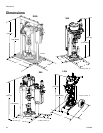

D200S, D200, S20, and D60 Supply Systems Point of Operation Instructions

38 313526J

Start and Adjust Pump

1. Supply fluid to the pump, per the requirements of

your system.

2. Close the air motor slider valve. Set the ram air

regulator to about 50 psi (0.35 MPA, 3.5 bar). Set

the director valve to DOWN.

3. Reduce the air motor regulator pressure and open

the air motor slider valve.

4. Adjust air motor regulator until the pump starts.

5. Cycle the pump slowly until all air is pushed out and

the pump and hoses are fully primed.

6. Release the gun/valve trigger and lock the trigger

safety. The pump should stall against pressure.

7. If the pump fails to prime properly, open the pump

bleed valve slightly. Use the bleed hole, on the

underside of the valve, as a priming valve until the

fluid appears at the hole. Close the plug.

8. With the pump and lines primed, and with adequate

air pressure and volume supplied, the pump will

start and stop as you open and close the gun/valve.

In a circulating system, the pump will speed up or

slow down on demand, until the air supply is shut

off.

9. Use the air motor regulator to control the pump

speed and the fluid pressure. Always use the lowest

air pressure necessary to get the desired results.

Higher pressures cause premature tip/nozzle and

pump wear.

Change Drums

1. Close the air motor slider valve to stop the pump.

2. Set ram director valve to UP to raise the platen and

immediately press and hold the blowoff air button

until the platen is completely out of drum. Use mini-

mum amount of air pressure necessary to push the

platen out of the drum.

3. Release the blowoff air button and allow the ram to

rise to its full height. 2-Button Interlock: If system

has this feature, the ram will stop as it nears the top.

Press and hold both buttons to raise ram com-

pletely.

4. Remove empty drum.

5. Inspect platen and, if necessary, remove any

remaining material or material build–up.

6. Go to Step 4 of Start and Adjust Ram.

Remote DataTrak Operation

Key Functions When in Run Mode

1. To enter Prime Mode, press and release .

a. When a new drum is installed, press and hold

while in Prime Mode to reset the drum vol-

ume remaining to the drum fill volume.

b. To exit Prime Mode, press . The Prime sym-

bol will disappear and the LED will stop flashing;

the screen will return to Run Mode.

2. To reset the job total counter, press and hold

from Run Mode for 3 seconds.

3. To enter Setup Mode, press and hold for 3 sec-

onds.

4. To enter Diagnostic Mode, press and release .

The system will enter Diagnostic Mode only if there

are active warnings/alarms.

Keep hands and fingers away from the priming piston

during operation and whenever the pump is charged

with air. Follow Pressure Relief Procedure before

checking, clearing, or cleaning the priming piston.

To reduce the risk of fluid injection, do not use your

hand or fingers to cover the bleed hole on the under-

side of the bleed valve body when priming the pump.

Use the handle or a crescent wrench to open and close

the bleed plug.

Always use lowest possible fluid pressure to bleed

air out of pump.

Excessive air pressure in the material drum could

cause the drum to rupture, causing serious injury.

The platen must be free to move out of the drum.

Never use drum blowoff air with a damaged drum.