G8621 Heavy-Duty Sliding Table Shaper -21-

Table Inserts

The Model G8621 is supplied with two inserts

which provide three possible opening diameters

in the shaper table surface. Use the smallest

opening that a particular cutter will allow. This

offers more support for the workpiece and

reduces the amount of chips that can fall into the

machine. The correct spindle opening also allows

any unused portion of the cutter to remain below

the table surface—increasing operator protection.

The cast iron table insert must be flush with the

top of the table. To adjust the insert:

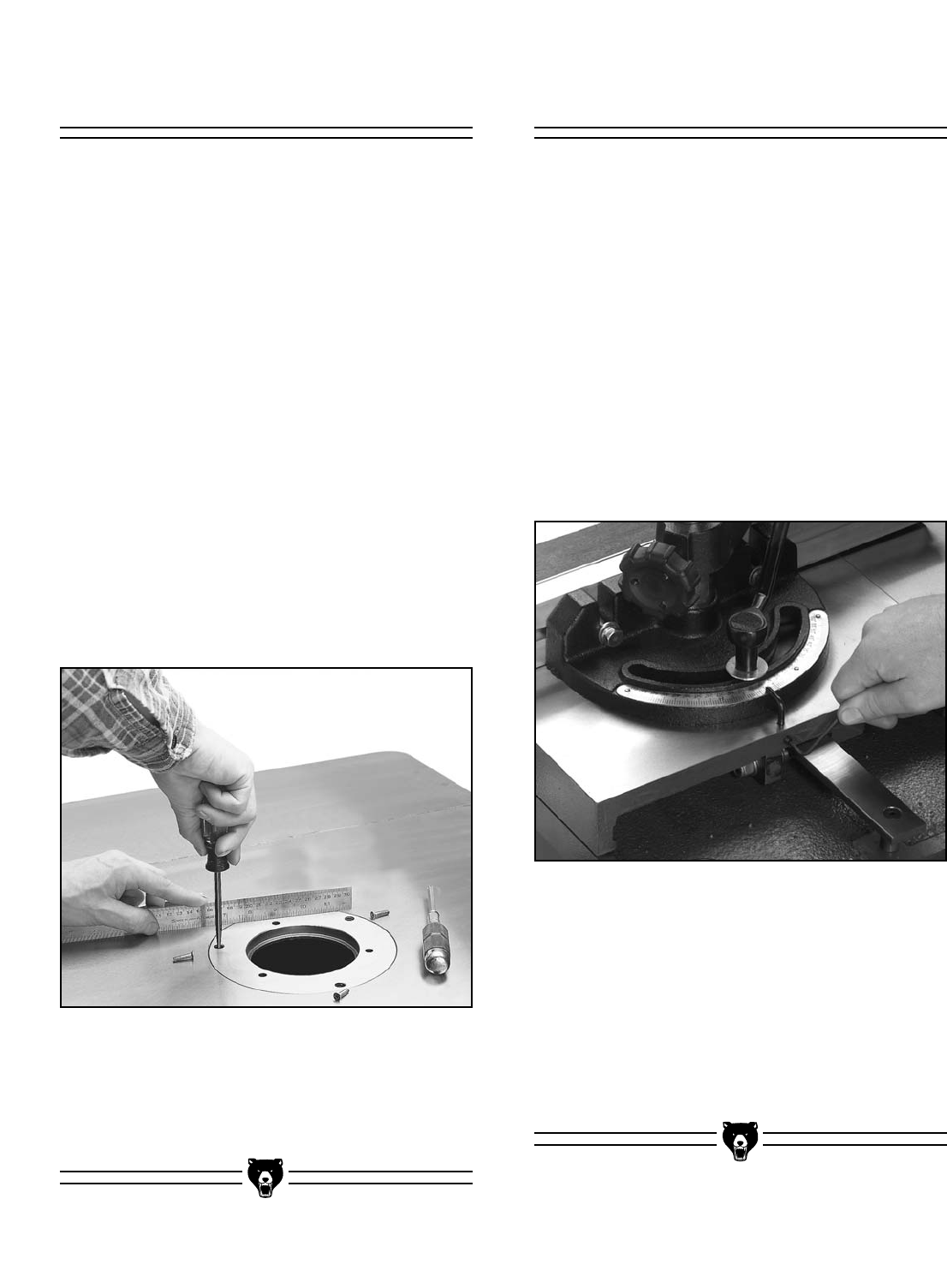

1. Remove the three Phillips

®

head screws that

hold the cast iron insert in place.

2. By using a straightedge and a screwdriver,

turn the barrel screws clockwise or counter-

clockwise to level the cast iron insert with the

table. See Figure 28.

3. Inspect with the straightedge from both side-

to-side and front-to-back to ensure the insert

is flush with the table. Replace and secure

the Phillips

®

head screws.

Figure 28. Leveling table insert.

Figure 29. Setting the miter gauge pointer.

Setting Miter Gauge

It is necessary to square the miter gauge each

time it is removed from the table. To do this:

1. Ensure that the fence halves are aligned and

that the miter assembly is correctly assem-

bled.

2. Place one end of a framing or try square

flush with the infeed shaper fence.

3. Rotate the miter gauge so that it lines up

flush with the other end of the square.

4. Set the miter gauge pointer to 0° and tighten

the setscrew as shown in Figure 29.

5. Keeping the square flush with the infeed

fence and the miter fence, clamp it to the

table, and slide the table across the shaper.

The square should stay flush with both

infeed and outfeed fences during this move-

ment. If this is the case, proceed to the next

section. If they do not stay flush or are not

square to the miter fence, repeat steps 1-4

until they are true.