-22- G1021 15" Planer

6. Repeat steps 1-5 for the opposite side of the

roller. Repeat all steps for the outfeed roller.

Feeler gauge measurement should equal 0.040".

TO ADJUST ROLLER HEIGHT:

1. Remove the drive chain cover to access the

roller adjustments on the drive chain side of

the planer. A single socket head cap screw

holds the drive chain cover on. Belt side

adjustments are already accessible.

2. Loosen the roller adjustment check nuts and

turn the roller height setscrews to change

the height of the roller as needed. See

Figure 20.

3. Check roller height according to the above

instructions. Continue turning the setscrew

until the roller is properly adjusted.

4. When the roller is set in the correct position,

re-tighten the check nuts you loosened in

Step 2 above.

5. Check your settings one last time and repeat

steps 1-4 if necessary.

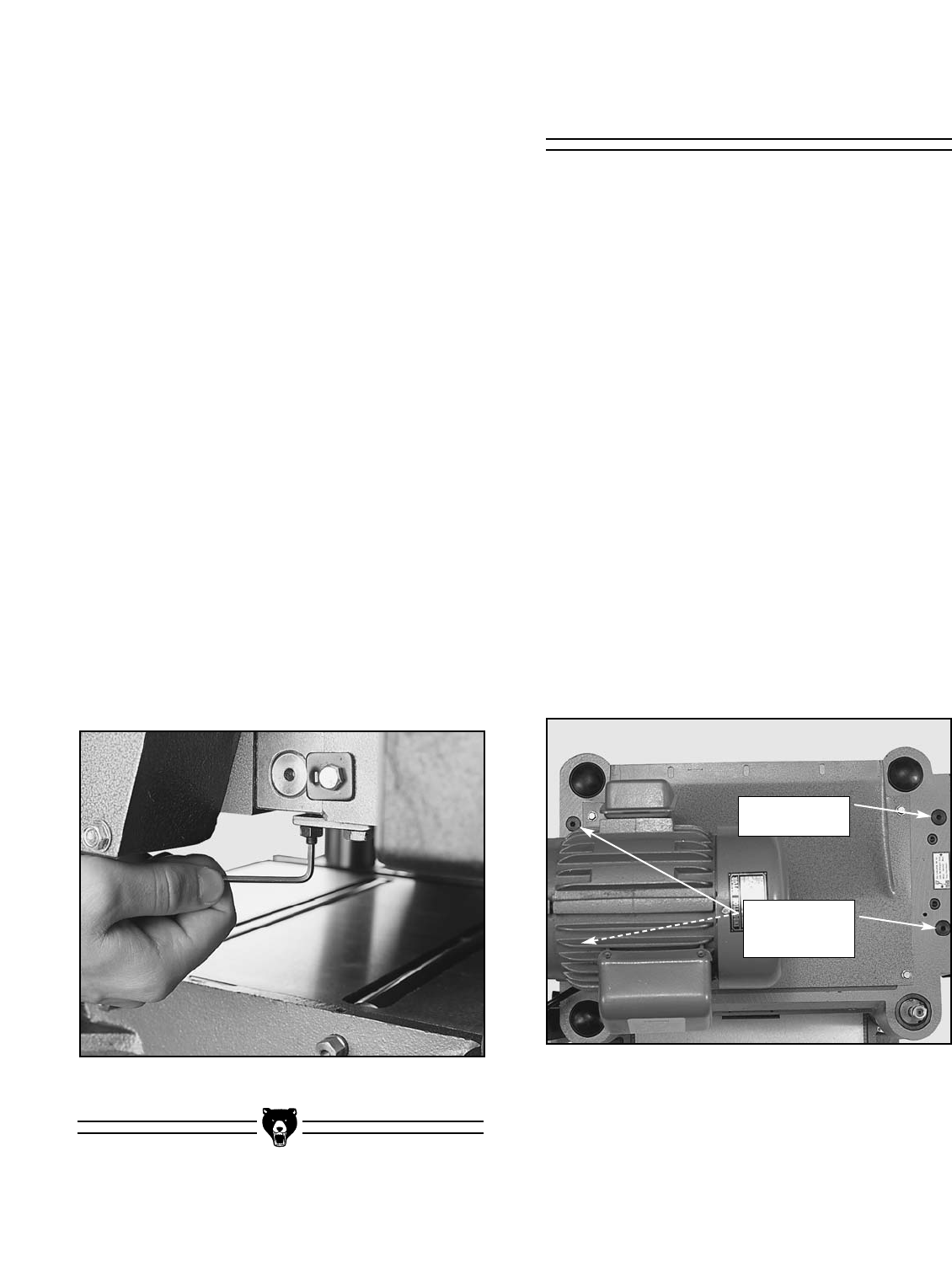

Figure 20. Feed roller height adjustment.

To be effective, the infeed and outfeed rollers

must put pressure on the workpiece as it feeds

through the planer. Too little pressure results in

slipping boards, too much pressure results in

jamming.

Experiment with the best pressure settings for

your work situations. Some rough cut lumber will

feed through fine with relatively few problems,

while other lumber will have more difficulty.

Adjusting roller pressure does not affect height.

TO ADJUST ROLLER PRESSURE:

1. Disconnect the machine from the power

source.

2. Ensure that knives and feed rollers are set

correctly.

3. Unscrew the four large pressure setscrews

on top of the planer body. See Figure 21.

Feed Roller Pressure

Figure 21. Roller pressure adjustment.

Light Pressure

Setscrew

Regular

Pressure

Setscrews