G0636X 17" Ultimate Bandsaw

-43-

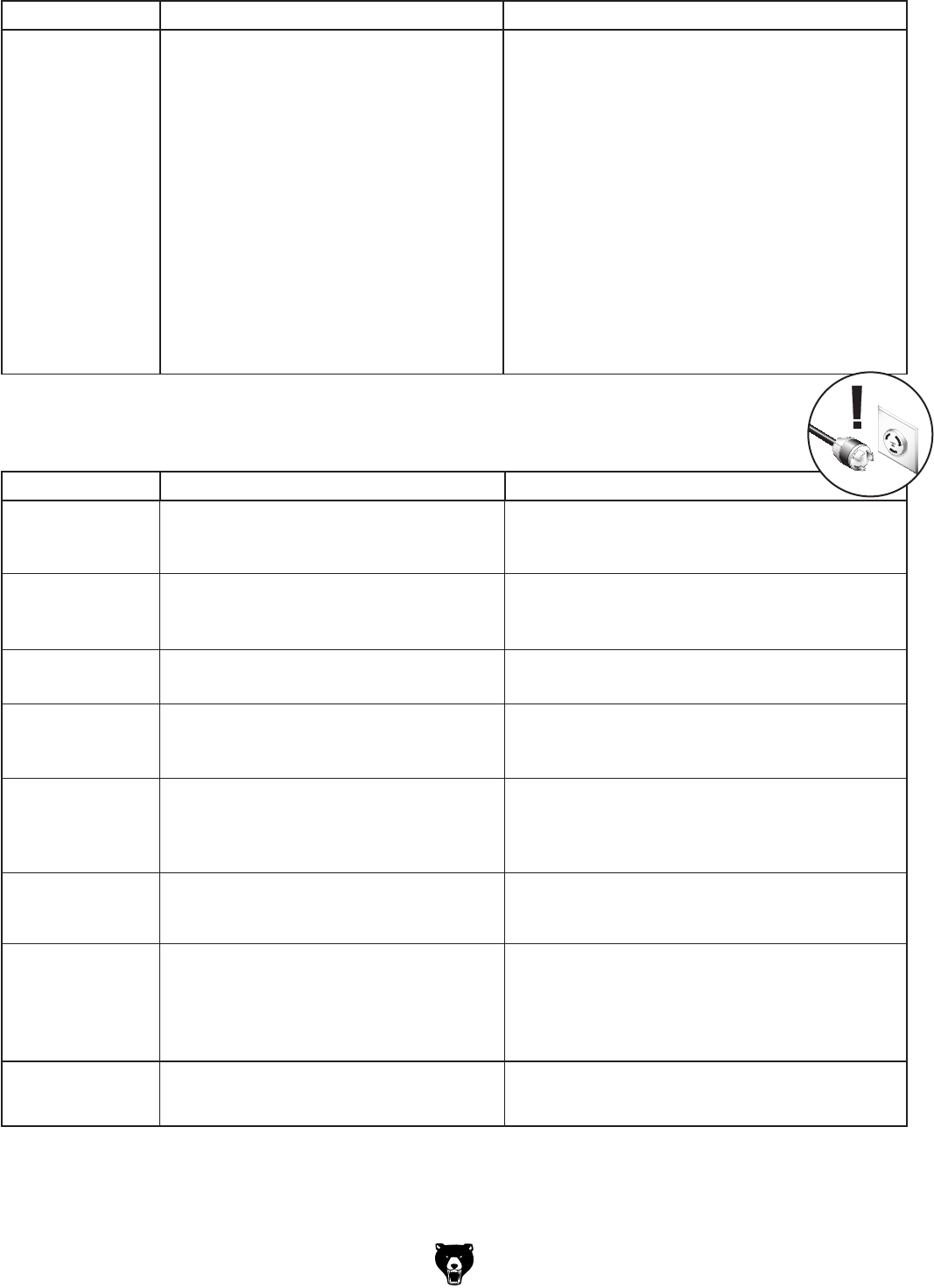

Symptom Possible Cause Possible Solution

Machine slows when

operating.

1. Feeding workpiece too fast.

2. Blade is dull.

1. Reduce feed rate. See Basic Cutting Tips on

Page

28.

2. Replace blade (

Page 36).

Ticking sound when

the saw is running.

1. Blade weld contacting support bearing.

2. Blade weld may be failing.

1. Use file or stone to smooth and round the back of

the blade.

2. Inspect and replace blade if necessary (

Page 36).

Blade contacting

table insert.

1. Excessive side pressure when cutting.

2. Table improperly adjusted.

1. Reduce side pressure.

2. Adjust table (

Page 25).

Vibration when cut-

ting.

1. Loose or damaged blade.

2. Blade is tracking incorrectly.

3. Blade tension is loose.

1. Tighten or replace blade. See

Page 36 or 21.

2. Fix blade tracking (Page 16).

3. Fix blade tension (

Page 21).

Burn marks on the

edge of the cut.

1. Too much side pressure when feeding

workpiece.

2. Blade too wide for size of radius being cut.

1. Feed workpiece straight into the blade. See

Basic

Cutting Tips on

Page 28.

2. Install a smaller width blade/increase blade tension.

See Page 21 or 36.

Rough or poor qual

-

ity cuts.

1. Feeding workpiece too fast.

2. Tracking and tension incorrect.

1. Reduce feed rate. See Basic Cutting Tips on Page

28.

2. Fix tracking and tension (see

Page 16 and 21).

Sawdust buildup

inside cabinet.

1. Clogged dust port.

2. Low CFM (airflow) from dust collection sys

-

tem.

1. Clean out dust port.

2. Three options:

—Check dust lines for leaks or clogs.

—Move dust collector closer to saw.

—Install a stronger dust collector.

Blade wanders or

won't follow line of

cut.

1. Blade lead. 1. Refer to Blade Lead on

Page 30.

Cutting Operations

Symptom Possible Cause Possible Solution

Machine has vibra-

tion or noisy opera

-

tion when running.

1. Blade weld hits guides or teeth are broken.

2. Bent or worn out blade.

3. Motor or component is loose.

4. V-belt worn or loose.

5. Motor fan is rubbing on fan cover.

6. Pulley is loose.

7. Machine is incorrectly mounted or sits

unevenly on floor.

8. Motor bearings are at fault.

9. Worn arbor bearings.

10. Wheels not coplanar/aligned correctly.

11. Wheels out of balance.

1. Replace blade (

Page 36).

2. Replace blade (

Page 36).

3. Inspect/replace stripped or damaged bolts/nuts, and

re-tighten with thread locking fluid.

4. Inspect/replace belts with matched set (

Page 45).

5. Replace dented fan cover and loose/damaged fan.

6. Realign/replace shaft, pulley, setscrew, and key as

required.

7. Adjust the feet on the bottom of the stand; relocate

machine.

8. Test by rotating shaft—rotational grinding/loose shaft

requires bearing replacement.

9. Check/replace arbor bearings.

10. Adjust wheel alignment to coplaner (

Page 46).

11. Replace wheels.