G8621 Heavy-Duty Sliding Table Shaper -23-

SECTION 6: OPERATIONS

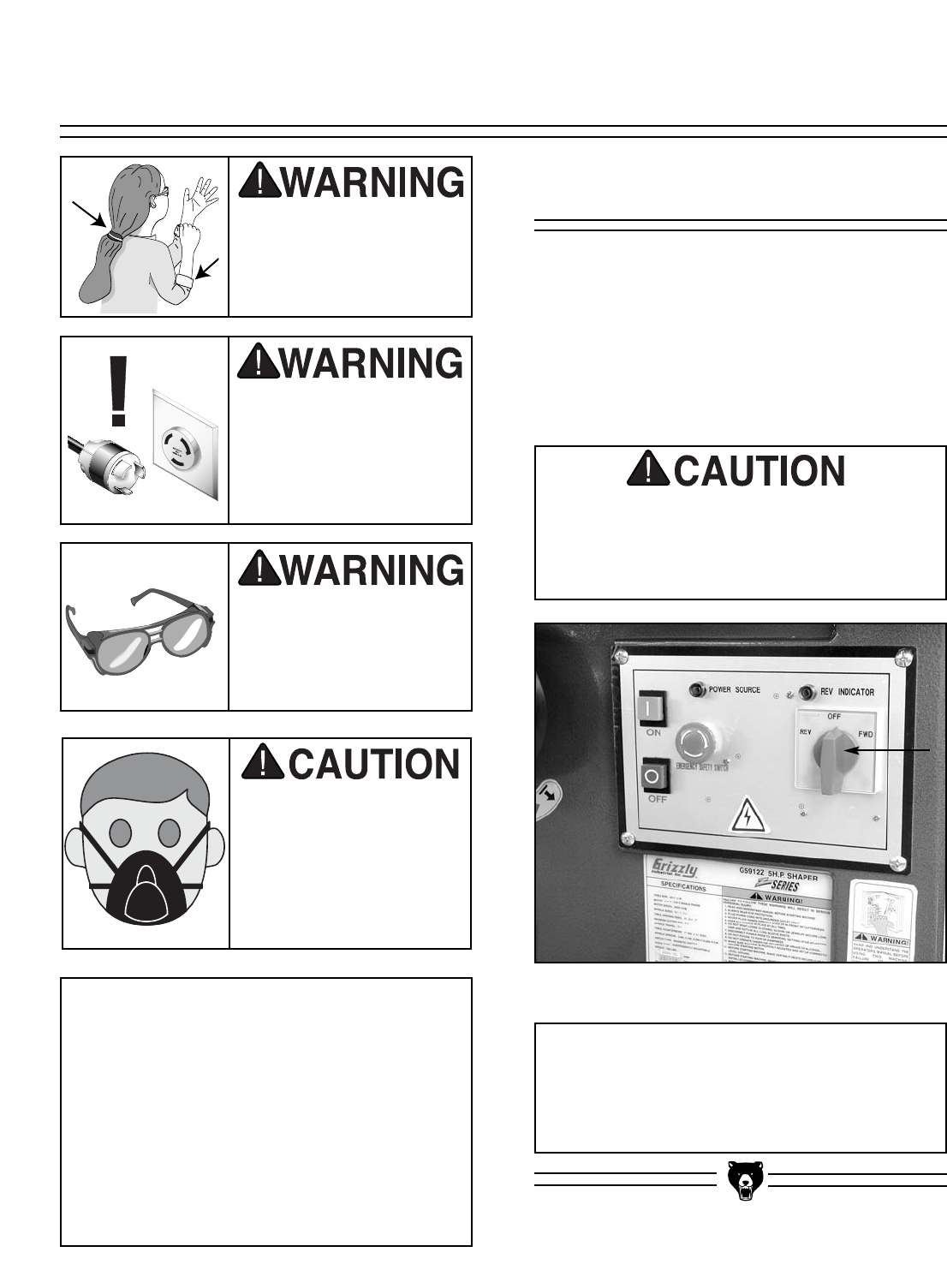

Figure 30. FORWARD/REVERSE switch.

Rotation

Your shaper is equipped with a

FORWARD/REVERSE switch as shown in

Figure 30. In many instances, you will need to flip

the cutter over and reverse cutter rotation.

Whenever possible, mount the cutter so the

board is milled on the bottom side. This method

does a better job and is safer for the operator.

Always check the direction of cutter rota-

tion before beginning any shaping opera-

tion, and always feed the work against the

direction of the cutter rotation.

Keep loose clothing

rolled up and out of the

way of machinery and

keep hair pulled back.

Wear safety glasses dur-

ing all operations on the

shaper. Failure to com-

ply may result in serious

personal injury.

Disconnect power to the

machine when perform-

ing any adjustments or

maintenance. Failure to

do this may result in seri-

ous personal injury.

Always wear a dust

mask when operating

the shaper. Using this

machine produces saw-

dust which may cause

allergic reactions or res-

piratory problems.

NOTICE

This machine was designed to be started

and stopped with the ON/OFF buttons—not

the reversing switch.

NOTICE

The following section was designed to give

instructions on the basic operations of this

shaper. However, it is in no way compre-

hensive of every shaper application. There

are many different jigs that can be built to

increase safety, accuracy, and types of

cuts. WE STRONGLY RECOMMEND that

you read books, trade magazines, or get for-

mal training to maximize the potential of

your shaper.