Repair

Fluid Tube Removal and Replacement

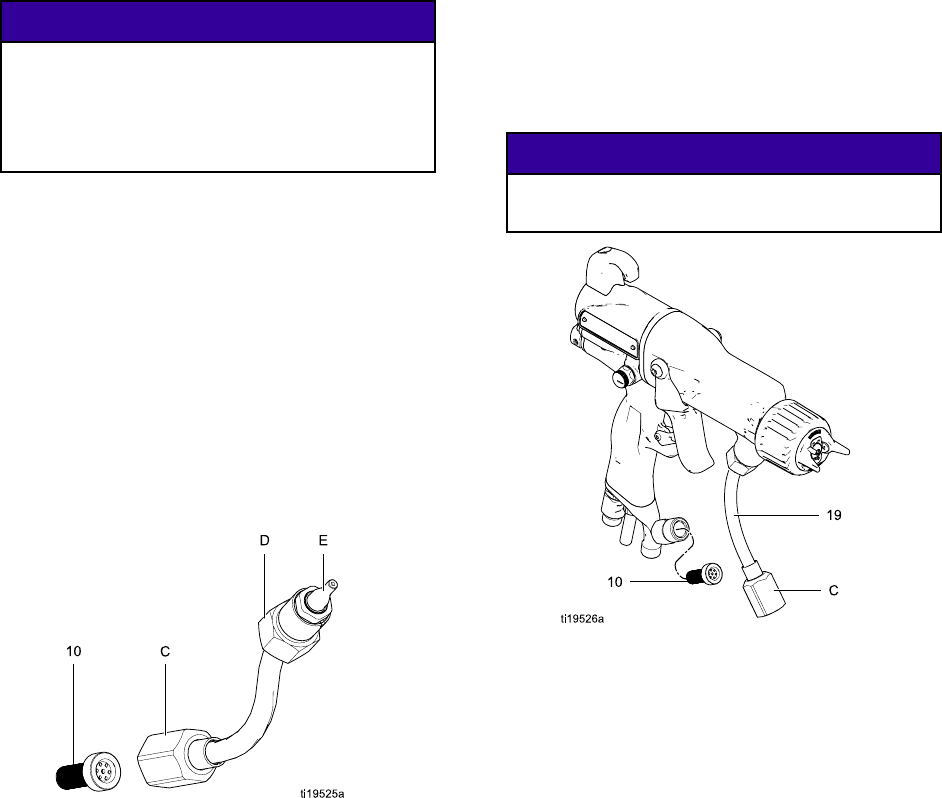

1. See Prepare th

e Gun for Service, page 39.

2. Disconnect th

e bottom fluid tube nut (C).

3. Carefully uns

crew the top fluid tube nut (D).

NOTICE

Be careful not to damage the fluid tube

assembly (19) when cleaning or installing

it, especially the sealing surface (E). If the

sealing surface is damaged, the entire fluid

tube assembly must be replaced.

4. Apply diel

ectric grease (57) to the entire length of

the plasti

c extension on the fluid tube.

5. Apply low s

trength sealant to the fluid tube nut

threads.

6. Install t

he fluid tube into the gun barrel and

tighten t

he top nut (D) until snug, then 1/2 turn

tighter.

There will be a gap between the nut and

barrel.

Do not over-tighten the nut.

7. Make sur

e the fluid filter (10) is in place in the

fluid fitt

ing. Tighten the bottom nut (C) securely

onto the

fitting. Make sure the top nut remains

tight.

Figure 25 Fluid Tube

Fluid Filter Replacement

1. See Prepare th

e Gun for Service, page 39.

2. Disconnect th

e bottom fluid tube nut (C).

3. Remove the flui

d filter (10) from the fluid fitting.

Clean or repl

ace the filter, as needed.

4. Install the fl

uid filter (10) in the fluid fitting. Tighten

the bottom nu

t (C) onto the fitting and torque to

140–150 in-l

b (15.8–16.9 N•m). Make sure the

top nut rema

ins tight at 20–30 in-lb (2.3–3.4 N•m).

NOTICE

Be sure the fluid tube (19) is not twisted after

tightening the bottom nut (C).

Figure 26 Replace Fluid Filter

4

2

3A2495C