G0605X/G0606X Extreme Series 12" Table Saw

-55-

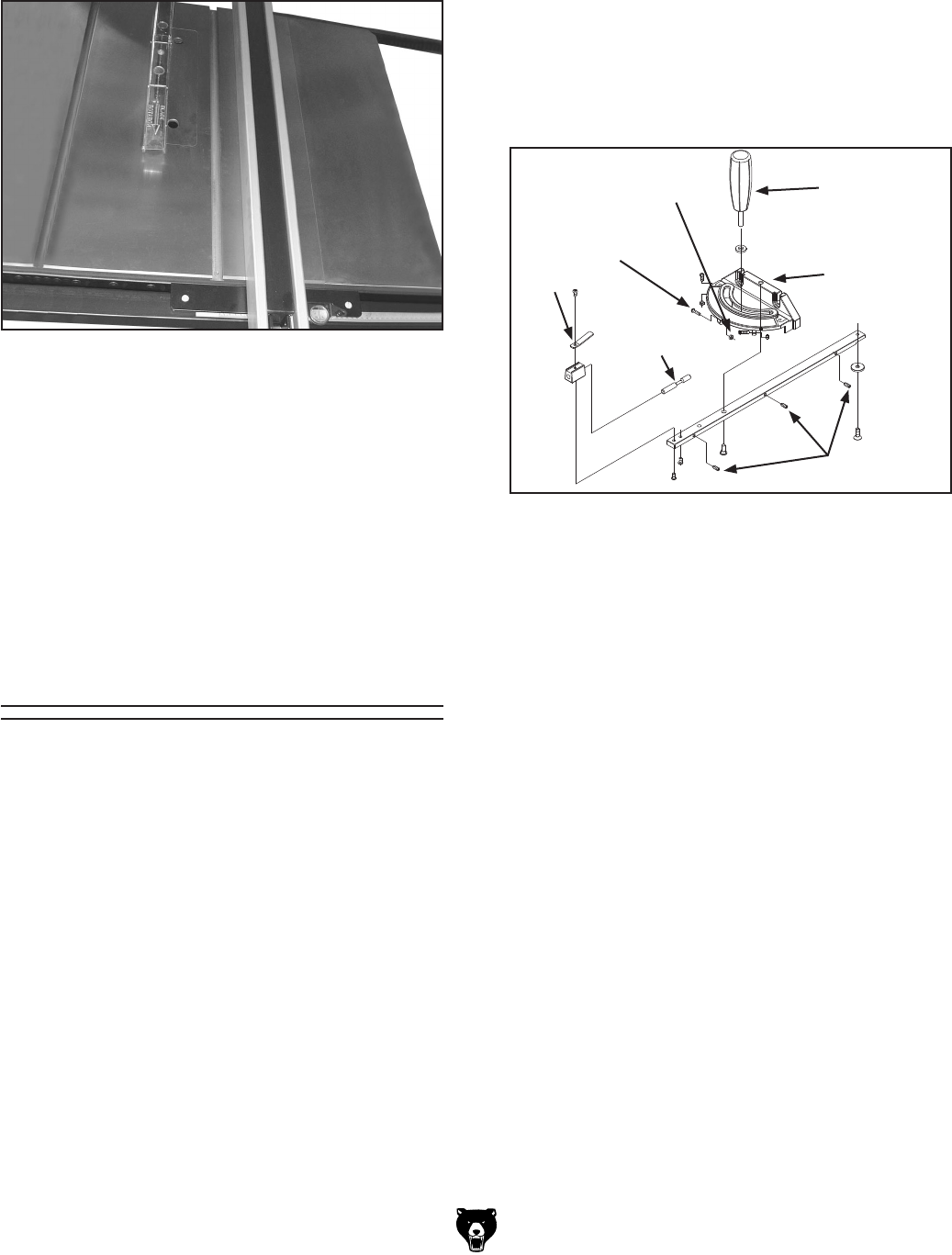

Miter Gauge

Tools Needed Qty

Hex Wrench 2.5mm ...........................................

1

Phillips Head Screwdriver .................................

1

Machinist Square ...............................................

1

Adjustable Square .............................................

1

Wrench 8mm .....................................................

1

To adjust the miter gauge so it is perpendicu

-

lar to the saw blade:

1. Slide the miter gauge into the miter gauge

slot to the left of the blade.

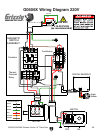

Figure 82. Example of fence aligned parallel to

miter slot.

5. Loosen the jam nut and adjust the stop screw

until it is seated against the shaft (see

Figure

83 for part locations), then tighten the jam

nut.

6 Loosen the screw on the front of the miter

bar, adjust the pointer to 0°, then tighten the

screw.

7. To adjust to 45°, follow Steps 1-5 using an

adjustable square set to 45°.

8. Double-check your adjustments at 45° and

90° to assure that you have accurately set

your miter gauge.

9. To fit the miter bar tighter in the miter slot,

turn the adjustment set screws shown in

Figure 83 clockwise in small increments, and

test fit between adjustments until the miter

gauge fits your expectations.

Figure 83. Miter gauge diagram.

Pointer

Jam Nut

Stop Screw

Shaft

Set

Screws

2. Push in the shaft (Figure 83).

3. Loosen the lock knob on the miter gauge and

place a square against the face of the miter

body and the blade.

4. Adjust the miter body until the pointer is at

0° and there is no space between the square

and the blade, then tighten the lock knob.

Lock Knob

Miter Body

Place the fence alongside the miter slot (Figure

82) and check the fence to miter slot parallelism

and the clamping strength.

Trial-and-error will be needed to adjust the set

screws so the fence is parallel to the miter slot

and the clamping pressure is sufficient.

Optional: If you are cutting wet or green stock,

offsetting the rear of the fence

1

/64" from the blade

using the set screws in Figure

81 can help pre-

vent the workpiece from binding and burning.