G8621 Heavy-Duty Sliding Table Shaper -19-

Speed Changes

The Model G8621 Shaper is equipped with a V-

belt drive system that controls the speeds. To

change spindle speeds:

1. Unplug the machine.

2. Loosen the two motor plate bolts, and slide

the motor toward the spindle assembly. DO

NOT take the bolts out.

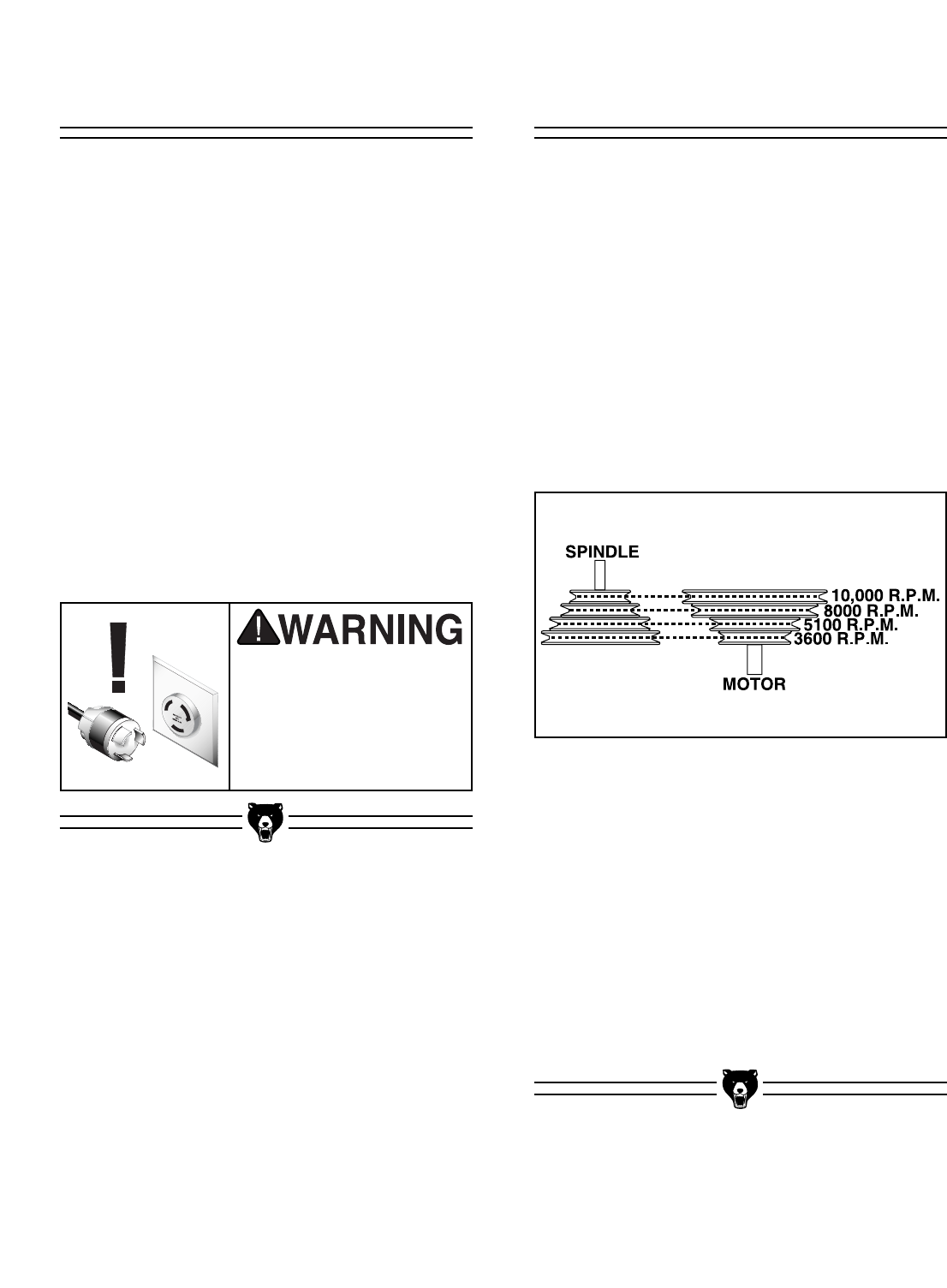

3. Select the desired speed. There are four

speeds: 3600 R.P.M., 5100 R.P.M., 8000

R.P.M., 10,000 R.P.M. Figure 26 shows the

belt positions for each available speed.

4. Align the belt along the appropriate pulley

grooves.

5. Slide the motor back into position and tight-

en the belt. When the belt is properly ten-

sioned, there should be approximately

1

⁄4" of

deflection in the center of the belt when you

press it with moderate pressure.

6. Tighten all the adjusting bolts.

7. Spin the pulley to ensure proper tracking.

V-Belt Tension

You should be able to deflect the belt

1

⁄4" with

moderate finger pressure. This may seem tight

compared to most other V-belts, but since the belt

is small and runs fast, this amount of tension is

necessary. The V-belt will slip if too loose, and

will squeal or cause vibration if too tight. Adjust

the tension if necessary. To adjust V-belt tension:

1. Make sure the pulleys are properly aligned.

2. Loosen the two motor mount plate bolts and

slide the motor left or right to modify the belt

tension. Keep the pulleys aligned.

3. Tighten the motor mount plate bolts, test the

tension, and check the pulleys.

4. Repeat steps 2-3 until tension is correct and

the pulleys are aligned.

Disconnect power to the

machine when perform-

ing any adjustments or

maintenance. Failure to

do this may result in seri-

ous personal injury.

Figure 26. Spindle speed adjustment.