Gun Setup

Check Fluid Re

sistivity

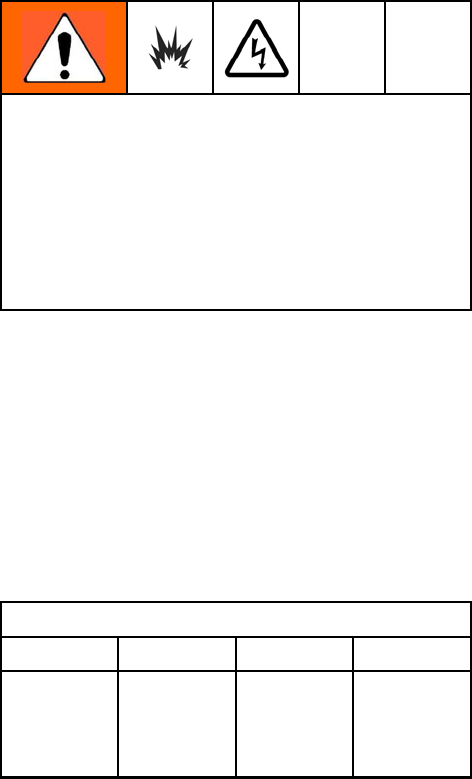

To reduce the risk of fire, explosion, or electric

shock, check the fluid resistivity in a non-hazardous

area only. Resistance Meter 722886 and Probe

722860 are not approved for use in a hazardous

area.

Failure to follow this warning could cause fire,

explosion, or electric shock and result in serious

injury and property damage.

Graco Part No. 722886 Resistance Meter and

722860 Probe are available as accessories to check

that the resistivity of the fluid being sprayed meets

the requirements of an electrostatic air-assisted

spray system.

Follow the instructions included with the meter and

probe. Readings of 25 megohms-cm and above

provide the best electrostatic results.

Table 4 . Fluid Resistivity Levels

Megohms-cm

1–5 5–25 25–200 200–2000

Test elec-

trostatic

perfor-

mance

Good elec-

trostatic

results

Best elec-

trostatic

results

Good elec-

trostatic

results

Check Fluid Vi

scosity

To check fluid viscosity you will need:

• a viscosity cu

p

• a stopwatch.

1. Completely submerge the viscosity cup in

the fluid. Lift the cup out quickly, starting the

stopwatch as soon as the cup is completely

removed.

2. Watch the stream of fluid coming from the bottom

of the cup. As soon as there is a break in the

stream, shut off the stopwatch.

3. Record the fluid type, elapsed time, and size of

the viscosity cup.

4. If the viscosity is too high or too low, contact the

material supplier. Adjust as necessary.

Flush Before Using Equipment

The equipment was tested in fluid at the factory. To

avoid contaminating your fluid, flush the equipment

with a compatible solvent before using the equipment.

26 3A2495C