9

SERVICE

Protection Devices

HIGH-PRESSURE SWITCH — Check by throttling con-

denser water or blocking airflow on air-cooled units, allowing

head pressure to rise gradually. Check discharge pressure

constantly throughout procedure. Compressor should shut off

within 10 psi of values shown in Table 4.

LOW-PRESSURE SWITCH — Check by slowly closing

suction shutoff valve or by completely closing liquid line

shutoff valve. A decrease of suction pressure will follow.

Compressor should shut off within 4 psi of values shown in

Table 4.

OIL PRESSURE SWITCH (OPS) — The oil pressure switch

protects against damage from loss of oil or loss of oil pressure

during unit start-up. If the oil pressure differential sensed by the

OPS is 6 psig or less on unit start-up, the switch remains closed

and the OPS heater is energized.

The switch time delay is approximately 45 seconds. If after

45 seconds the oil pressure differential sensed by the OPS is

less than 11 psig, the heater remains energized. The OPS

temperature actuated switch then opens and the compressor is

deenergized. If the differential reaches 11 psig, the OPS opens

and deenergizes the heater and the system operates normally.

See Table 4.

To restart the unit, push the OPS reset button and then push

the control circuit switch on the unit control box to OFF and

then to ON.

Table 4 — Factory Switch Settings

NOTES:

1. Values for the high- and low-pressure switches based on R-22.

For other refrigerants, reset to pressure corresponding to satura-

tion temperatures indicated by the listed pressures.

2. Values for oil pressure are above operating suction pressure

(pressure differential between suction and discharge pressures

of oil pump).

TIME GUARD® CONTROL — The Time Guard control

protects against short cycling. See Start Compressor.

CRANKCASE HEATER — The crankcase heater prevents

absorption of liquid refrigerant by oil in crankcase during brief

or extended shutdown periods. Source of 115-volt power is the

auxiliary control power, independent of the main unit power.

This assures compressor protection even when main unit

power disconnect switch is off.

Compressor Thermal Protection —

A discharge

temperature sensor, installed in one cylinder head, detects an

overtemperature condition. If the discharge temperature

exceeds 295 ± 5 F, the sensor contacts open and the compressor

shuts down. The sensor reset temperature is 235 F minimum.

See Fig. 8 for control circuit connections.

Capacity Control System

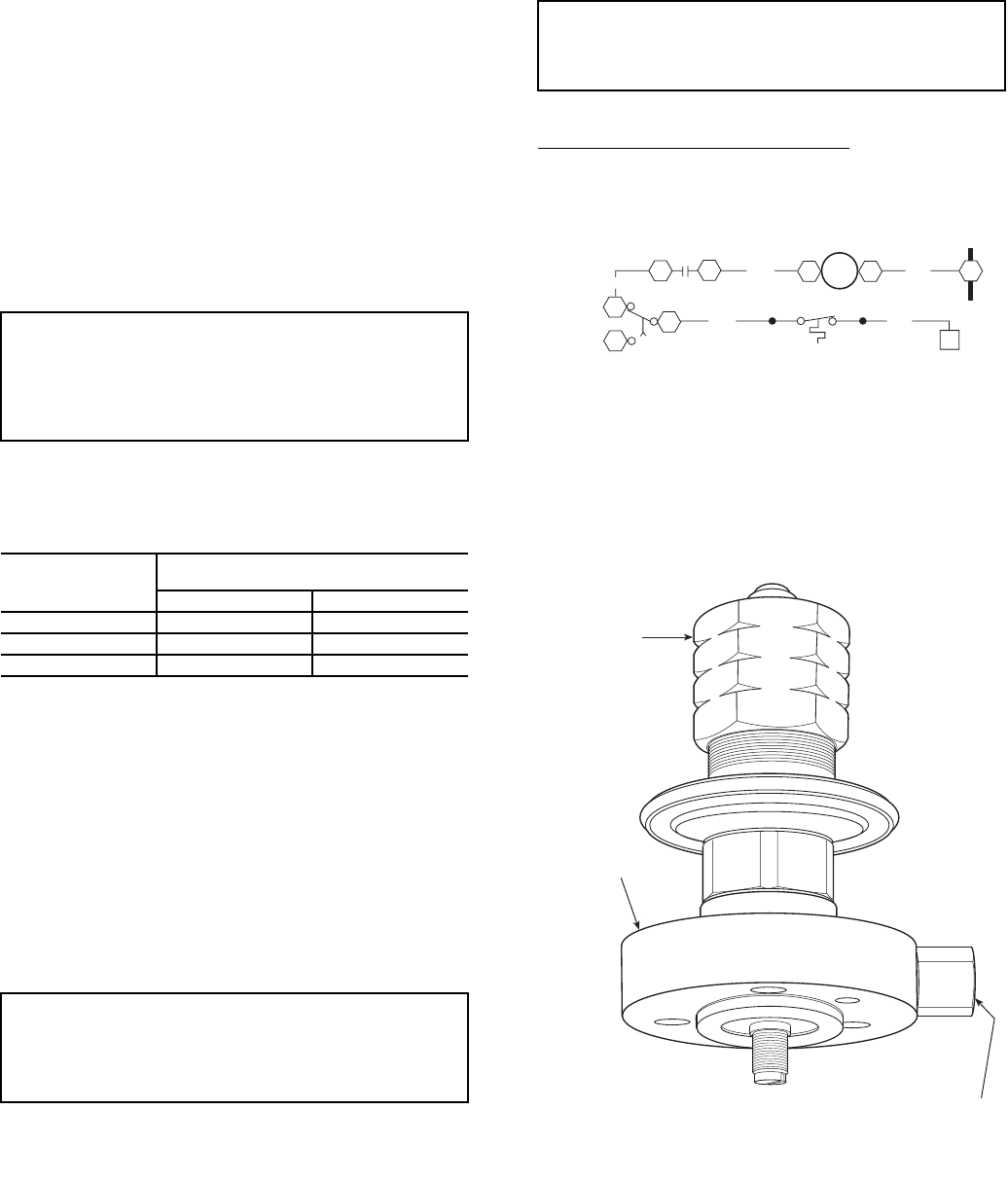

CAPACITY CONTROL VALVE (Fig. 9) — Valve is con-

trolled by suction pressure and actuated by discharge pressure.

Each valve controls 2 cylinders. On start-up, controlled

cylinders do not load up until differential between suction and

discharge pressures is approximately 25 psi. See Table 5.

CAPACITY CONTROL VALVE ADJUSTMENTS

Control Set Point (Cylinder Load Point)

— Adjustable from

0 to 86 psig. Pressure differential between cylinder load-up

point and cylinder unload point is adjustable from 6 psi

to 16 psi.

IMPORTANT: If the oil pressure switch causes unit lock-

out, determine and correct the cause of the lockout (such as

loss of compressor oil or flooded compressor) before

restarting the unit. Failure to correct the cause of OPS

lockout may constitute abuse. Equipment failure due to

abuse is not covered by warranty.

SWITCH TYPE

PRESSURE CHANGE AFFECTING

SWITCH POSITION (psig)

Closed Open

High Pressure

210 (±10) 290 (±10)

Low Pressure

70 (±4) 60 (±4)

Oil Pressure

611

IMPORTANT: Never open any switch or disconnect that

will deenergize the crankcase heater unless unit is being

serviced or is to be shut down for a prolonged period. After

a prolonged shutdown or a service job, energize the crank-

case heater for 24 hours before starting the compressor.

IMPORTANT: Do not use automatic pumpdown control

on 06E,07E units equipped with unloader valves. Use

single pumpout or solenoid drop (minimum protection)

control.

CONTROL

SET POINT

ADJUSTMENT

NUT

VALVE BODY

SEALING CAP

(COVERS PRESSURE DIFFERENTIAL

ADJUSTMENT SCREW)

Fig. 9 — Capacity Control Valve

TIMER

CONTACTS

BLU

ORN

B2

B1

CR

46

RED

C1

C2

C2

DTS

BLU

YEL

TB2

6

C2

C1

B

LEGEND

Fig. 8 — Discharge Temperature Sensor (DTS)

C—

Compressor Contactor

CR —

Control Relay

DTS —

Discharge Temperature Sensor

TB —

Terminal Block

•

Splice (in compressor junction box)