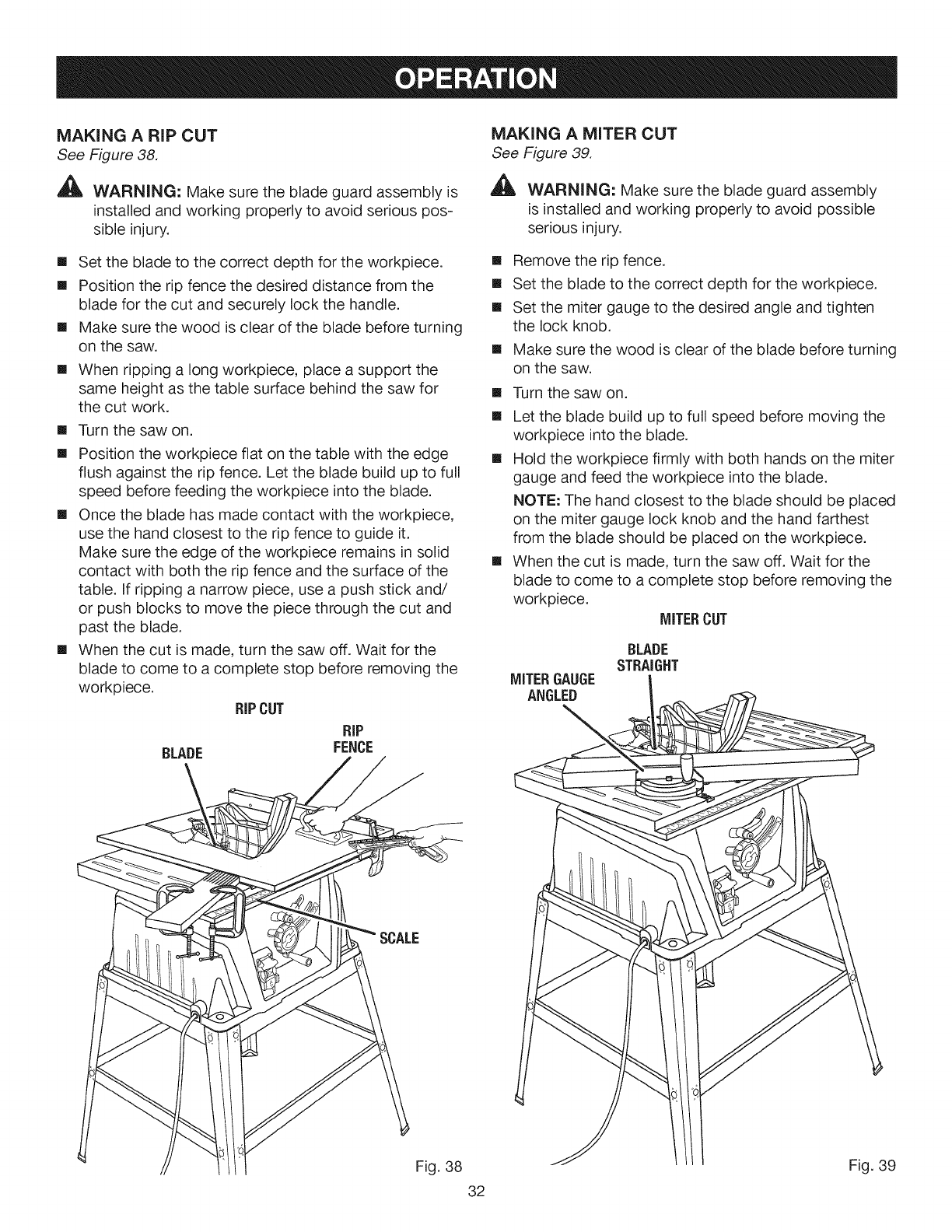

MAKING A RiP CUT

See Figure 38,

_lL WARNING: Make sure the blade guard assembly is

installed and working properly to avoid serious pos-

sible injury.

[] Set the blade to the correct depth for the workpiece.

[] Position the rip fence the desired distance from the

blade for the cut and securely lock the handle.

[] Make sure the wood is clear of the blade before turning

on the saw.

[]

[]

[]

[]

[]

When ripping a long workpiece, place a support the

same height as the table surface behind the saw for

the cut work.

Turn the saw on.

Position the workpiece flat on the table with the edge

flush against the rip fence. Let the blade build up to full

speed before feeding the workpiece into the blade.

Once the blade has made contact with the workpiece,

use the hand closest to the rip fence to guide it.

Make sure the edge of the workpiece remains in solid

contact with both the rip fence and the surface of the

table. If ripping a narrow piece, use a push stick and/

or push blocks to move the piece through the cut and

past the blade.

When the cut is made, turn the saw off. Wait for the

blade to come to a complete stop before removing the

workpiece.

RiPCUT

RIP

BLADE FENCE

MAKING A MITER CUT

See Figure 39.

A

WARNING: Make sure the blade guard assembly

is installed and working properly to avoid possible

serious injury.

[] Remove the rip fence.

[] Set the blade to the correct depth for the workpiece.

[] Set the miter gauge to the desired angle and tighten

the lock knob.

[]

Make sure the wood is clear of the blade before turning

on the saw.

[] Turn the saw on.

[]

Let the blade build up to full speed before moving the

workpiece into the blade.

[] Hold the workpiece firmly with both hands on the miter

gauge and feed the workpiece into the blade.

NOTE: The hand closest to the blade should be placed

on the miter gauge lock knob and the hand farthest

from the blade should be placed on the workpiece.

[] When the cut is made, turn the saw off. Wait for the

blade to come to a complete stop before removing the

workpiece.

MITERCUT

BLADE

STRAIGHT

MITERGAUGE

ANGLED

SCALE

Fig. 38

32

Fig. 39