MAINTENANCE

45

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

ELECTRIC DRAIN VALVE

PRODUCT DESCRIPTION

The Electric Drain Valve removes condensed water and oil from the

moisture sepearator. Additional drains may be installed throughout your

compressed air system, including aftercoolers, filters, drip legs and

dryers.

The Electric Drain Valve operates on a timer which can be set to

automatically drain the air receiver tank at operator–determined

intervals.

Key features include:

• 100% continuous duty

• NEMA 4 enclosure

• Adjustable time on (0.5 – 10 seconds)

• Adjustable time off (0.5 – 45 minutes)

• Stainless steel operator

• LED to indicate electrical power is on

• LED to indicate valve is open

• Manual override

OPERATION

1. Open the strainer ball valve.

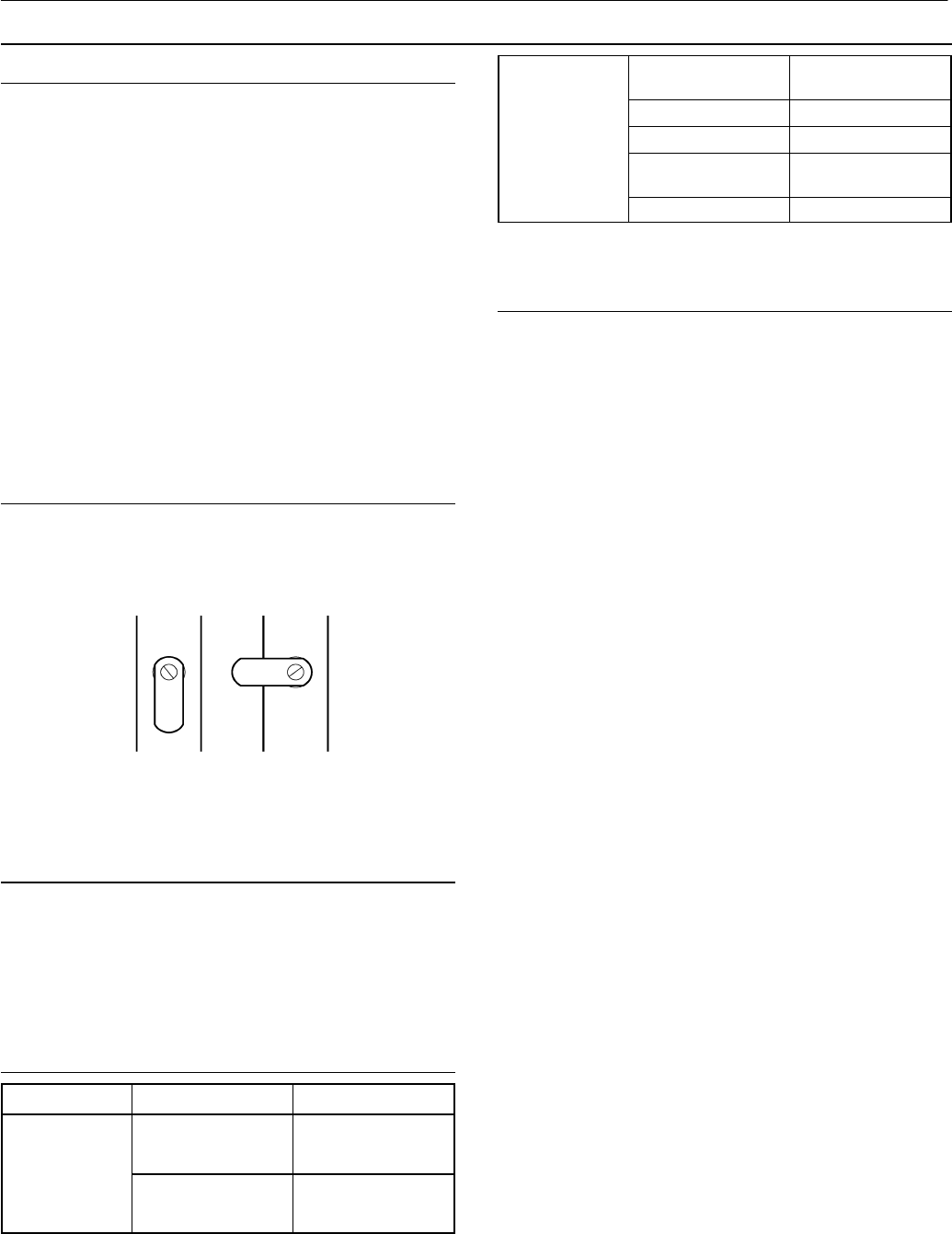

Strainer Ball Valve.

OPEN CLOSED

2. Set the “time off” and “time on” knobs. See TIMER SETTINGS

(below) for an explanation of the settings.

3. During compressor operation, check for air leaks.

TIMER SETTINGS

The “time off” setting determines the interval between cycles from 30

seconds to 45 minutes. The “time on” setting determines the actual time

the compressor drains condensate.

The timer’s cycle rate and drain opening time should be adjusted to

open just long enough to discharge the condensate. The timer is

properly set when it opens and discharges condensate and then vents

air for approximately one second before closing. Adjustments may be

made depending on many factors, including humidity and duty cycle.

TROUBLESHOOTING

TROUBLE CAUSE

ACTION

Valve will not

close.

1. Debris in solenoid

valve prevents dia-

phragm from seating.

1. Remove solenoid

valve, disassemble,

clean and reassemble.

2. Short in electrical

component.

2. Check and replace

power cord or timer as

needed.

Timer will not

activate

1. No electrical

supply.

1. Apply power.

2. Timer malfunction 2. Replace timer.

3. Clogged port. 3. Clean valve.

4 Solenoid valve

malfunction.

4. Replace solenoid

valve.

5. Clogged strainer. 5. Clean strainer.

MAINTENANCE

Periodically clean the screen inside the valve to keep the drain

functioning at maximum capacity. To do this, perform the following

steps:

1. Close the strainer ball valve completely to isolate it from the air

receiver tank.

2. Press the TEST button on the timer to vent the pressure remaining

in the valve. Repeat until all pressure is removed.

CAUTION! High pressure air can cause injury from flying debris.

Ensure the strainer ball valve is completely closed and pressure

is released from the valve prior to cleaning.

3. Remove the plug from the strainer with a suitable wrench. If you hear

air escaping from the cleaning port, STOP IMMEDIATELY and repeat

steps I and 2.

4. Remove the stainless steel filter screen and clean it. Remove any

debris that may be in the strainer body before replacing the filter screen.

5. Replace plug and tighten with wrench.

6. When putting the Electric Drain Valve back into service, press the

TEST button to confirm proper function.

http://air.ingersollrand.com