Supply System Operation

313526J 19

Supply System Operation

Pressure Relief Procedure

1. Lock the gun/valve trigger.

2. For D200s, D200, S20, and D60 Air Controls: See

F

IG

. 3, page 12.

a. Close the air motor slider valve (BF) and the

main air slider valve (BA).

b. Set the ram director valve (BC) to DOWN. The

ram will slowly drop.

c. Jog the director valve up and down to bleed air

from ram cylinders.

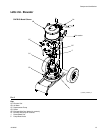

3. For L20c Air Controls: See F

IG

. 7, page 14.

a. Close the air motor valve (DC) and the elevator

director valve (DD). The ram will slowly drop.

4. Unlock the gun/valve trigger.

5. Hold a metal part of the gun/valve firmly to the side

of a grounded metal pail, and trigger the gun/valve

to relieve pressure.

6. Lock the gun/valve trigger.

7. Open the fluid line drain valve and the pump bleeder

valve (P). Have a container ready to catch the drain-

age.

8. Leave the pump bleeder valve (P) open until ready

to spray again.

If you suspect that the spray tip/nozzle or hose is com-

pletely clogged, or that pressure has not been fully

relieved after following the steps above, very slowly

loosen the tip guard retaining nut or hose end coupling

and relieve pressure gradually, then loosen completely.

Now clear the tip/nozzle or hose.

Flush Before Using Equipment

The pump was tested with lightweight oil, which is left in

the fluid passages to protect parts. To avoid contaminat-

ing fluid with oil, flush the pump with a compatible sol-

vent before use. See pump manual for flushing

directions.

Start and Adjust Ram

D200 3 in. and D200s 6.5 in. Dual Post

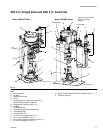

1. Refer to F

IG

. 1 and F

IG

. 3. Close all air regulators

and air valves.

2. Open main air slider valve (BA) and set ram air reg-

ulator (BB) to 40 psi (0.28 MPa, 2.8 bar). Set direc-

tor valve handle (BC) to UP and let the ram rise to

its full height. 2-Button Interlock: If the system has

this feature, ram will stop as it nears the top. Press

and hold both buttons to raise ram completely. See

F

IG

. 3 on page 12.

3. Lubricate the platen seals (D) with grease or other

lubricant compatible with the fluid you will pump.

4. Remove the drum cover and smooth the surface of

the fluid with a straightedge.

5. Put a full drum of fluid on the ram base, slide it back

against the drum stops, and center it under the

platen (D). An optional drum roller kit is available for

D200 and D200s supply systems to make it easier

to load the drum on the base. Order Kit 255627.

Moving parts can pinch or amputate fingers. When the

pump is operating and when raising or lowering the

ram, keep fingers and hands away from the pump

intake, platen, and lip of the drum.

To avoid damage to the platen seals, do not use a

drum that is dented or damaged.