MAINTENANCE

44

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

BELT CHANGE / GAS STRUT CHANGE PROCEDURE

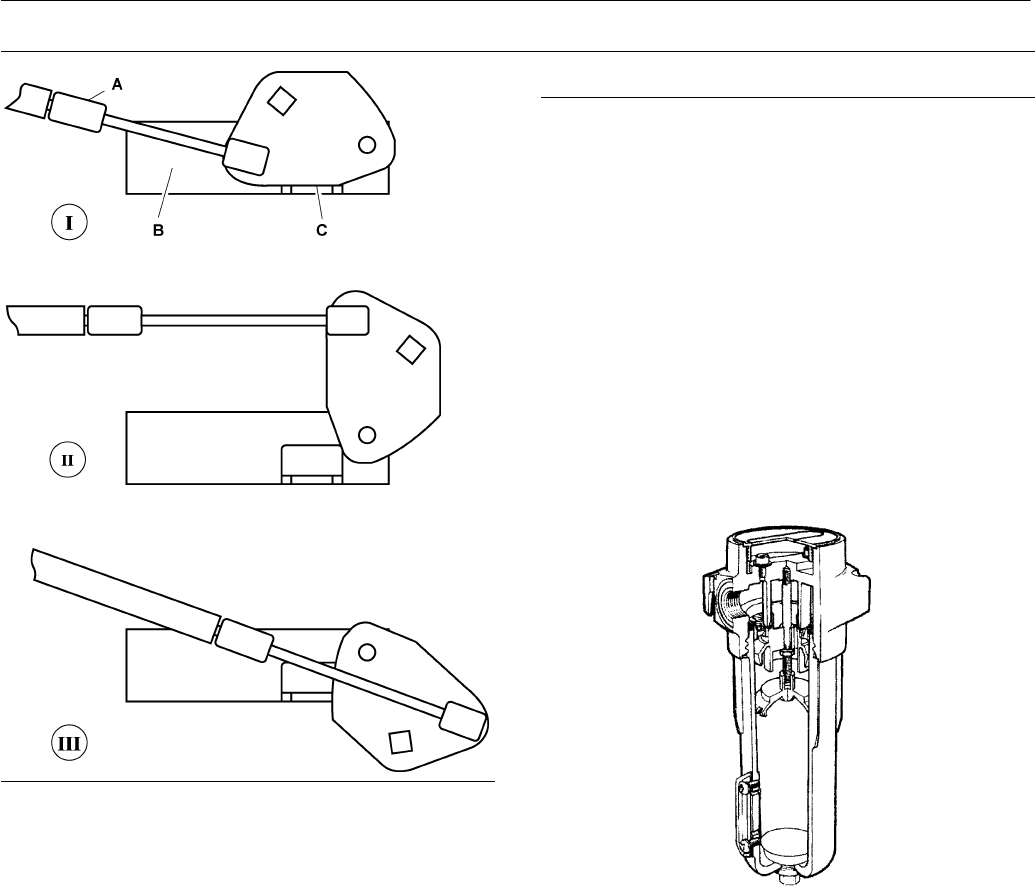

A. Gas strut.

B. Support bracket (part of pivoted assembly).

C. Tension cam.

1. Stop the machine, electrically isolate and vent all trapped pressure.

2. Remove the side cover from the machine.

3. Fit a

1

/

2

” square drive wrench in the tension cam located above the

airend (access from front door). Turn clockwise

1

/

4

turn to Position II

to release gas strut tension on the belts.

4. Using a small screwdriver under the spring clip, ease the ball ends

off the spherical studs at the ends of the gas strut.

5. Replace the gas strut and the studs at the same time by removing

and replacing the studs then pushing the new gas strut firmly onto the

studs until it clicks into place.

6. Turn the tension cam clockwise

1

/

4

turn to Position III to raise and

support the airend. Place a block of wood or similar under the separator

tank for support.

7. Replace the belts from the left side of the machine.

8. Turn the tension cam counter–clockwise

1

/2

turn to Position I to

tension the gas strut.

9. Spin the drive to check alignment of the belt ribs on the pulleys

(sheaves).

MOISTURE SEPARATOR MAINTENANCE

The moisture separator will operate indefinitely under normal working

conditions, however at some time it may be necessary to replace the

seals should the housing leak.

1. Isolate the housing from the air supply.

2. Fully depressurize in drain bowl as appropriate.

3. Unscrew bowl and remove. If pressure has not been completely

released from the housing, air will escape from the warning hole giving

an audible alarm. Screw back bowl and repeat instruction 2 before

attempting again. Should resistance to unscrewing be experienced,

provision is made for a ’C’ spanner to fit onto the ribs of the bowl.

4. Check condition of bowl seal and replace if necessary. Clean screw

threads.

5. Refit bowl with ’O’ ring seal.

6. Repressurize and check for leaks. If leaks occur they will most

probably be from the bowl ’O’ ring. Depressurize housing and remove

’O’ ring as stated above and inspect and clean. Ensure that mating

surfaces are clean and then refit ’O’ ring and repressurize.

http://air.ingersollrand.com