G0636X 17" Ultimate Bandsaw

-25-

5. Make sure that the blade is perpendicular to

the face of the support bearing, as illustrated

in Figure 27.

—If the blade is perpendicular to the face

of the support bearing, continue on to the

next step.

—If the blade is not perpendicular to the sup

-

port bearing, loosen the lateral adjustment

rod cap screw and guide block assembly

cap screws (

Figure 26) and rotate the

assembly side-to-side until it is perpen

-

dicular to the face of the support bearing,

then re-tighten the cap screws.

6. Loosen the bolt on the support bearing

adjustment shaft.

7. Using a feeler gauge, position the bearing

0.016" away from the back of the blade, as

illustrated in

Figure 28, or use a dollar bill, as

shown in Figure 29

.

8. Tighten the bolt to keep the support bearing

locked in place.

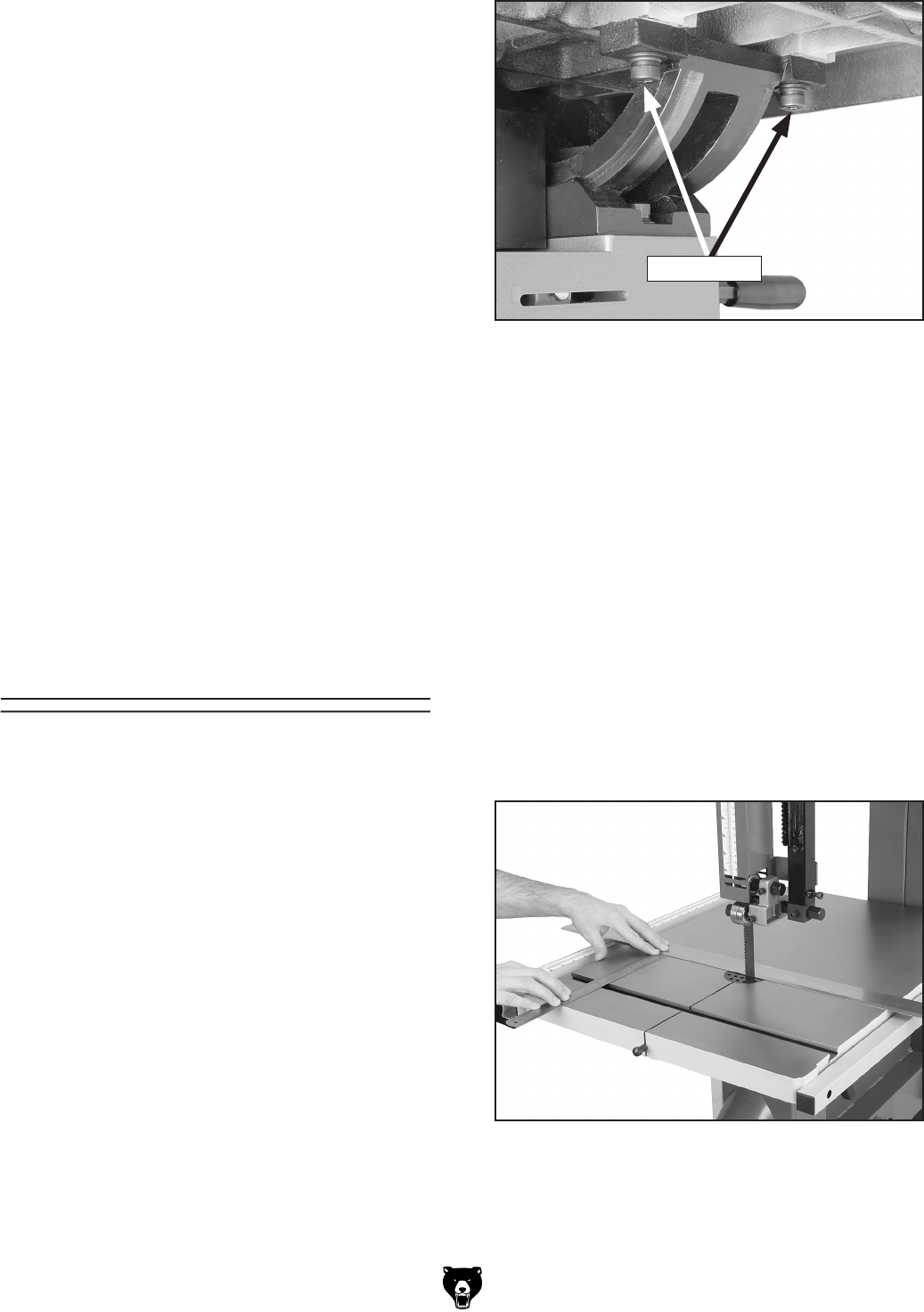

Aligning Table

To ensure cutting accuracy, the table should be

aligned so that the miter slot is parallel to the

bandsaw blade. This procedure works best with a

1

3

⁄8" blade installed.

To align the table so the miter slot is parallel

to the bandsaw blade:

1. Make sure that the blade is tracking properly

and that it is correctly tensioned.

2. DISCONNECT BANDSAW FROM POWER!

3. Loosen the four trunnion cap screws that

secure the table to the trunnions (

Figure

31).

Figure 31. Cap screws securing table to trun-

nion.

4. Place an accurate straightedge along the

blade. The straightedge should lightly touch

both the front and back of the blade.

Note:

Make sure the straightedge does not go

across a tooth.

Figure 32. Example of measuring for miter slot

to be parallel with blade.

5. Use a fine ruler to accurately gauge the dis-

tance between the straightedge and the miter

slot. The distance you measure should be the

same at both the front and the back of the

table (

see Figure 32).

6. Adjust the table as needed for proper align-

ment.

7. Tighten the trunnion cap screws when the

alignment is correct.

Cap Screws