OM-1594 Page 32

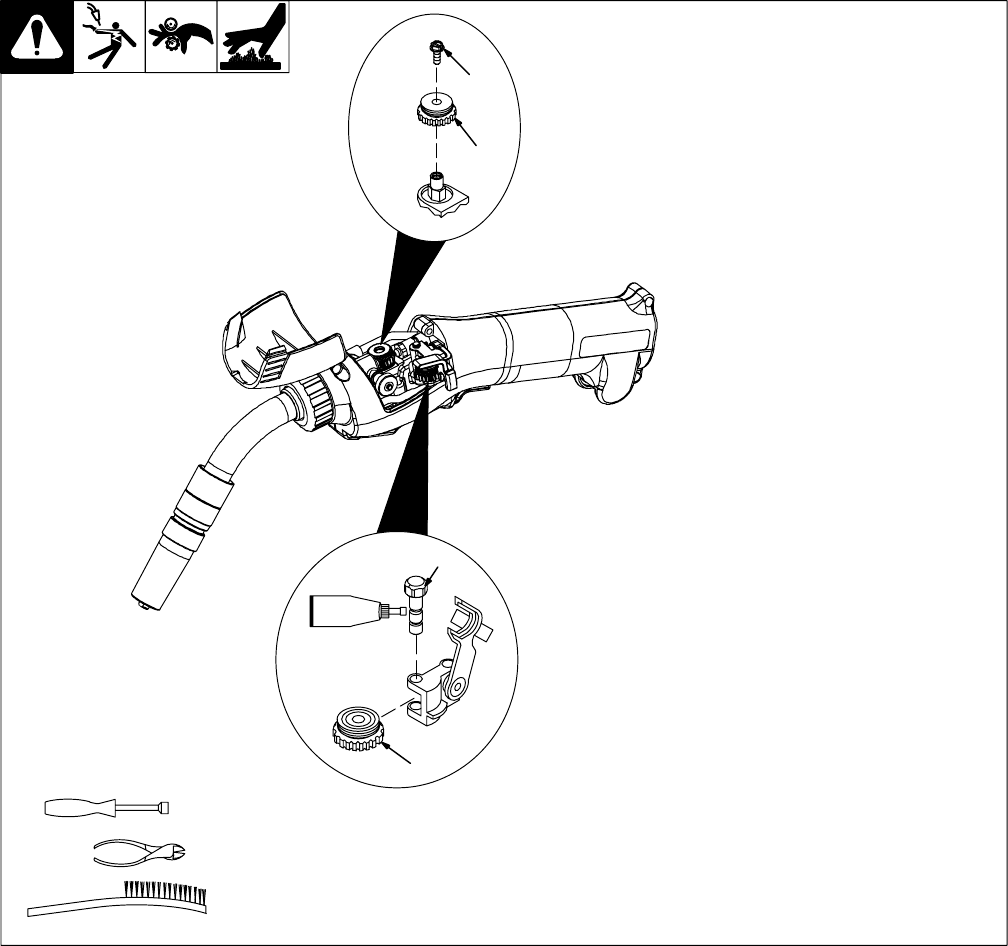

6-2. Gun Drive Assembly Maintenance For An XR-Edge Gun

Ref. 801 556

Retract wire onto spool.

1 Screw

2 Drive Roll

Use wire brush to clean drive roll.

Install drive roll with hex opening

down toward shaft hex, and secure

with screw.

. Apply conductive grease to

drive roll post every 4 to 6

weeks.

3 Post

4 Pressure Roll w/Bearing

Use wire brush to clean pressure

roll. Install pressure roll so that gear

teeth mesh with drive roll gear

teeth, and secure with screw.

If changing drive roll in feeder, see

Section 6-1.

Thread welding wire through gun.

Close and secure pressure roll

assembly. Adjust drive roll

pressure, if necessary (see Section

4-13).

Drive roll and pressure roll are

available for the following wire

sizes:

.030 wire size

.035 wire size

.047 wire size

.062 wire size

When changing wire size, change

control box drive roll and idler (see

Section 6-1), gun pressure roll and

drive roll, and gun liner (see Section

6-4 and 6-9).

Close top cover.

Tools Needed:

5/16 in

1

2

3

4

Conductive

Grease