B-1

OPERATION

SAFETY PRECAUTIONS

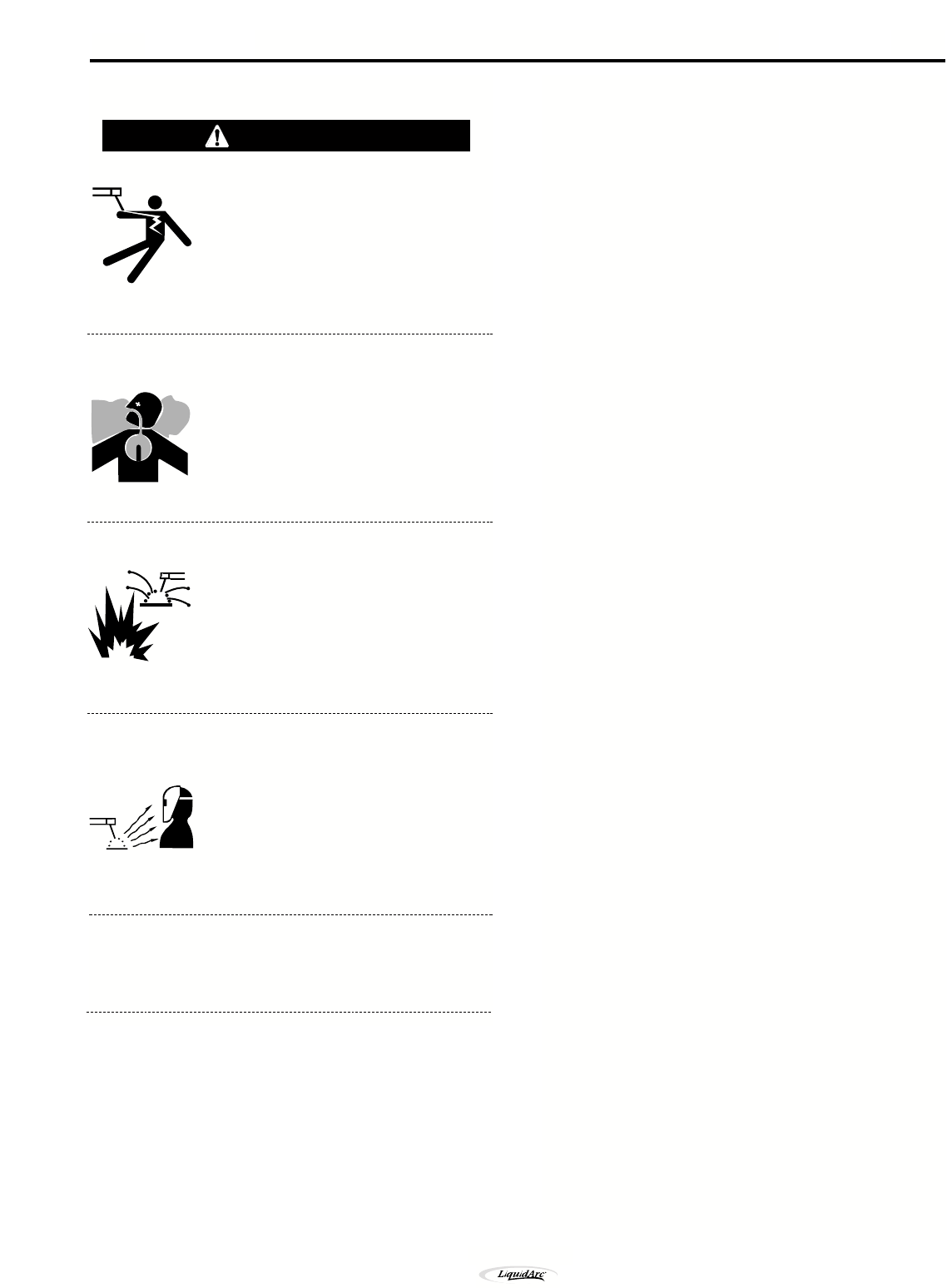

ELECTRIC SHOCK can kill.

• Do not touch electrically live

parts or electrode with skin or

wet clothing. Insulate yourself

from work and ground.

• Always wear dry insulating

gloves.

FUMES AND GASES can be

dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to

remove fumes from breathing

zone.

WELDING SPARKS can

cause fire or explosion.

• Keep flammable material away.

• Do not weld on closed contain-

ers.

ARC RAYS can burn eyes

and skin.

• Wear eye, ear and body protec-

tion.

See additional warning information at

front of this opeerator’s manual.

WARNING

GENERAL DESCRIPTION

The Handymig 170i is a complete semiautomatic con-

stant voltage DC portable arc welder. Included is a

tap-switch controlled, single phase constant voltage

transformer/rectifier power source and a wire feeder

with welding gun for feeding .023" (0.6 mm) through

.030" (0.8 mm) solid steel electrode. Optional kits are

available for .035" (0.9 mm) and .045" (1.2 mm)

Innershield

®

NR-211-MP.

It is ideally suited for individuals having access to 240

volts 50 Hz AC input power and want the ease of use,

quality and dependability of both gas metal arc weld-

ing or GMAW (also known as MIG welding) and the

Innershield

®

process (self-shielded flux-cored or

FCAW). A convenient chart is mounted inside the wire

feed section door for setting welding procedures for 24

gauge (.60 mm) through 5/16" (8.0 mm) mild steel.

The machine is rugged and reliable and has designed

for dependable service and long life.

RECOMMENDED PROCESSES

The Handymig 170i can be used for welding mild steel

using the GMAW, single pass, process which requires

a supply of shielding gas or it can be used with the

self-shielded, Innershield

®

process (FCAW).

OPERATIONAL FEATURES AND

CONTROLS

The Handymig 170i has the following controls as stan-

dard: Power ON/OFF Switch, Voltage Control, Wire

Speed Control, Trigger Switch, and a Circuit Breaker.

DESIGN FEATURES AND

ADVANTAGES

• “Cold electrode” until gun trigger is pressed for an

added measure of safety.

* Overload protection — incorporates both a thermo-

stat and a circuit breaker.

• Quality wire drive with electronic overload protection.

• “Quick Release” idle roll pressure arm is easily

adjusted.

• Reversible, dual groove drive roll, shipped ready to

feed .023"/.025" (0.6 mm) diameter wire. The drive

roll is easily reversed to feed .030" (0.8 mm) diame-

ter solid wire and .035" (0.9 mm) flux-cored diameter

wire. Optional drive roll included in .045" (1.2 mm)

Innershield

®

welding kit must be installed to feed

.045" (1.2 mm) flux-cored wire.

• No external shielding gas is required when used with

Liquid Arc steelcore 71T-GS electrode.

• Spindle accommodates both 8 in. (200 mm) diameter

and 4 in. (100 mm) diameter spools of wire.

B-1

Handymig 170i