G1021 15" Planer -37-

This section covers the most common processing problems encountered in planing and what to do about

them. Do not make any adjustments until planer is unplugged and moving parts have come to a complete

stop.

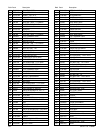

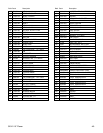

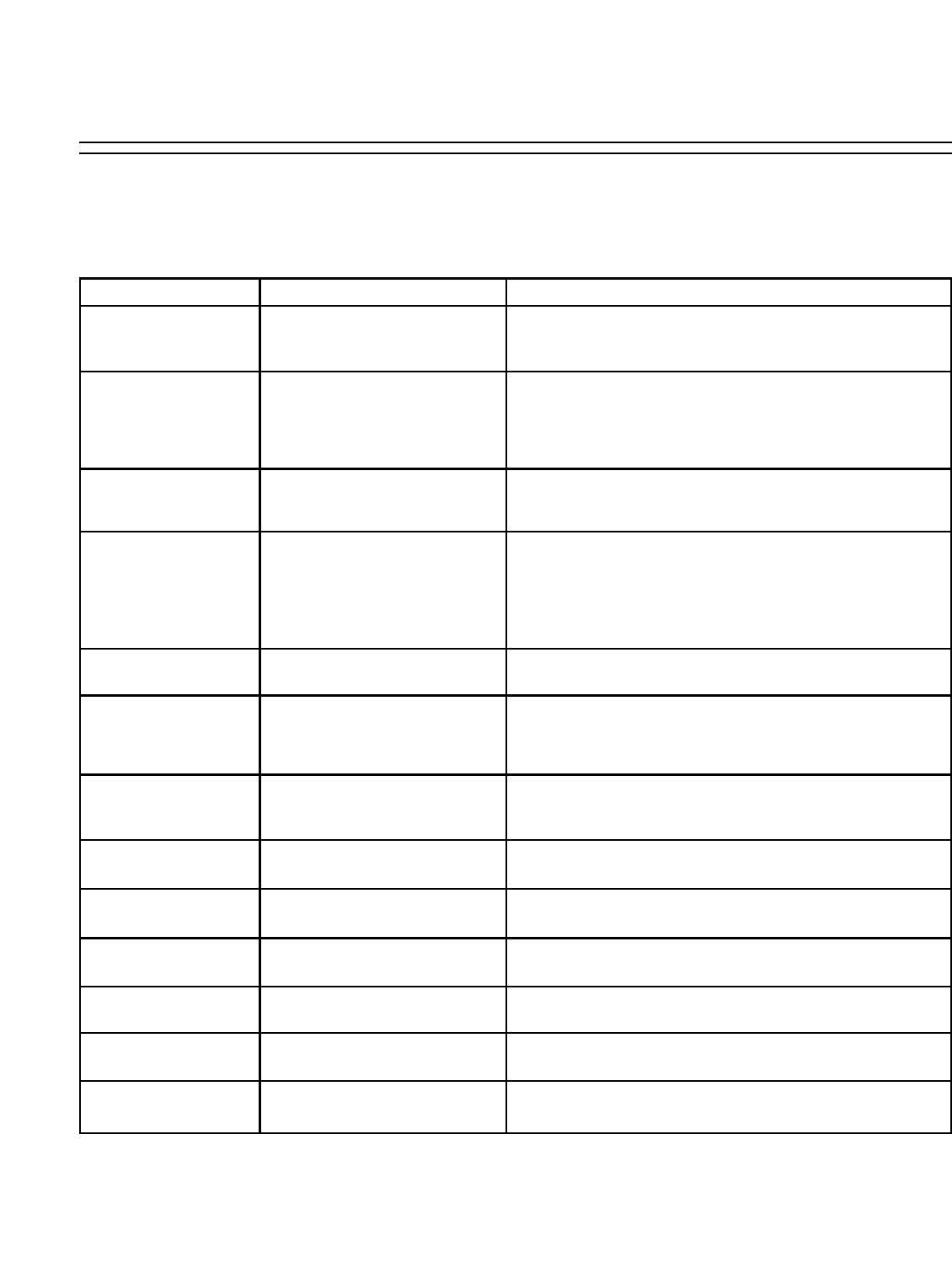

TROUBLESHOOTING

SYMPTOM

Motor will not start.

Motor will not start; fuses or

circuit breakers blow.

Motor overheats.

Motor stalls (resulting in

blown fuses or tripped cir-

cuit).

Machine slows when oper-

ating.

Loud, repetitious noise com-

ing from machine

Machine is loud when cut-

ting. Overheats or bogs

down in the cut.

Infeed roller marks are left

on the workpiece.

Outfeed roller marks are left

on right side of workpiece.

Cannot control snipe.

Chip buildup on outfeed

roller.

Machine howls on startup.

Table moves down while

cutting.

POSSIBLE CAUSE

1. Low voltage.

2. Open circuit in motor or loose

connections.

1. Short circuit in line cord or plug.

2. Short circuit in motor or loose

connections.

3. Incorrect fuses or circuit break-

ers in power line.

1. Motor overloaded.

2. Air circulation through the motor

restricted.

1. Short circuit in motor or loose

connections.

2. Low voltage.

3. Incorrect fuses or circuit break-

ers in power line.

4. Motor overloaded.

1. Feed rate too high.

2. Depth of cut too great.

1. Pulley setscrews or keys are

missing or loose.

2. Motor fan is hitting the cover.

3. V-belt is defective

1. Excessive depth of cut.

2. Knives are dull

Depth of cut too shallow.

Too much spring tension on feed

roller.

Long or heavy board sags as it

enters and exits.

Chips working their way back

under the chip deflector.

Chip deflector too close to the

cutterhead.

Knives dull

CORRECTIVE ACTION

1. Check power line for proper voltage.

2. Inspect all lead connections on motor for loose or open connec-

tions.

1. Inspect cord or plug for damaged insulation and shorted wires.

2. Inspect all connections on motor for loose or shorted terminals or

worn insulation.

3. Install correct fuses or circuit breakers.

1. Reduce load on motor.

2. Clean out motor to provide normal air circulation.

1. Inspect connections on motor for loose or shorted terminals or

worn insulation.

2 Correct the low voltage conditions.

3. Install correct fuses or circuit breakers.

4. Reduce load on motor.

1. Feed workpiece slower.

2. Reduce depth of cut.

1. Inspect keys and setscrews. Replace or tighten if necessary.

2. Tighten fan or shim cover.

3. Replace V-belt. See Maintenance.

1. Decrease depth of cut.

2. Sharpen knives.

Increase depth of cut.

Refer to Feed Roller Pressure section for adjustment.

Lift up on unsupported end of board as it enters and exits cutter-

head.

Lay duct tape over the mounting bolts along the outside edge to

seal any possible gaps.

Move back

1

/8" to

1

/4" from the cutterhead.

Replace knives.