For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 23SKU 55525

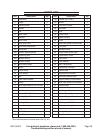

Crooked/wavy bead

POSSIBLE CAUSES AND SOLUTIONS

Stickout too long:

Reduce stickout.

Inaccurate welding:

Use two hands or rest hand on steady

surface.

1.

2.

TOP

VIEW

Porosity

Small cavities or holes in the bead.

POSSIBLE CAUSES AND SOLUTIONS

Stickout too long:

Reduce stickout.

Dirty workpiece or welding wire:

Make certain that workpiece and wire are

both clean and free from oil, coatings, and

other residues.

Insufficient gas flow at weld:

Increase flow of shielding gas.

Dirty nozzle:

Clean nozzle by following the directions in

the cleaning section of this manual.

Wrong type of shielding gas:

Use only the correct welding gas for the

application and wire.

1.

2.

3.

4.

5.

TOP

VIEW

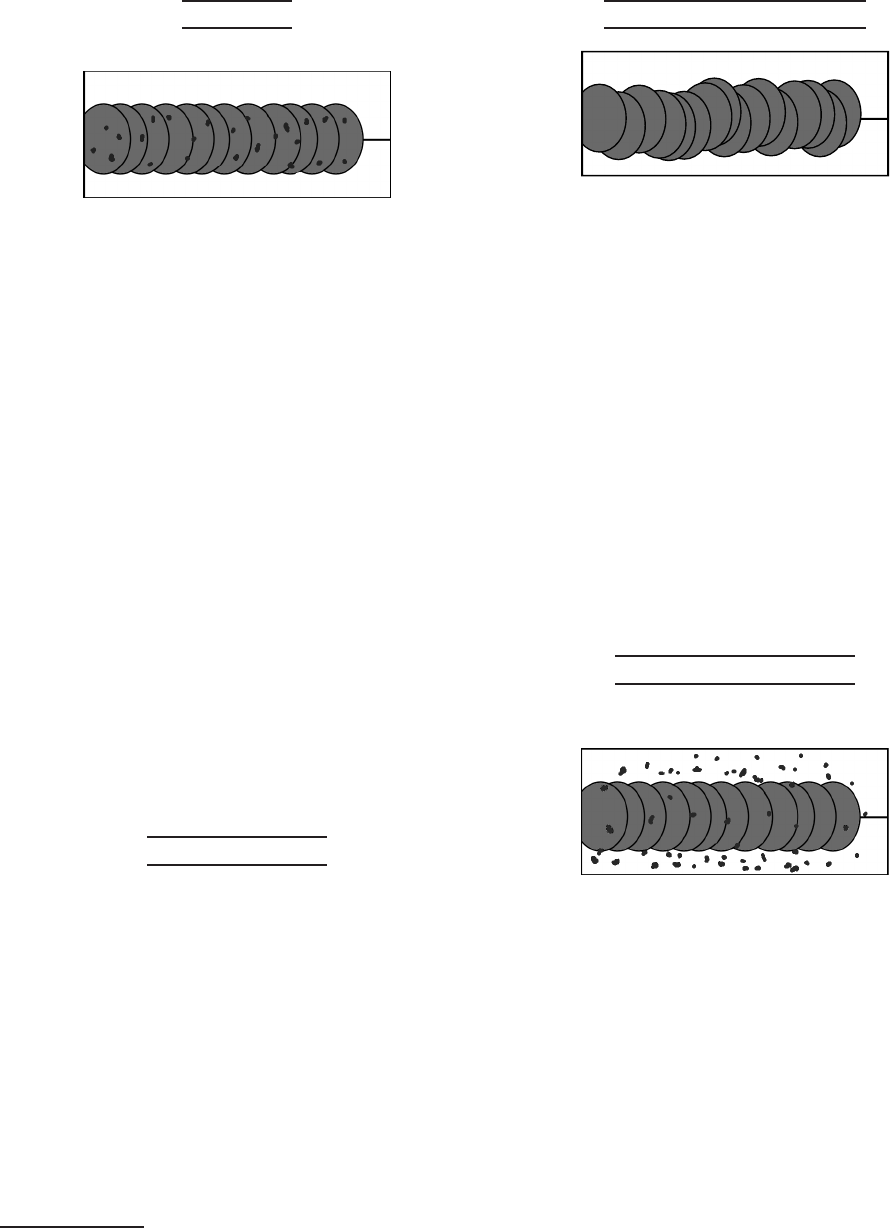

Excessive Spatter

Spatter that is grainy and large.

Fine spatter is normal.

POSSIBLE CAUSES AND SOLUTIONS

Wire feeding too fast:

Reduce wire feed speed.

Stickout too long:

Reduce stickout.

Dirty workpiece or welding wire:

Make certain that workpiece and wire are

both clean and free from oil, coatings, and

other residues.

Insufficient gas flow at weld:

Increase flow of shielding gas.

Shielding gas being blown away from

weld area:

Protect the weld area from drafts.

1.

2.

3.

4.

5.

TOP

VIEW

STRIKE TEST

A test weld on a PIECE OF SCRAP can be tested

by using the following procedure.

W EA R AN S I G OG G LE S D UR I NG T HI S

PROCEDURE.

After two scraps have been welded to-

gether and the weld has cooled, clamp one

scrap

*

in a sturdy vise.

Stay clear from underneath while you strike

the opposite scrap with a heavy hammer,

preferably a dead-blow hammer.

A good weld will deform but not break.

A poor weld will be brittle and snap at the

weld.

* This test WILL damage the weld it is performed

on. This test is ONLY an indicator of weld tech-

nique and is not intended to test working welds.

1.

2.

3.