6

PRESSURE SWITCH ADJUSTMENT

aWARNING High voltage is present at the pressure switch

contacts when the power supply is

connected. Disconnect, lock and tag main

power supply before making adjustments.

aCAUTION Do not adjust the pressure switch to exceed

the maximum discharge pressure of the unit.

NOTE Adjust the pressure switch only if

adjustments are absolutely necessary.

CUT-IN & CUT-OUT. The cut-out (compressor shut-down) is the

pressure at which the switch contacts open, and the cut-in (compressor

restart) is the pressure at which the switch contacts close.

ADJUSTMENT CONTROLS. All pressure switches have a range

adjustment control (A). Some pressure switches also have a differential

adjustment (B) control. On switches without a differential adjustment

control, the span between cut-in and cut-out pressure levels switches

is factory set for 40 ± 4 PSIG and cannot be adjusted.

NOTE Some pressure switches are equipped with

an on-off lever used to open and close the

electrical contacts inside the switch. THIS

LEVER IS NOT A DIFFERENTIAL ADJUSTMENT

CONTROL. The pressure switches with the on-

off lever do not have a differential adjustment

control.

ADJUSTMENT PROCEDURES (SWITCHES WITHOUT DIFFERENTIAL

ADJUSTMENT CONTROL):

1. Remove the pressure switch cover.

2. Adjust the range by turning the range adjustment screw clockwise

(in) to increase the cut-out point or counter-clockwise (out) to

decrease the cut-out point.

NOTE: One full turn changes the setting

approximately 2 PSIG.

3. Replace cover, reconnect power supply and start the compressor.

4. Note the pressure gauge reading at which the compressor cuts out.

5. Repeat adjustment procedure if necessary.

Pressure Switch Range Adjustment

ADJUSTMENT PROCEDURES (SWITCHES WITH DIFFERENTIAL

ADJUSTMENT CONTROL):

1. Remove the pressure switch cover.

2. Set the cut-in pressure with the range adjustment nut. Turn the nut

clockwise (in) to increase the pressure or counter-clockwise (out) to

decrease the pressure.

NOTE: One full turn changes the setting

approximately 2 PSIG.

3. Set the cut-out pressure with the differential adjustment. Turn the

differential adjustment nut clockwise (in) to increase the pressure

or counter-clockwise (out) to decrease the pressure.

NOTE: One full turn changes the setting

approximately 2 PSIG.

4. Replace the cover, reconnect the power supply and start the unit.

5. Note the pressure gauge reading at which the unit cuts out.

6. Repeat the adjustment procedure if necessary.

The minimum possible differential is approximately 20% of cutout

pressure. It is advisable to have as wide a differential as possible to

avoid frequent starting and stopping of the unit. Note the pressure

gauge reading at which the unit cuts-out and re-establish this point if

necessary.

Note the interaction between the range and differential adjustments,

i.e., if the cut-out is increased, the differential will also increase, or if the

differential is narrowed, the cut-out will be reduced, etc. These factors

must be considered when adjusting the switch and compensated for

accordingly.

ELECTRIC DRAIN TIMER SETTINGS

The "time off" setting determines the interval between cycles from

30 seconds to 45 minutes. The "time on" setting determines the actual

time the compressor drains condensate from the 1/4" or 1/2”

condensate outlet port.

The timer’s cycle rate and drain opening time should be adjusted to

open just long enough to discharge the condensate. The timer is

properly set when it opens and discharges condensate and then

vents air for approximately one second before closing. Adjustments

may be made depending on many factors, including humidity and duty

cycle.

OIL PRESSURE ADJUSTMENT (MODEL 2000P)

For pressure lubricated compressors, the oil pressure should be

checked upon start-up by observing the oil pressure gauge. The

acceptable operating range is 15-40 psig. It is normal for the oil

pressure to vary slightly with oil temperature. Compressors equipped

with an optional low oil pressure shutdown system will automatically

shut down if the oil pressure drops below 10 psig.

The oil pump is equipped with an adjustable pressure regulator which

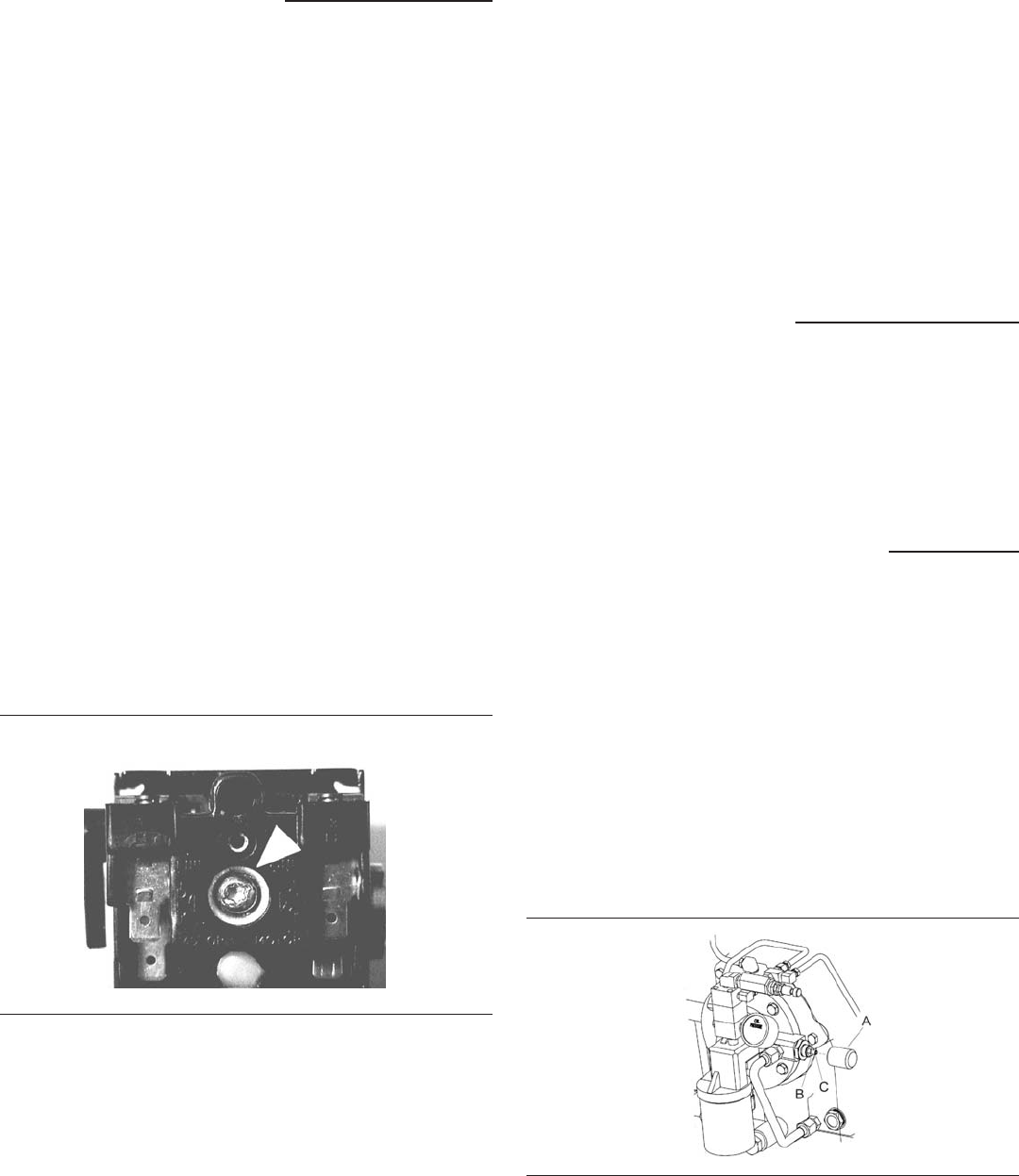

may be reset if conditions warrant. Refer to the following illustration

and instructions:

1. Use an adjustable wrench to remove the knurled cover for the

valve on the right side of the oil pump housing (A).

2. Loosen the retaining nut (B) with a 7/16” wrench such that the

threaded rod (C) is free to rotate.

3. Using a 1/8” hex key, adjust the threaded rod to the desired setting.

Turning the rod clockwise increases the oil pressure setting, and

turning the rod counterclockwise decreases the oil pressure.

4. When the oil pressure is set, tighten the retaining nut and replace

the knurled cover.

http://air.irco.com