G0449/G0450 37" Drum Sander

-35-

13. Tighten all the lock nuts.

14. Check the height of the drum ends to make

sure they did not move.

—If they did not move, continue to the next

step.

—If they did move, repeat Steps 11-12.

15. Raise the table up until the gauge blocks just

touch the rear drum, as described in Step 7

.

16. Adjust the height of the front drum ends by

loosening the locknuts and sliding the pillow

bearing up or down along the wedge until the

largest size feeler gauge you can fit between

the front drum and gauge blocks at both ends

is 0.015". This will reflect the rear drum depth

of cut.

Note: The 0.015" setting is based off the

suggested depth of cut in the

SECTION

4: OPERATIONS; however, you can set

the front drum between 0.005" and 0.025",

depending on the sandpaper grit size you will

use (ie, coarse grit = larger number; fine grit

= smaller number).

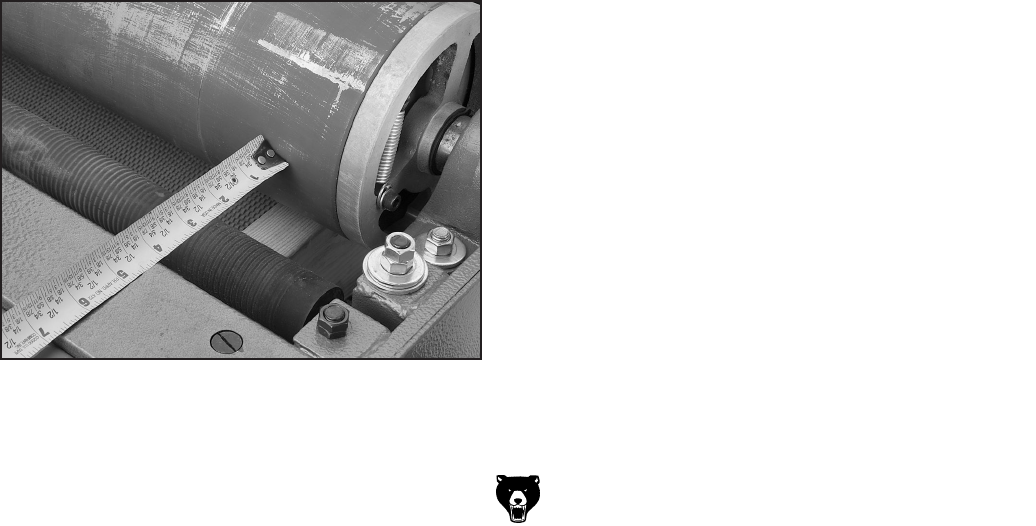

17. At both ends, measure the distance between

the edge of the front drum and the front upper

frame, as shown in

Figure 38. The difference

between these two measurements will tell

you how close the drum is to being perpen

-

dicular to the feed direction.

Figure 38. Measuring distance between edge of

the front drum and the front upper frame angle.

—If the difference between the two measure

-

ments at each end are within

1

⁄8", skip to

Step 19

.

—If the difference between the two measure

-

ments at each end is more than

1

⁄8", con-

tinue to the next step.

18. Go to the end of the drum that has the great-

est distance between the rear upper frame,

and adjust the wedge bolt counterclockwise

until the distance between the upper frame

angle is within

1

⁄8" of the other end.

19. Tighten all the lock nuts.

20. Check the height of the drum ends to make

sure they did not move.

—If they did not move, you have successfully

adjusted the drums. Congratulations!

—If they did move, repeat Steps 17-18.

21. Calibrate the scale pointer as described on

Page 37.