For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 13SKU 95424, 95629

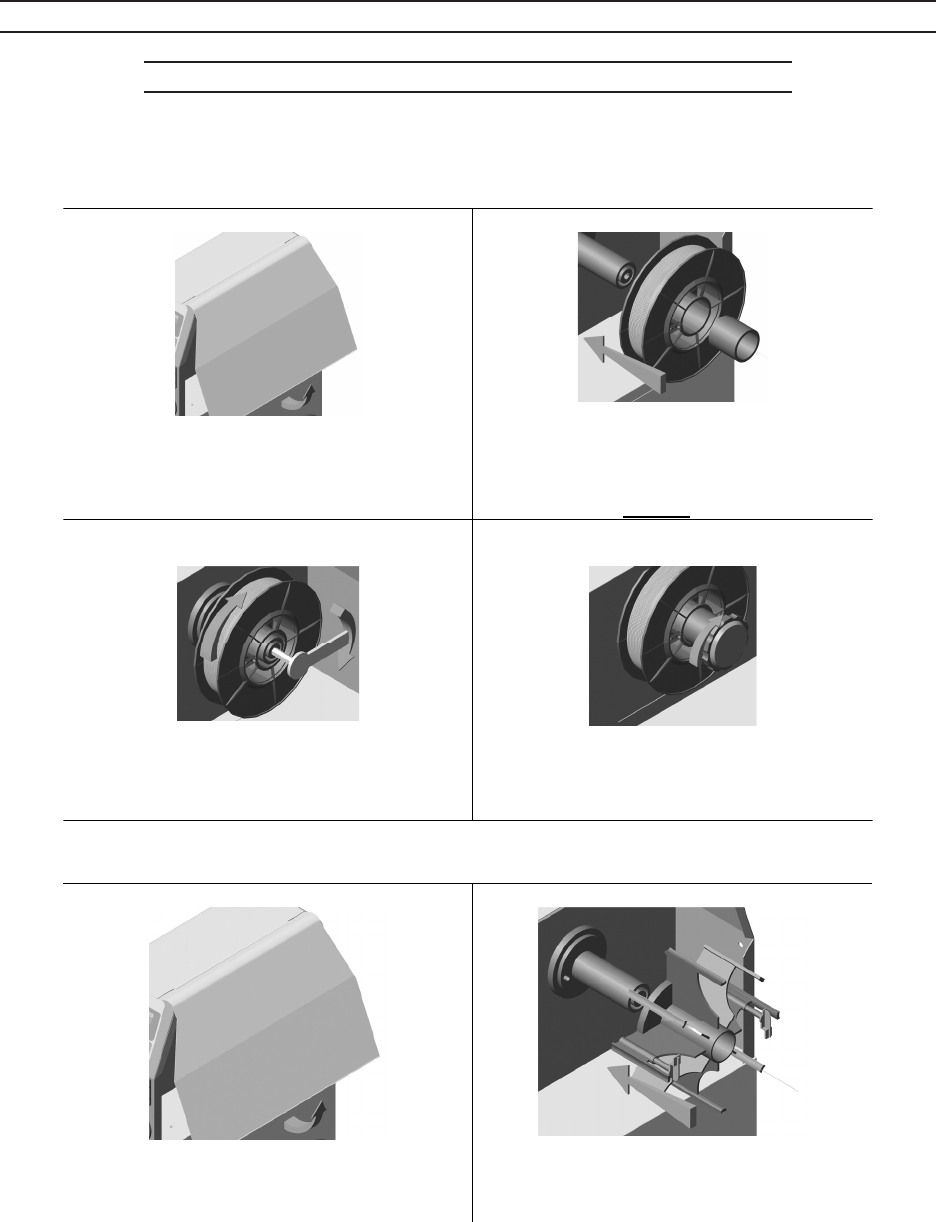

INSTALLING A WIRE SPOOL

Assembling the Wire Spool depends on whether you are using a 7” Spool or an 11”

Spool.

For use with a 7” Spool:

MIG&ARC 250 AMP - SKU 95424

MIG DUAL 250 AMP – SKU

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 14

TO INSTALL THE WIRE SPOOL

Two variants to expose the Wire Drive Assembly are probable for Spool 200mm (variant A)

and for EN 759 Spool 300mm (variant B) use.

Variant A

1.

Lift the Door (14A) of the Welder to expose

the Wire Drive Assembly.

2.

Insert the Spool and the Pressing Cartridge

onto the Threaded Shaft (11A). Making

sure the Spool's Welding Wire unwinds

from the bottom (clockwise).

3.

When a slight force is needed to turn Spool,

tension is set.

4.

Screw the Fixing Cover into the Threaded

Shaft (11A).

Variant B

1.

Lift the Door (14A) of the Welder to expose

the Wire Drive Assembly.

2.

Insert the Spool′s Holder onto the

Threaded Shaft (11A).

For use with a 11” Spool:

MIG&ARC 250 AMP - SKU 95424

MIG DUAL 250 AMP – SKU

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 14

TO INSTALL THE WIRE SPOOL

Two variants to expose the Wire Drive Assembly are probable for Spool 200mm (variant A)

and for EN 759 Spool 300mm (variant B) use.

Variant A

1.

Lift the Door (14A) of the Welder to expose

the Wire Drive Assembly.

2.

Insert the Spool and the Pressing Cartridge

onto the Threaded Shaft (11A). Making

sure the Spool's Welding Wire unwinds

from the bottom (clockwise).

3.

When a slight force is needed to turn Spool,

tension is set.

4.

Screw the Fixing Cover into the Threaded

Shaft (11A).

Variant B

1.

Lift the Door (14A) of the Welder to expose

the Wire Drive Assembly.

2.

Insert the Spool′s Holder onto the

Threaded Shaft (11A).

ASSEMBLY INSTRUCTIONS (CONTINUED)