole to protect end of crankshaft from jack-

screw. Support rotor while it is being removed to prevent stator

damage. Remove ring spacer between rotor and crankshaft

(if used).

Clean rotor thoroughly with solvent. If stator is to be

replaced, a matching rotor must be used.

REMOVE STATOR (Fig. 21) — Stator is a slip fit in motor

housing. It is held in place by both an axial key and a locking

assembly consisting of an acorn nut, locking pin, motor lock

bushing and a washer (see Fig. 21). Remove acorn nut and

washer. Back out locking pin and bushing and slide stator out.

Axial key positions stator and crankcase. If necessary, heat

crankcase motor housing (not over 20 to 30 F above stator

temperature).

Check stator for damage to windings and lead wires. Use a

megohmmeter to check for grounds or shorts between

windings.

Motor Replacement

STATOR AND ROTOR — Install stator halfway into hous-

ing. Insert the terminal leads first, guiding them to terminal

plate opening as stator is being inserted.

Replace ring spacer (Fig. 11, item 21) on crankshaft. Ease

rotor onto shaft until it begins to feel snug. Insert rotor key, and

push rotor the remainder of the way on shaft. Replace rotor

lock bolt with lockwasher and plate washer.

Push stator into housing until it lines up correctly with rotor

(Fig. 22).

Line up keyways in stator and crankcase and replace stator

locking assembly, then drive key into keyway and stake over

keyway in stator to secure key. When a new motor is being

installed, the stator must be drilled and a new locking pin and

motor lock bushing used (see Fig. 23 and instructions).

Connect stator leads to proper terminals on terminal plate.

Refasten terminal plate and junction box to compressor.

Replace motor end bell using studs for support. Remove rubber

plug (if used) from piston head. Replace valve plate assembly,

cylinder head, and terminal plate assembly. Torque 12 bolts

holding terminal plate to crankcase at 30 to 40 lb-ft.

Do not push stator in completely until rotor is in place.

DOWEL

HOLES

DOWEL

HOLES

DOWELS IN

CYLINDER DECK

FOR SUCTION

VALVE AND BACKER

SUCTION

VALVE

BACKER

PLACE AGAINST

CYLINDER DECK,

UNDER SUCTION VALVE

TOP VIEW OF PISTON

IN CYLINDER

Fig. 19 — Piston, Suction Valve and

Backer Positions

VALVE PLATE

RUBBER PLUG

STATOR LOCKING

ASSEMBLY

STATOR

ROTOR

ROTOR LOCK BOLT

JACKSCREW

LOCKING PIN BOSS

STATOR

KEY

ACORN

NUT

WASHER

LOCKING PIN

MOTOR LOCK

BUSHING

Fig. 20 — Removing Rotor

Fig. 21 — Removing Stator