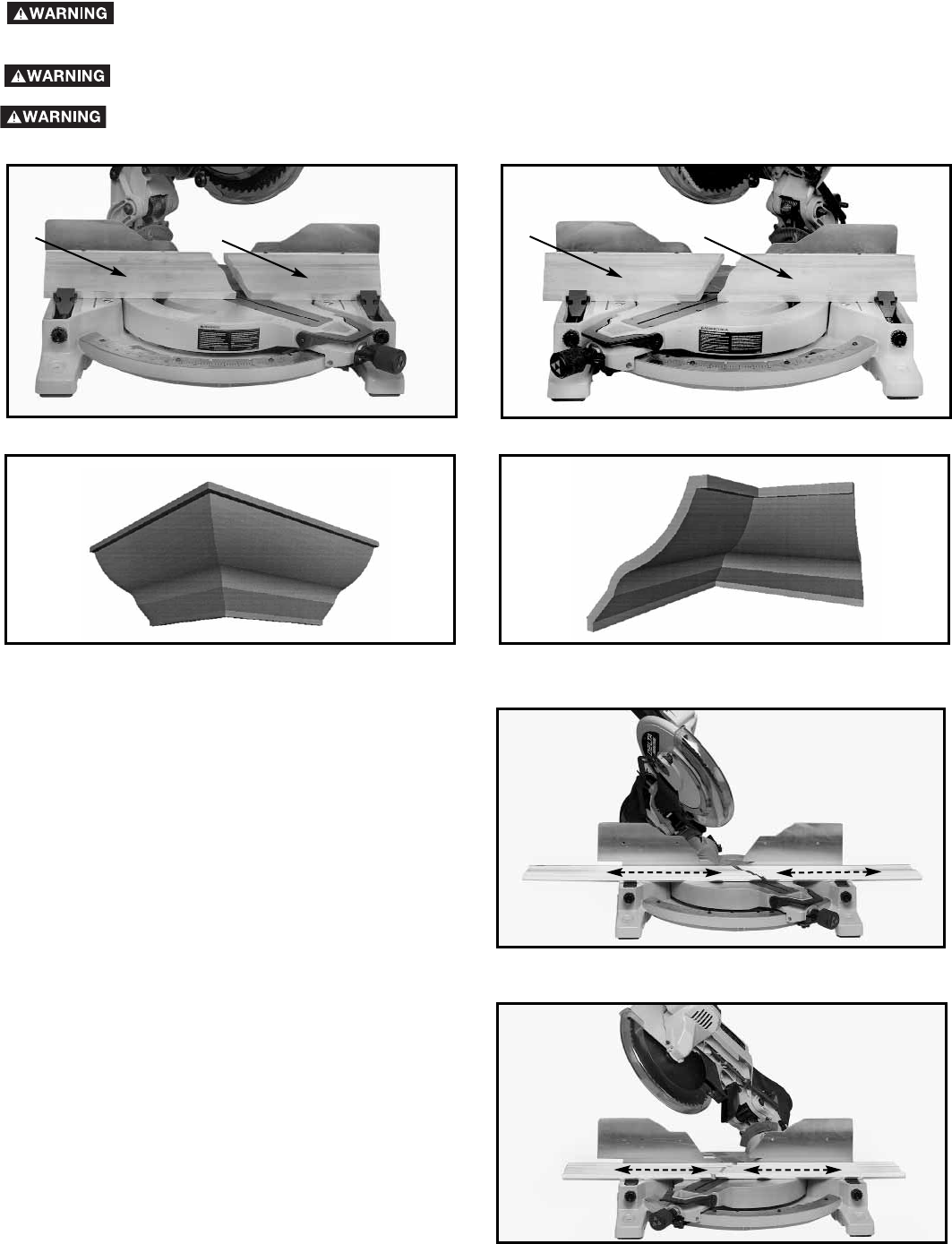

Fig. 46C

Fig. 46D

CB

A

D

A NEW FEATURE FOR THIS TOOL IS CROWN MOULDING STOPS BUILT INTO THE BASE. DELTA DOES

NOT CONSIDER THE CROWN MOULDING STOPS TO BE WORK CLAMPS AND THEY ARE NOT TO BE

USED IN THIS MANNER.

MAKE SURE THAT THE FENCES ARE CLEAR OF THE GUARD AND BLADE BEFORE OPERATING THE SAW.

WHEN CUTTING CROWN MOULDING USING THE CROWN MOULDING STOPS, DO NOT BEVEL THE CUT. THE

CROWN MOULDING STOP FEATURE IS DESIGNED TO MAKE THE CUT WITH THE CUTTINGHEAD AT 90° AND

WITH THE TABLE ROTATED 45°.

Fig. 46A Fig. 46B

A

B D C

Fig. 47

CUTTING CROWN MOULDING

(FLAT POSITION)

One of the many features of the saw is the ease of cutting

crown moulding. The following is an example of cutting

both inside and outside corners on 52°/38° wall angle

crown moulding.

1. Move the table to the 31.62° right miter position and

lock the table in position. NOTE: A positive stop is

provided to find this angle quickly.

2. Tilt the saw blade to the 33.86° left bevel position and

tighten bevel lock handle. NOTE: A triangle indicator

is provided on the bevel scale to find this angle

quickly.

3. Place the crown moulding on the table with the

CEILING EDGE of the moulding against the fence,

and make the cut, as shown in Fig. 47.

NOTE: The piece of crown moulding used for the outside

corner will always be on the right hand side of the

blade, as shown at (A) Fig. 47. The piece of crown

moulding used for the inside corner will always be on

the left hand side of the blade, as shown at (B) Fig.

47.

4. To make the matching halves of the inside and

outside corners, rotate the table to the 31.62° left

miter position.

NOTE: A positive stop is provided to find this angle

quickly. The saw blade is already tilted to the 33.86°

bevel position from the previous cut.

D

C

B

A

Fig. 48

18