-30-

G0592 Metal Cutting Bandsaw

Always disconnect power

to the machine before

performing maintenance.

Failure to do this may

result in serious person

-

al injury.

SECTION 6: MAINTENANCE

Lubrication

Cleaning the Model G0592 is relatively easy.

After using your bandsaw, remove excess chips

by using the spray gun and by sweeping. Then

remove chips for recycling.

Cleaning

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily Check

:

• Loose mounting bolts.

• Damaged saw blade.

• Worn or damaged wires.

• Any other unsafe condition.

• Clean after each use.

• Proper blade tension.

• Coolant level.

Monthly Check:

• Lubricate vise screw.

• Check gear box fluid level.

Annual Check:

• Change gear box oil (every four months if

being used daily).

Schedule

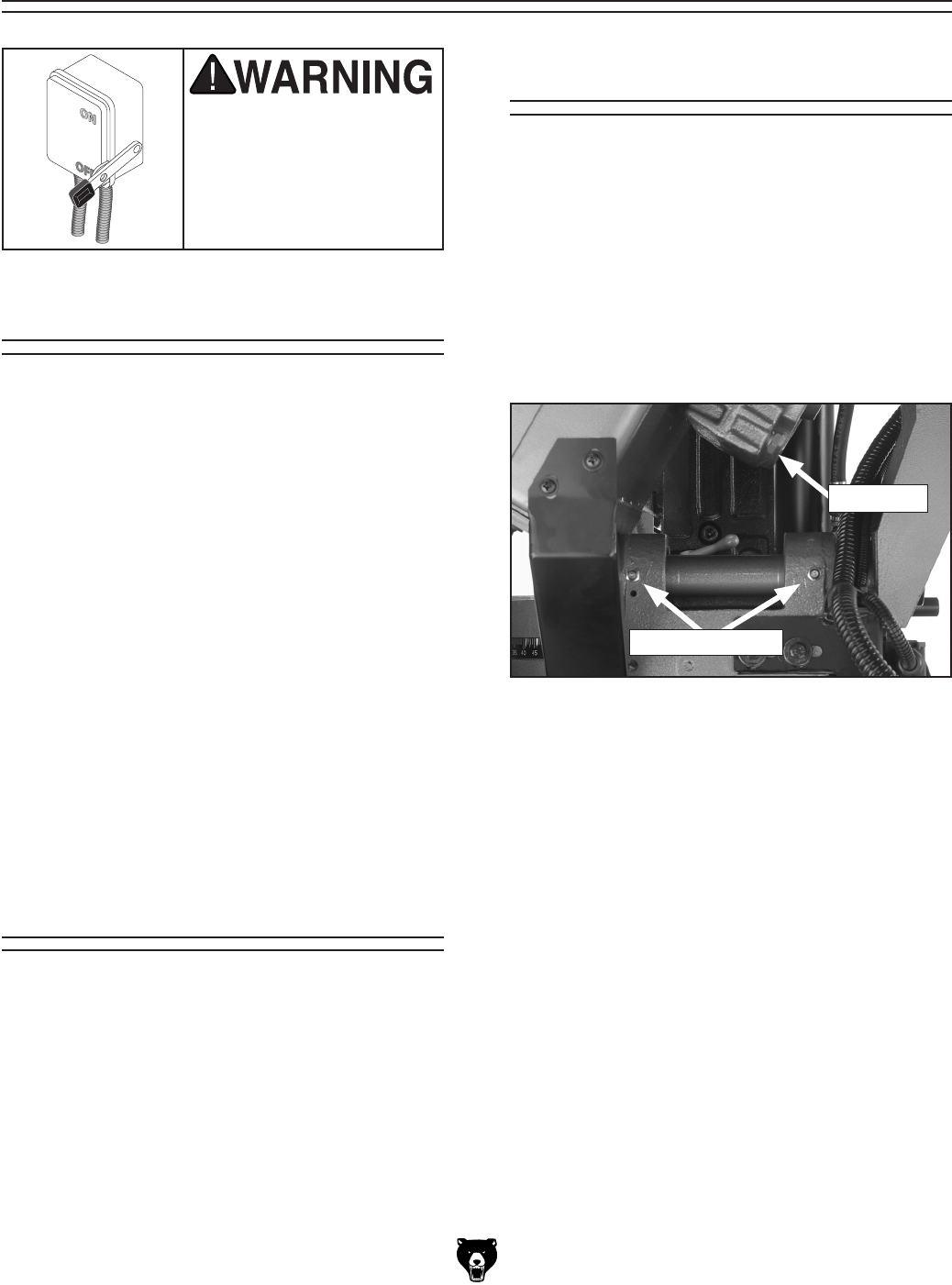

Before applying lubricant to any area, wipe the

area clean to avoid contamination.

Lubricate the

vise leadscrew and the grease fittings at the pivot

point shown in Figure 38 with general purpose

grease.

All bearings on the Model G0592 are lubricated

and sealed for the life of the bearing. No further

attention is needed until it is time to replace the

bearing.

Figure 38. Lubrication points.

The gearbox should be drained and refilled after

the first 50 hours of use and then once every

four months. Use a high quality, ISO 680 grade

synthetic gear oil.

To change the gear oil:

1. Run the bandsaw for ten minutes to warm up

the oil in the gearbox.

2. DISCONNECT THE BANDSAW FROM THE

POWER SOURCE!

3. Raise the bow to the highest angle and close

the feed control knob to lock the bow in posi-

tion.

4. Drain the gearbox by removing the drain plug

shown in

Figure 38.

Drain Plug

Grease Fittings