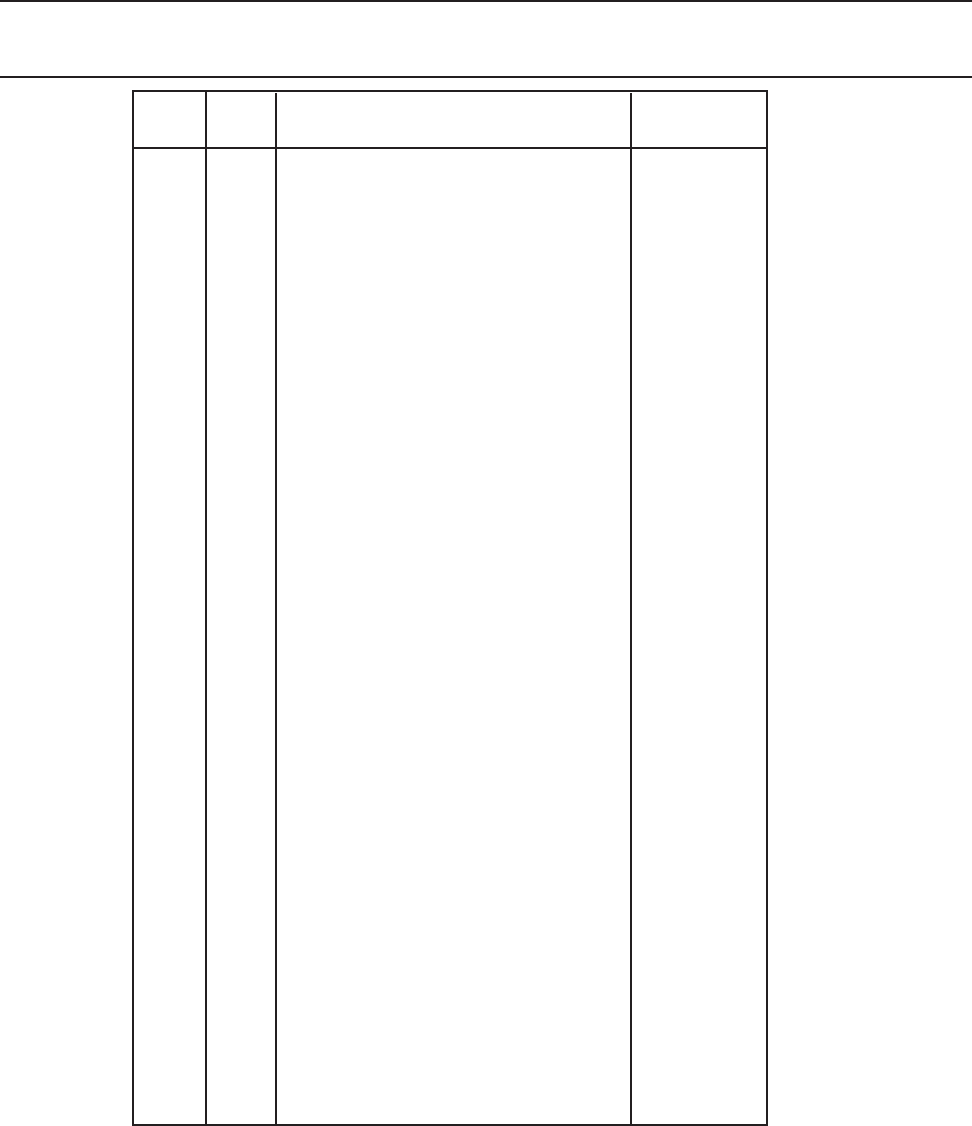

18

BOARD I/O # DESCRIPTION TYPE

#

1 1 Compressor Start OUTPUT

1 2 Oil Pump Start OUTPUT

1 3 Capacity Increase OUTPUT

1 4 Capacity Decrease OUTPUT

1 5 Volume Increase OUTPUT

1 6 Volume Decrease OUTPUT

1 7 Oil Sump Heater OUTPUT

1 8 Alarm OUTPUT

2 9 Slide Valve Set point #1 (Economizer) OUTPUT

2 10 Slide Valve Set point #2 (Hot Gas) OUTPUT

2 11 Slide Valve Set point #3 OUTPUT

2 12 Slide Valve Set point #4 OUTPUT

2 13 Liquid Injection #1 OUTPUT

2 14 Liquid Injection #2 OUTPUT

2 15 Remote Enabled OUTPUT

2 16 VRS Oil solenoid for old retrofit applications OUTPUT

3 17 Comp Motor Starter Auxiliary Contact INPUT

3 18 High Level Shutdown INPUT

3 19 Oil Level Float Switch #1 INPUT

3 20 Oil Level Float Switch #2 INPUT

3 21 Remot Setpoint #1/#2 Selection INPUT

3 22 Remote Start/Stop INPUT

3 23 Remote Capacity Increase INPUT

3 24 Remote Capacity Decrease INPUT

4 25 Condenser Step #1 OUTPUT

4 26 Condenser Step #2 OUTPUT

4 27 Condenser Step #3 OUTPUT

4 28 Condenser Step #4 OUTPUT

4 29 Auxiliary Input #1 INPUT

4 30 Auxiliary Input #2 INPUT

4 31 Auxiliary Input #3 INPUT

4 32 Auxiliary Input #4 INPUT

5 33 Auxiliary Output #1 OUTPUT

5 34 Auxiliary Output #2 OUTPUT

5 35 Auxiliary Output #3 OUTPUT

5 36 Auxiliary Output #4 OUTPUT

5 37 Auxiliary Input #5 INPUT

5 38 Auxiliary Input #6 INPUT

5 39 Auxiliary Input #7 INPUT

5 40 Auxiliary Input #8 INPUT

COMPRESSOR START OUTPUT – When the Vission 20/20 signals the compressor to start, this output is energized.

When the Vission 20/20 signals the compressor to stop, this output is de-energized.

OIL PUMP START OUTPUT - When the Vission 20/20 signals the oil pump to start, this output is energized. When

the Vission 20/20 signals the oil pump to stop, this output is de-energized.

Digital Input/Output