G1021 15" Planer -31-

Once the assembly is complete and the adjust-

ments are done to your satisfaction, you are

ready to test the machine.

Turn on the power supply at the main panel.

Press the START button. Make sure that your fin-

ger is poised on the STOP button, just in case

there is a problem. The planer should run

smoothly, with little or no vibration or rubbing

noises. Strange or unnatural noises should be

investigated and corrected before operating the

machine further.

Test Run

WARNING

DO NOT attempt to investigate or adjust the

machine while it is running. Wait until the

machine is turned off, unplugged and all

working parts have come to a rest before

you do anything!

WARNING

Always wear ANSI-approved safety glasses

or goggles when operating equipment —

particularly when testing new tools or

machinery. Do not allow visitors into your

workshop when testing or operating equip-

ment.

If noises occur that cannot be found by visual

inspection, feel free to contact our service depart-

ment for help.

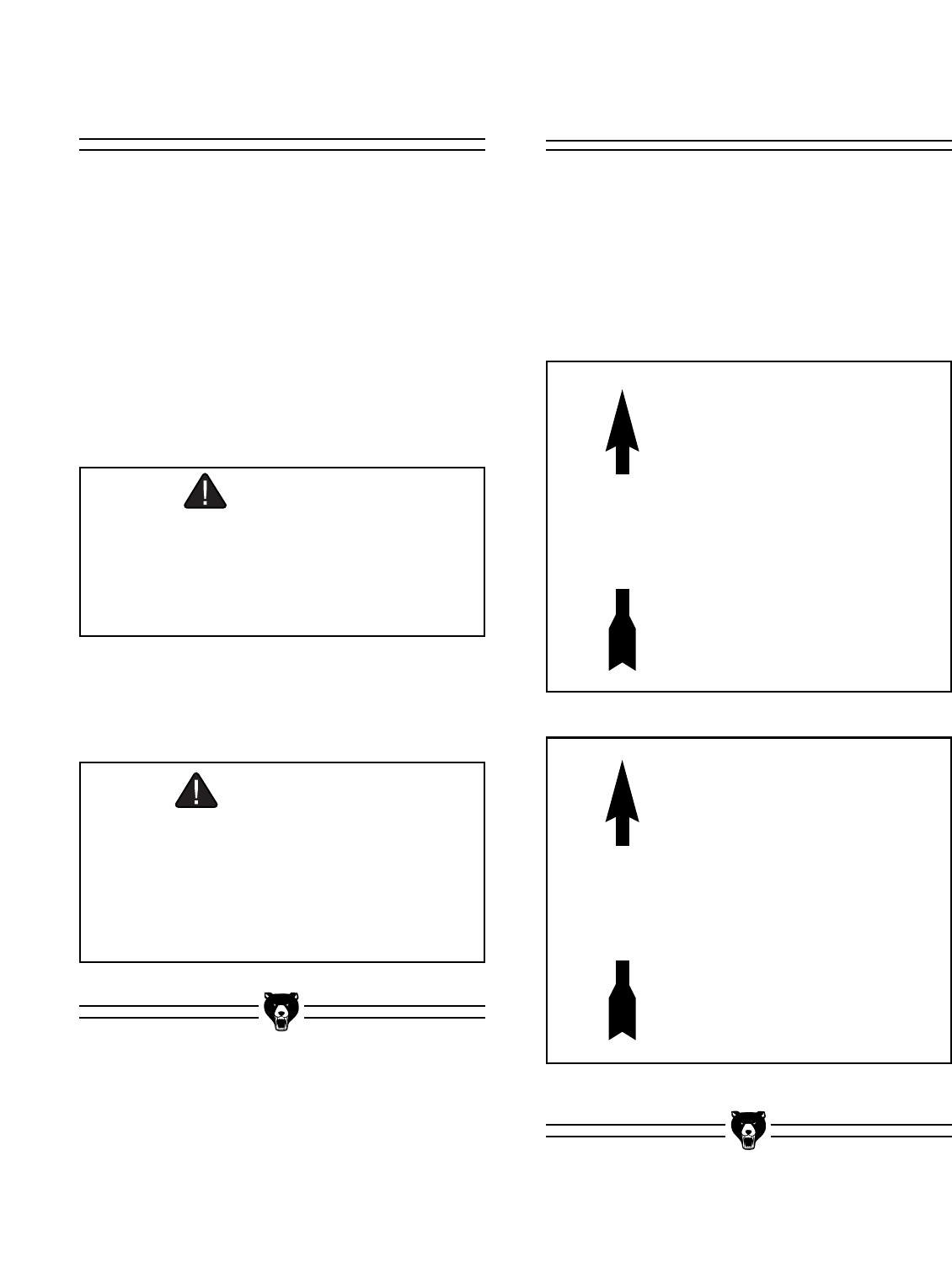

The species of wood, as well as its condition,

have a dramatic effect on planing ability. The

harder the wood (as illustrated by its shear

strength), the more difficult it will be to plane. A

brief listing of common hard and soft woods in

relation to their shear strengths and planing diffi-

culty is listed below.

Type Shear (PSI)

Black Locust 2,480

Sugar Maple 2,330

Pecan Hickory 2,080

White Oak 2,000

White Ash 1,950

Black Cherry 1,700

American Elm 1,510

Black Walnut 1,370

Red Alder 1,080

Basswood 980

Cottonwood 930

Increasing

Difficulty

Figure 37. Common hardwood shear strengths.

Type Shear (PSI)

Western Larch 1,410

Tamarack 1,280

Douglas Fir 1,160

Alaska Cedar 1,130

Sitka Spruce 1,150

Sugar Pine 1,050

Cypress 1,000

Redwood (OG) 940

Red Cedar 860

White Pine 850

Balsam Fir 710

Increasing

Difficulty

Figure 38. Common softwood shear strengths.

Wood Species