307–758 37

DISPLACEMENT PUMP REPAIR

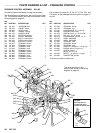

3. Tighten the packing retaining nut (211) against the

piston

valve (222) to 19 ft-lb (27 N.m).

Note

the alignment

of the

piston (222) to the pack

-

ing retainer nut (211). Maintain this alignment

through

Steps 5, 6 and 7.

4. Place

the ball (225)

on the piston valve (222). See Fig

37–1.

CAUTION

Step

5 is critical. Follow the procedure carefully to

avoid damaging the packings by overtightening.

5. Apply one drop of adhesive, supplied, to the piston

valve

threads. Then hand tighten the valve assembly

into

the piston rod just until

the nut (21

1) contacts the

rod.

See Fig 37–1.

211

Fig 37–1

POLY

*212

LIPS F

ACE UP

0029

222

203*

LIPS F

ACE DOWN

215*

225*

APPLY ONE DROP

OF SEALANT T

O

THESE THREADS

224

TORQUE TO

10.5 in-lb (1.2 N.m)

to seat the packing,

and then back of

f and

tighten finger tight.

*210

214*

206*

LEATHER

LIPS F

ACE UP

6. Place

the flats at the top of the rod in a vise.

7. Use a wrench to CAREFULLY tighten the nut (211)

onto the piston rod to 19 ft-lbs (25 N.m). See Fig

37–2.

Use two wrenches to maintain the alignment men-

tioned

in Step 7, above.

Fig 37–2

224

211

TORQUE

NUT

AGAINST ROD T

O

19 ft–lb (27 N.m)

DO NOT ALLOW NUT

(211)

T

O MOVE

WHEN

INSTALLING

PIST

ON

ONTO ROD

01238

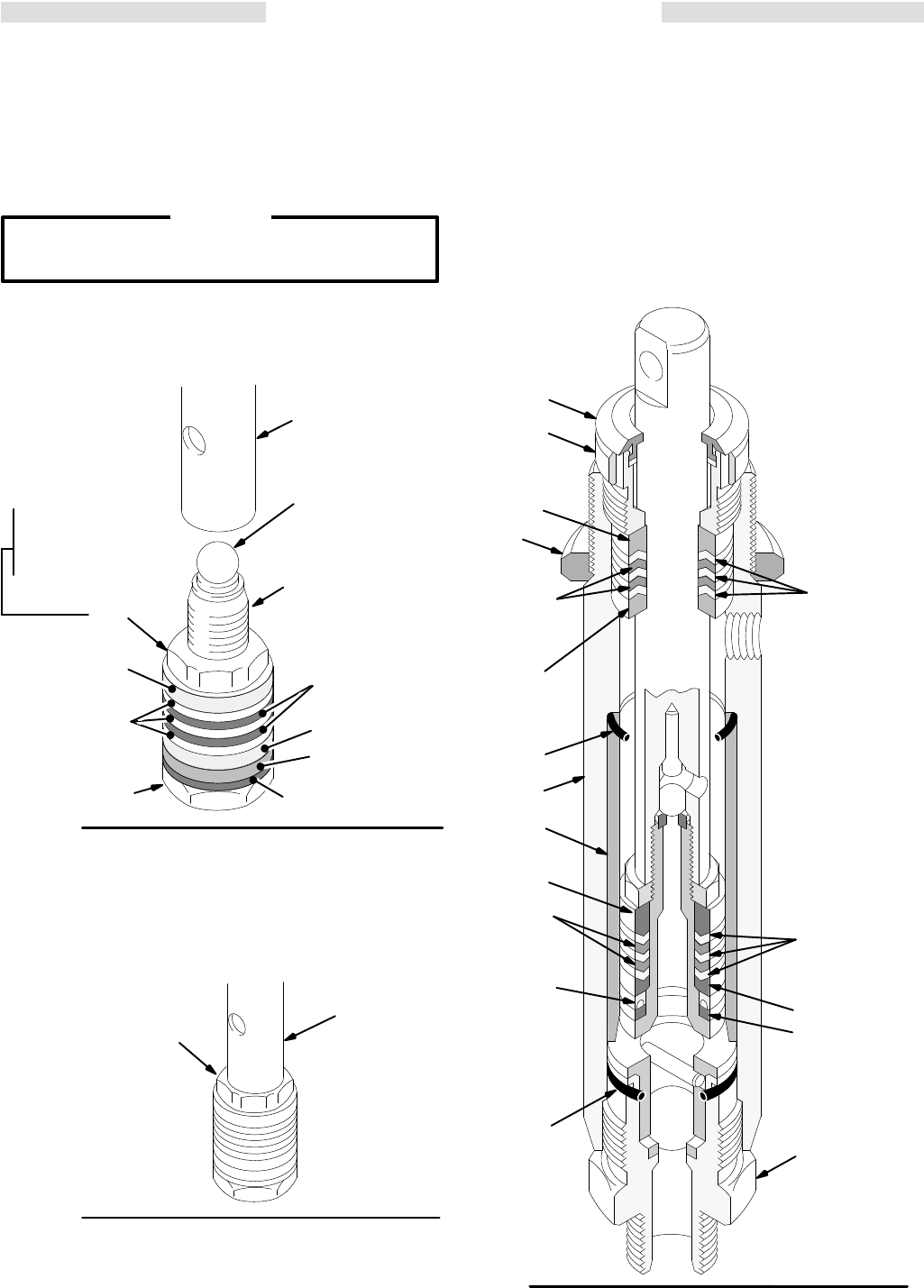

8. Stack the male gland (208*), alternate packings

(213*,207*), and female gland (209*) into the top of

the

cylinder (219). See Fig 37–3.

9. Install

the packing

nut (216) and plug (205), but leave

loose

for now

.

See Fig 37–3.

10. Coat the piston rod and packings with oil. Carefully

slide the assembly INTO THE TOP OF THE

SLEEVE.

NOTE: The

tapered end of the sleeve is the bottom of

it.

See

Fig 38–1.

11. Place a new o–ring (217*) firmly in the cylinder

groove.

See Fig 37–3.

219

Fig 37–3

212*

POLY

LIPS

MUST

F

ACE UP

213*

POLY

LIPS MUST

F

ACE UP

205

*206

LEATHER

LIPS MUST

F

ACE UP

*203

U–CUP SEAL

LIPS MUST

FACE DOWN

215*

214*

*202

*217

*208

*207

LEATHER

LIPS MUST

FACE DOWN

*209

41

218

216

211

TORQUE TO:

67 ft-lb

(90 N.m)

*210

01197