-24-

G0636X 17" Ultimate Bandsaw

Bandsaw

Blade

Support

Bearing

Top View

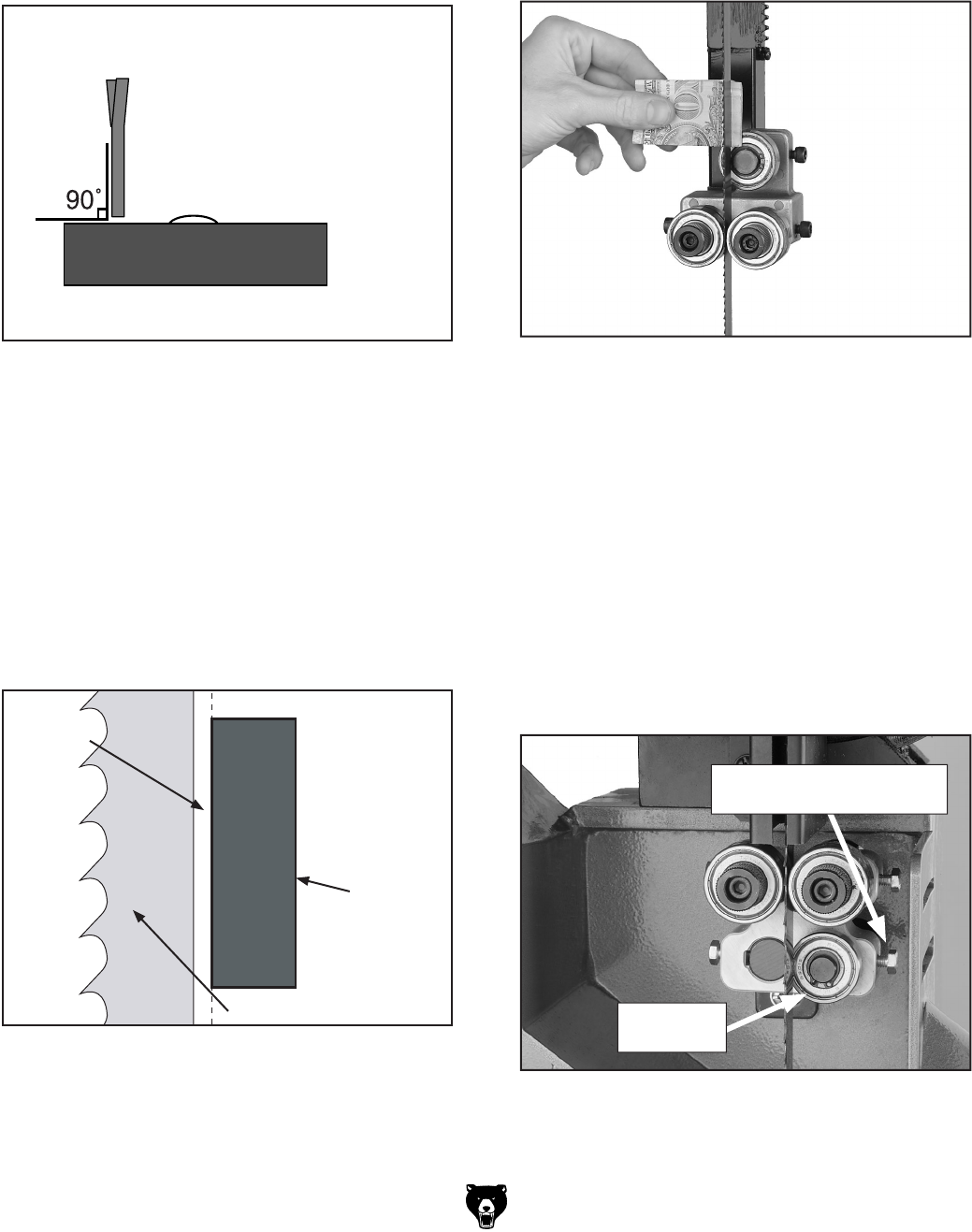

Figure 27. Illustration of blade set perpendicular

(90˚) to the support bearing face.

5. Tighten the guide block assembly cap

screws.

6. Loosen the bolt on the support bearing

adjustment shaft—if it is not already loose.

7. Using a feeler gauge between the support

bearing and the blade, position the bearing

0.016" away from the back of the blade, as

illustrated in

Figure 28.

Figure 28. Blade aligned 0.016" away from the

bearing edge.

Side View

Support

Bearing

Blade

0.016"

Gap

4. Loosen the guide block assembly cap screws

and rotate the blade guide assembly side-to-

side, until the blade is perpendicular with the

face of the support bearing, as illustrated in

Figure 27.

Support Bearing

Blade

Note: For a quick gauge, fold a crisp dollar bill

in half twice (four thicknesses of a dollar bill is

approximately 0.016") and place it between the

support bearing and the blade as shown in Figure

29

.

Figure 29. Example of dollar bill folded twice to

make an approximate 0.016" gauge.

8. Tighten the bolt to keep the support bearing

locked in place.

To adjust the lower support bearing:

1. Make sure the blade is tracking properly and

is correctly tensioned.

2. DISCONNECT BANDSAW FROM POWER!

3. Familiarize yourself with the lower support

bearing controls shown in

Figure 30.

Figure 30. Lower support bearing controls.

Support

Bearing

Support Bearing

Adjustment Shaft Bolt

4. Open the upper and lower wheel covers.