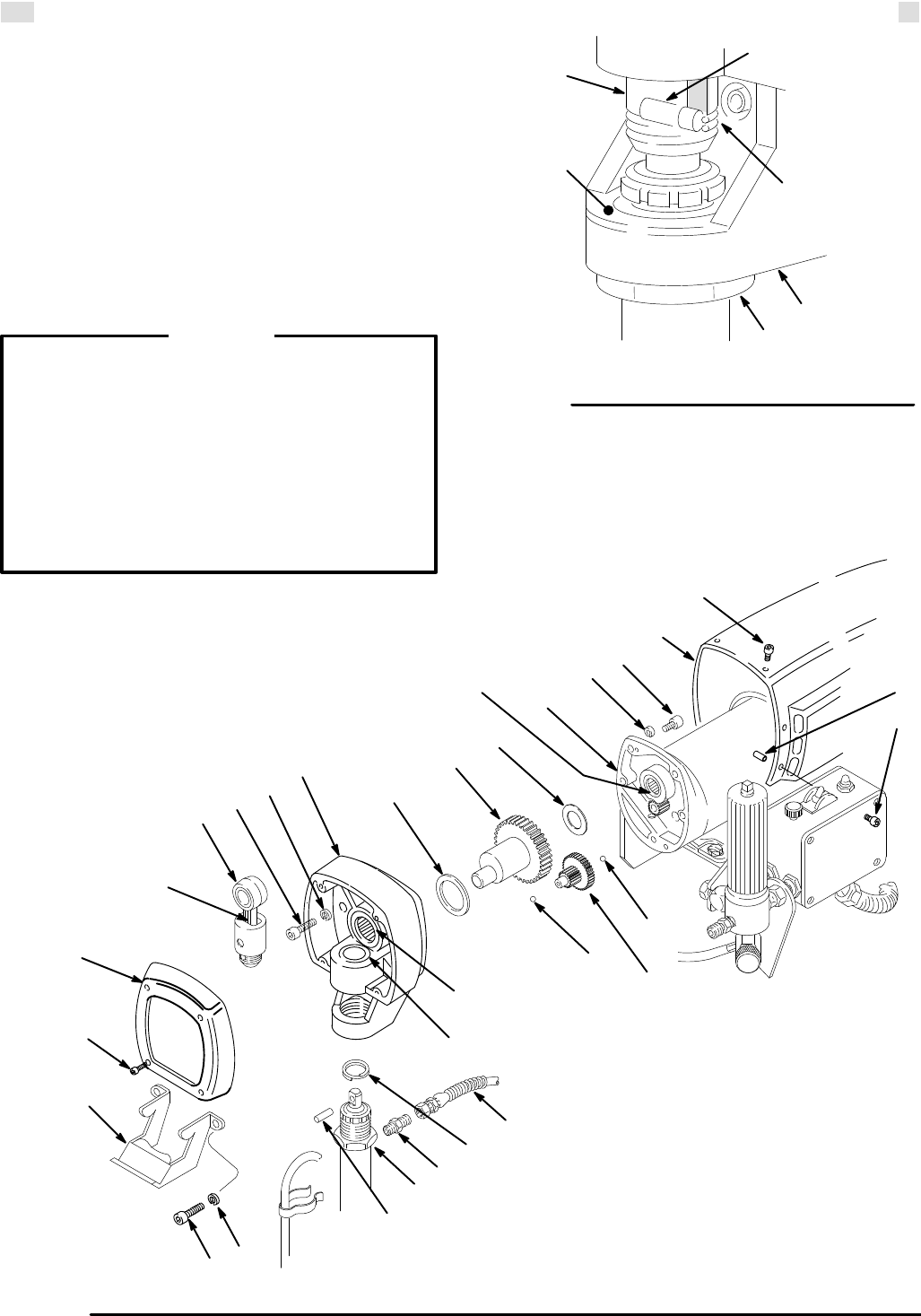

FILL CA

VITY WITH

SAE 10

NON–DETERGENT

MOT

OR OIL

Fig

33–2

39

68

8

71

8

75

18

14

58

69a

69

69b

73

18

25

70

57

22

41

43

42

63

LUBRICATE

LIBERALLY

P

ACK

WITH GREASE

LIBERALL

Y P

ACK

WITH GREASE

LIBERALL

Y P

ACK

WITH GREASE

01580

60

44

33

32

30

307–758

33

DRIVE

HOUSING, CONNECTING ROD & CRANKSHAFT REPLACEMENT

14. Screw

the displacement pump about 3/4 of the way

into

the drive housing (73). Hold the pin (43) up to the

pin hole in the connecting rod assembly (70) and

continue screwing in the pump until the pin slides

easily into the hole. Back off the pump until the top

threads

of

the pump cylinder are flush with the face of

the

drive housing and the outlet nipple

(39) is facing

back.

Push the retaining spring (42) into the groove

all the way around the connecting rod. Tighten the

locknut

(41) very tight – about 70 ft-lb (95

N.m) – with

a 1-3/4 in. open end wrench and a light hammer

.

See

Fig

33–1 and 33–2.

Be sure the retaining spring (42) is firmly in the

groove all the way around, to prevent the pin (43)

from

working loose due to vibration.

See Fig 33–1.

If

the pin works loose, it or other parts could break of

f

due to the force of the pump action. These parts

could

be projected through the air and result in seri

-

ous

bodily injury or property damage, including dam

-

age

to the pump connecting rod or bearing housing.

WARNING

15. Reinstall

the remaining parts.

42

70

43

73

Fig 33–1

FACE

OF

BEARING

HOUSING

41

TORQUE TO

70 ft-lb (95 N.m)