22 308-084

SERVICE

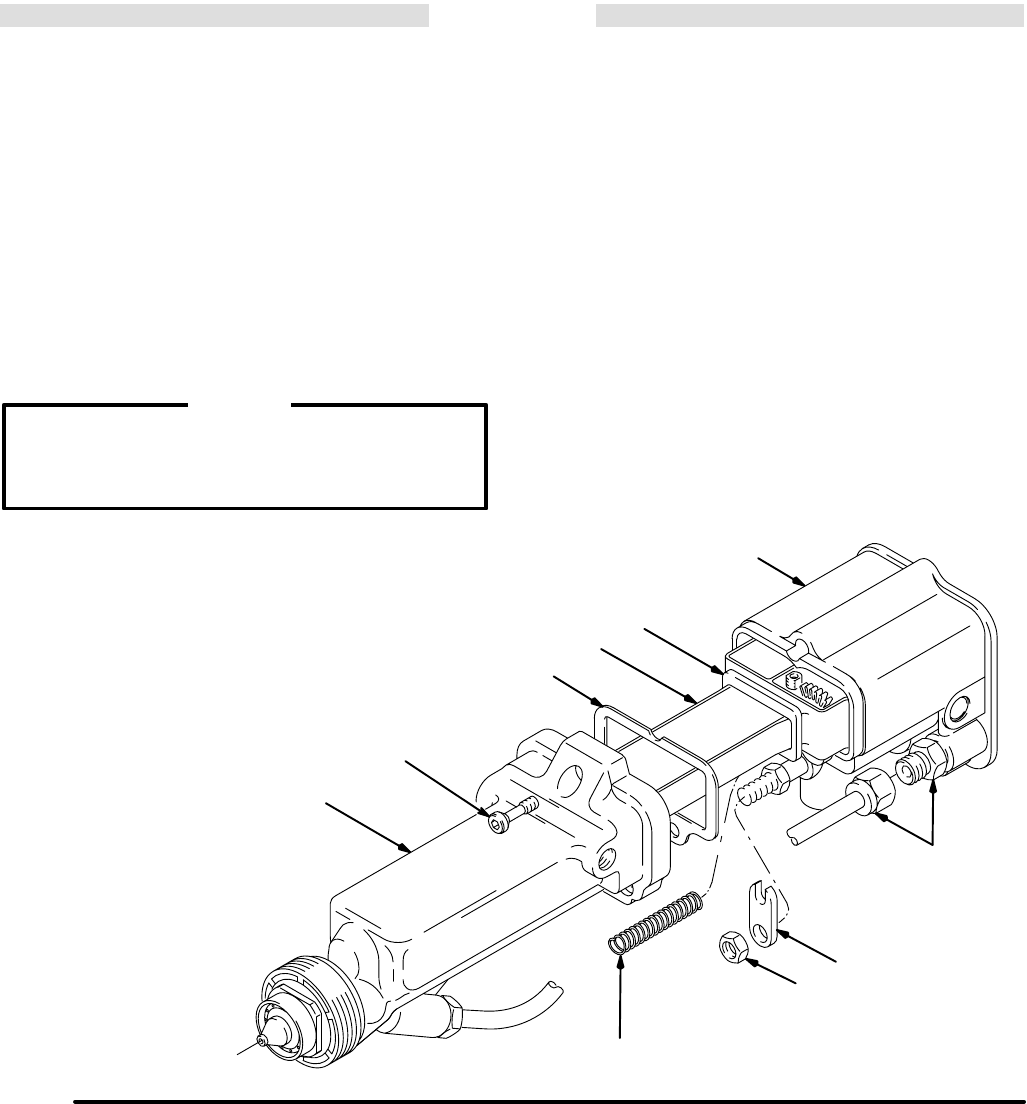

Barrel Installation

1. Be

sure the gaskets (23 & 40a) and spring (1

1) are in

place.

See Fig 20 . Replace if damaged.

2. Place

the barrel (10) over the power supply (40) and

onto

the gun body (39). Make sure the fluid rod spring

(11)

is seated properly

.

3. Tighten the three socket head cap screws (15)

oppositely

and evenly with the ball end wrench (46).

Tighten the cap screws to 18 in-lbs (2 N Sm)

MAXI-

MUM

(about a half turn past snug).

DO NOT

over

tighten.

CAUTION

To

avoid damaging the gun,

DO NOT

over

tighten

the cap screws (15). Tighten the screws to 18 in-

lbs (2 N Sm)

MAXIMUM

(about a half turn past

snug),

using the wrench (46) supplied only

.

4.

Install the fluid tube back into the fluid fitting (21).

5. Install

the actuator arm (29) and jam nut (25), with the

jam

nut assembled flush to the end of the rod.

There

should be about a 1/16 in. gap between the ac

-

tuator

arm (29) and the nut on the fluid shaft. When

the gun is triggered, the electrode needle should

draw back 3 to 4 mm. If necessary , adjust the jam

nuts

to obtain these dimensions.

The

jam nut

must be tightened securely to prevent it

from

loosening during operation.

6. T

est the gun resistance as instructed on page 16.

Fig 20

KEY

10 Gun

Barrel

11 Spring

15

Cap Screws

21

Fluid T

ube Fitting

23 Gasket

25

Jam Nut

29

Actuator Arm

39

Gun body

40

Power Supply

40a Gasket

0457

10

15

23

40

40a

39

21

29

25

11