-42-

G0636X 17" Ultimate Bandsaw

Review the troubleshooting and procedures in this section to fix or adjust your machine if a problem devel-

ops. If you need replacement parts or you are unsure of your repair skills, then feel free to call our Technical

Support at (570) 546-9663.

SECTION 7: SERVICE

Troubleshooting

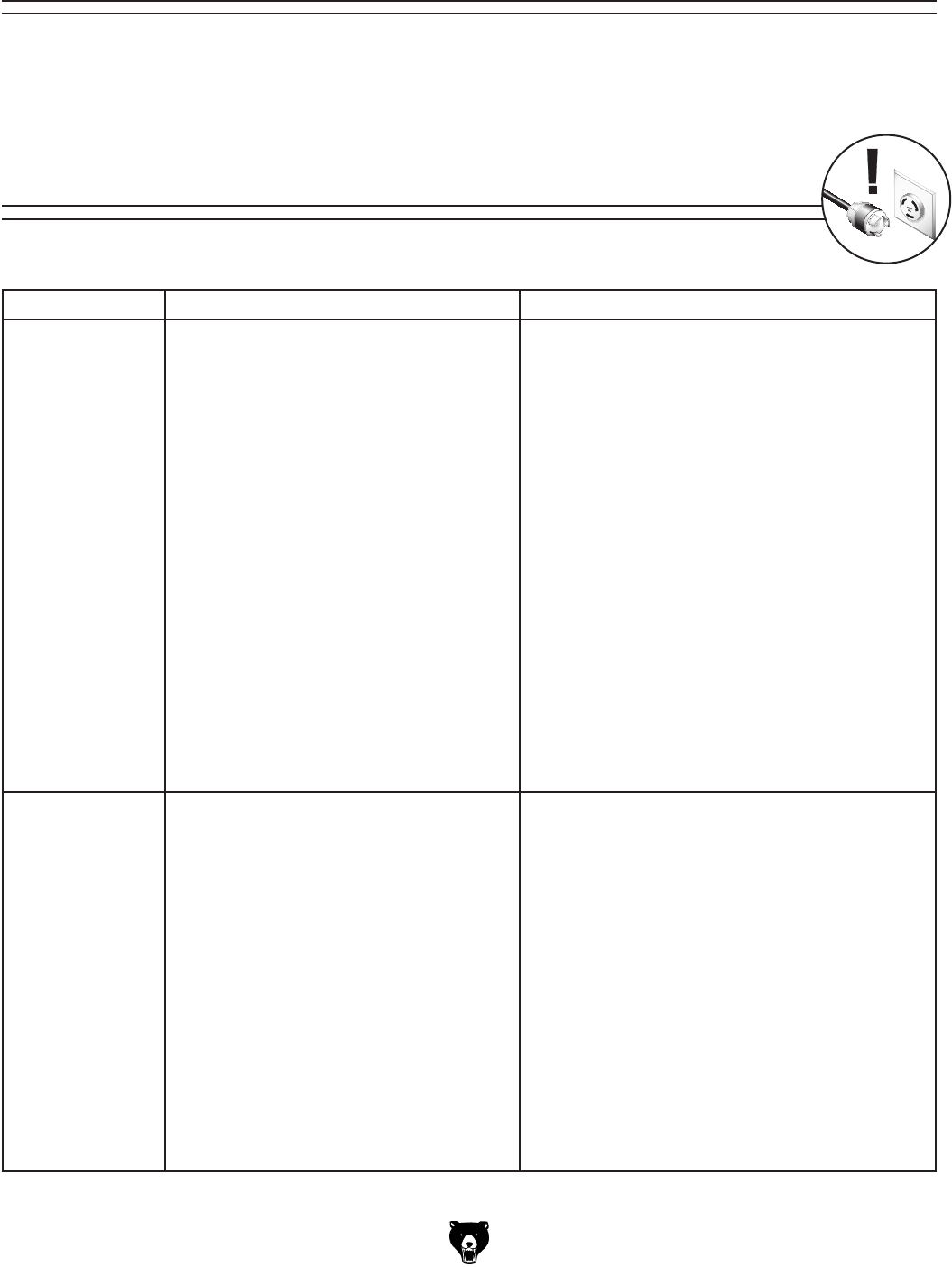

Motor & Electrical

Symptom Possible Cause Possible Solution

Machine does not

start or a breaker

trips.

1. Key is turned to "0".

2. Stop/reset button engaged.

3. Plug/receptacle is at fault or wired incor

-

rectly.

4. Motor connection wired incorrectly.

5. Thermal protection circuit breaker amper

-

age is set too low or motor is at fault.

6. Power supply is at fault/switched OFF.

7. Motor ON/OFF switch is at fault.

8. Wiring is open/has high resistance.

9. Start capacitor is at fault.

10. Motor is at fault.

11. Wheel cover limit switch is not closed,

wheel covers are open.

12. Foot brake limit switch is at fault or is

pressed down (switch is not closed).

1. Turn key to "1".

2. Rotate clockwise until it pops out/replace.

3. Test for good contact or correct the wiring.

4. Correct motor wiring connections (

Page 50).

5. Unplug machine, open magnetic switch cover, turn

amperage dial on Thermal Protection Circuit Breaker

to a higher amperage setting. If switch is maxed out,

replace motor.

6. Ensure hot lines have correct voltage on all legs and

main power supply is switched

ON.

7. Replace faulty ON/OFF switch.

8. Check for broken wires or corroded/disconnected

connections, and repair/replace as necessary.

9. Test/replace if faulty.

10. Repair/replace.

11. Close wheel covers.

12. Repair/replace limit switch, or stop pressing foot

brake.

Machine stalls or is

underpowered.

1. Motor run capacitor at fault.

2. Wrong workpiece material.

3. Feed speed too fast for task.

4. V-belt slipping.

5. Blade is slipping on wheels.

6. Low power supply voltage.

7. Plug/receptacle is at fault.

8. Motor connection is wired incorrectly.

9. Motor bearings are at fault.

10. Motor has overheated.

11. Motor is at fault.

1. Replace run capacitor.

2. Use wood with correct moisture content, without

glues, and little pitch/resins.

3. Decrease feed speed. See Basic Cutting Tips on

Page 28.

4. Replace bad V-belt, align pulleys, and re-tension

(Page 44 & 45).

5. Adjust blade tracking and tension to factory specifi

-

cations. See

Page 16 or 21.

6. Ensure all hot lines have correct voltage on all legs.

7. Test for good contacts and correct wiring.

8. Correct motor wiring connections (

Page 50).

9. Test by rotating shaft; rotational grinding/loose shaft

requires bearing replacement.

10. Let motor cool, clean it off, and reduce workload.

11. Repair/replace.