-36-

G0592 Metal Cutting Bandsaw

The blade guide bearings are adjusted at the fac-

tory but may need adjustment depending on the

use of your bandsa

w. Use Figures 46 & 47 to

guide you through the following steps.

Blade Guide

Bearings

To adjust the blade guide bearings:

1. Before making adjustments, make sure the

blade is tensioned and tracking correctly.

2. DISCONNECT THE BANDSAW FROM

POWER!

3. Lower the bow until it makes contact with the

horizontal stop.

4. Remove the blade guides.

5. The back of the blade should make light con-

tact with the backing bearing

.

—If it does not, loosen the two cap screws

shown in

Figure 46. Lower the blade guide

until the back of the blade makes light con

-

tact with the backing bearing. Then tighten

the two cap screws.

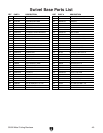

Figure 46. Blade guide adjustments.

Hex Nut

Backing Bearing

Eccentric Bushing

Carbide Blade Guide

Guide Bearings

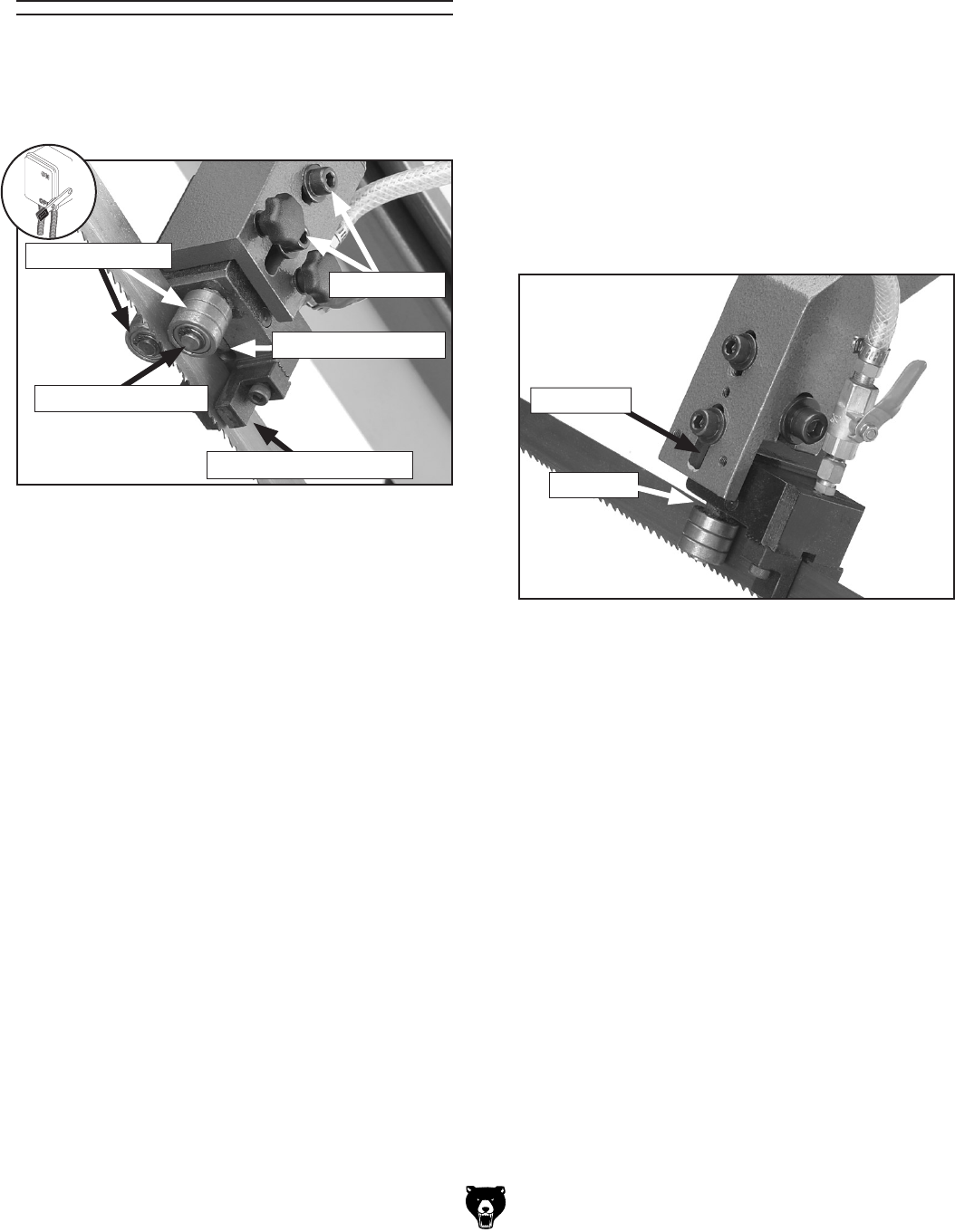

6. Loosen the set screw in Figure 47 to allow

the eccentric bushing to turn.

7. Turn the hex nut on the eccentric shaft to

adjust the distance of the guide be

aring. The

guide bearings and blade should make light

contact or have a maximum clearance of

0.002".

8. Adjust the other eccentric blade guide bear-

ing in the same manner.

9. Adjust the carbide blade guides so they make

the same contact with the blade as the bear

-

ings.

Set Screw

Cap Screws

Figure 47. More blade guide adjustments.