-24- G8621 Heavy-Duty Sliding Table Shaper

Cutter Installation

Your shaper operates at speeds of 3600, 5100,

8000 and 10,000 R.P.M. 3

1

⁄

2

" or larger cutters

must be operated at the slowest speed.

Always use the largest spindle size possible, and

never use more than one bushing size to gain two

spindle sizes. ”Stacking” two cutter bushings to

decrease the inside diameter of the cutter will

cause the cutter to perform incorrectly when

placed under a load.

1. Unplug the shaper.

2. Place an appropriate spacer or collar at the

base of the spindle for support. Place the

cutter on the spindle, making sure the rota-

tion is correct for your application.

3. Use spacers or collars to suit your particular

application, then place the spindle washer

under the nut. Screw on the nut and locknut.

4. Tighten the nuts while holding the spindle

stationary. Use a wrench on the notches at

the top of the spindle for leverage as shown

in Figure 31.

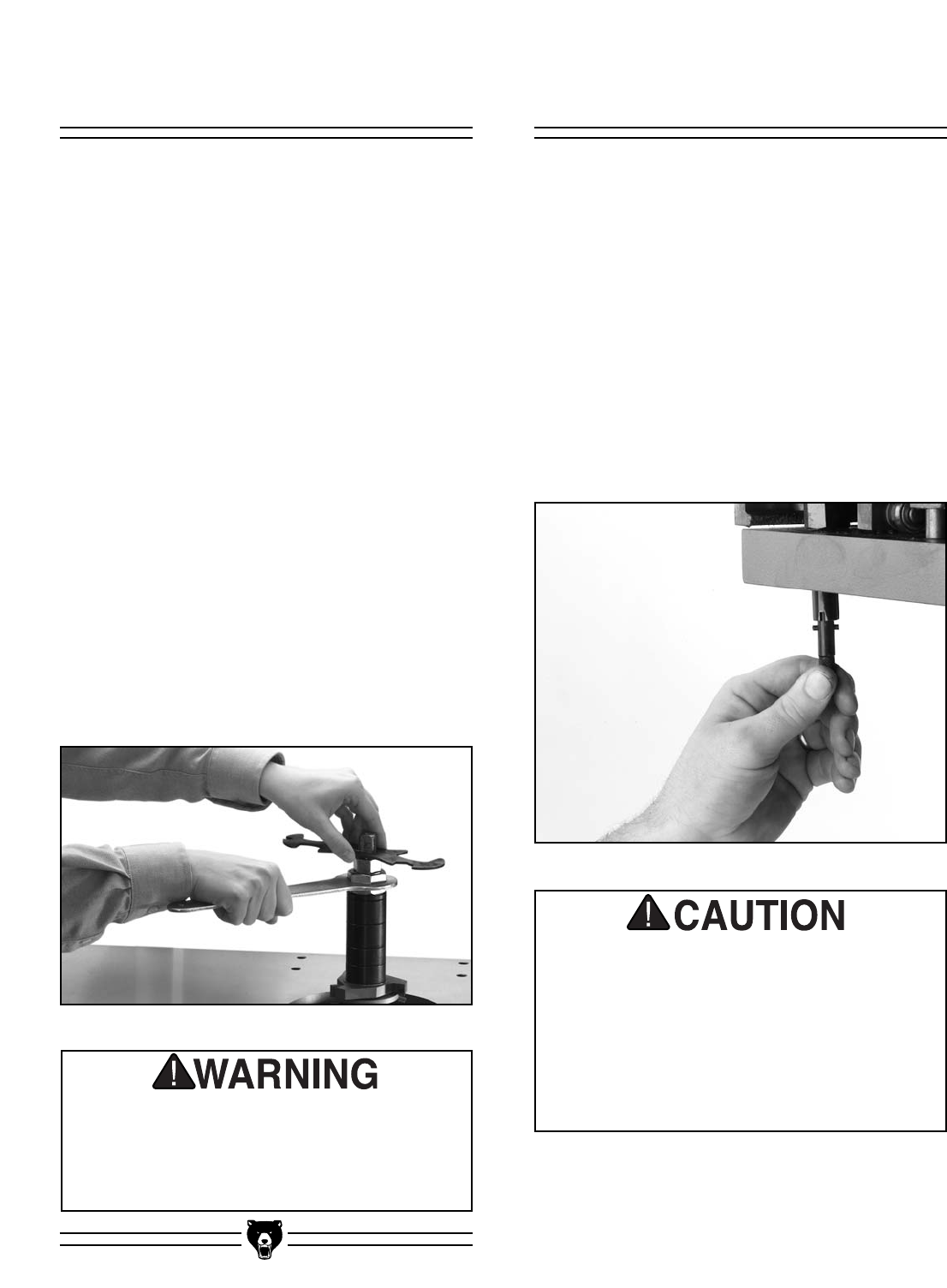

Table Lock

The sliding table works with the clamping miter

gauge to allow you to secure your workpiece to

the table and make the cut by sliding the table.

This feature greatly increases operator safety

because it keeps hands away from the cutter-

head.

When the sliding operation is not desired, the

table lock shown in Figure 32 will make the table

stationary. Simply pull the knurled shaft and twist

it so the cross pins slide into the largest slots in

the housing. If you want to unlock the table, pull

the shaft, twist it, and place the cross pins in the

smallest slot.

Figure 32. Table lock.

The sliding table makes it easy to feed the

work into the cutter at a faster rate than

would normally be used. Always feed the

work slow and steady to avoid kickback

and to achieve smooth results with your

work. Although the miter assembly does

aid in safety, common sense should always

be used during every shaping operation.

Figure 31. Tightening spindle nuts.

Always use a spindle lock nut during oper-

ation. If this warning is ignored, the cutter

may fly off the spindle during use and

cause severe personal injury.