-26-

G0619 DELUXE SMALL MILL/DRILL

Review the troubleshooting and procedures in this section to fix your machine if a problem develops. If you

need replacement parts or you are unsure of your repair skills, then feel free to call our Technical Support

at (570) 546-9663.

SECTION 7: SERVICE

About Service

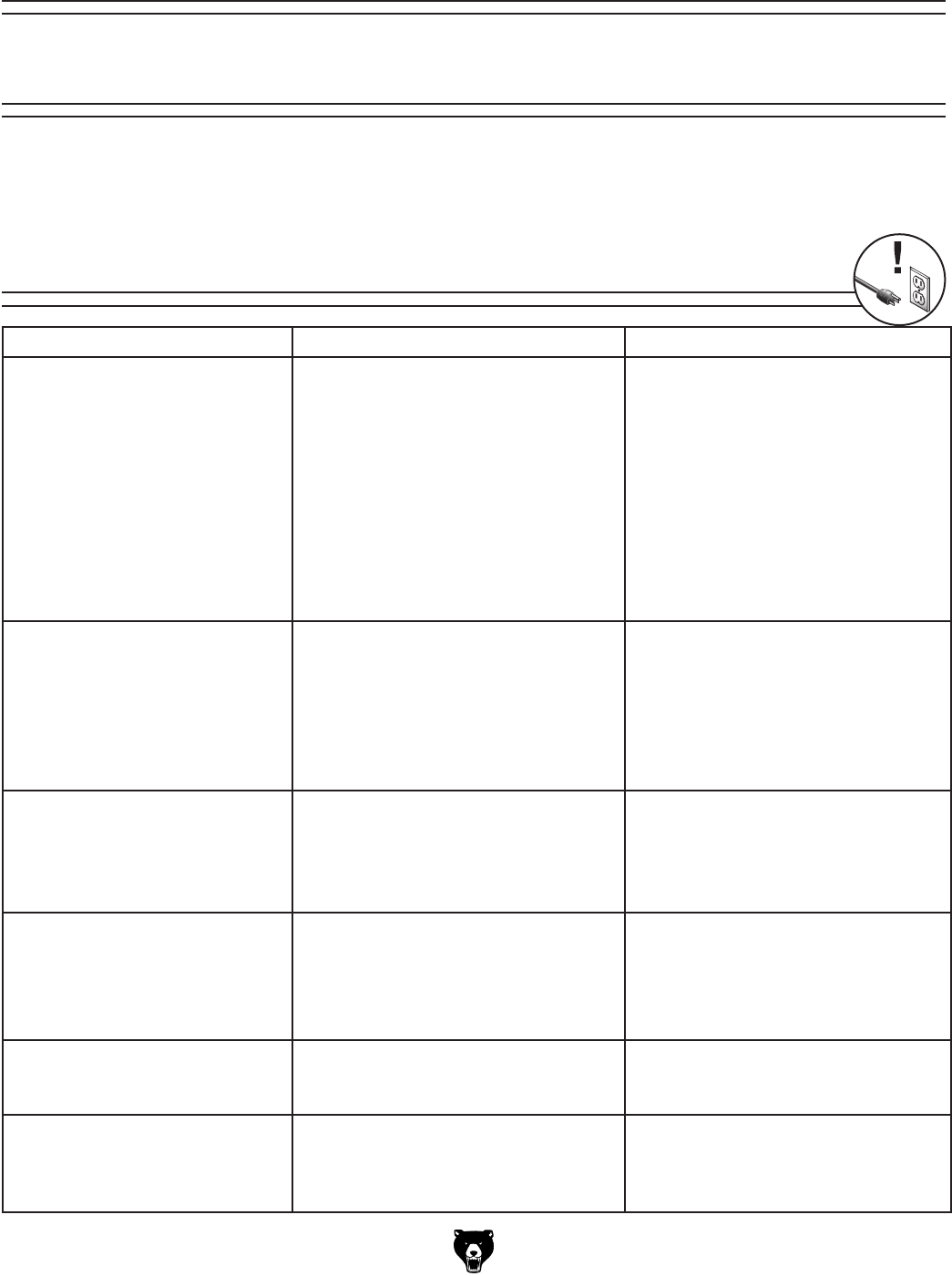

Symptom Possible Cause Possible Solution

Motor will not start.

1. Emergency stop button is pressed.

2. Chip guard switch at fault (Figure 40).

3. Main power switch at fault (

Figure 37).

4. Blown power supply fuse (Figure 37).

5. Blown inverter fuse (Figure 36).

6. Shorted capacitor (Figure 36).

7. Shorted transformer (Figure 36).

8. Open circuit in motor or loose connec

-

tions.

1. Reset switch or replace bad switch.

2. Fully close chip guard, or replace bad

switch.

3. Turn dial on, or replace bad switch.

4. Repair short and replace 20A fuse.

5. Repair short and replace 15A fuse.

6. Replace both capacitors.

7. Replace transformer.

8. Inspect circuit boards, wiring connec

-

tions, plugs, and repair/replace as

required (Page 31).

Feed handle tapping button does not

work.

1. Machine is not in "Tapping Mode."

2. Tapping button slip ring switch is at

fault (Figure 40).

3. General electrical problem.

1. Press the START and then the

TAPPING buttons (Page 20).

2. Replace tapping button slip ring

switch.

3. Inspect circuit boards, wiring connec

-

tions, plugs, and repair/replace as

required (Page 31).

Control panel FORWARD and

REVERSE buttons do not work.

1. Machine is not in "Mill/Drill Mode."

2. General electrical problem.

1. Press the STOP and then the START

buttons (Page 20).

2. Inspect circuit boards, wiring connec

-

tions, plugs, and repair/replace as

required (Page 31).

Poor surface finishes. 1. Feed rate too fast.

2. Dull cutter.

3. Lock not tightened down.

4. Gibs loose.

1. Slow feed rate.

2. Always use newly sharpened cutters.

3. Tighten column and table locks when

possible to maintain rigidity.

4. Adjust gib (Page 27).

Vibration when running or cutting. 1. Feed rate too high.

2. Loose table.

3. Loose gibs.

1. Slow feed rate or adjust RPM.

2. Tighten table locks.

3. Adjust gib (Page 27).

Headstock hard to raise. 1. Headstock lock or gib is at fault.

2. Headstock lead screw is binding.

1. Loosen/replace lock lever and adjust

gib (Page 27).

2. Clean and relubricate headstock

leadscrew and gears (Page 28

).

Troubleshooting