E-4

E-4

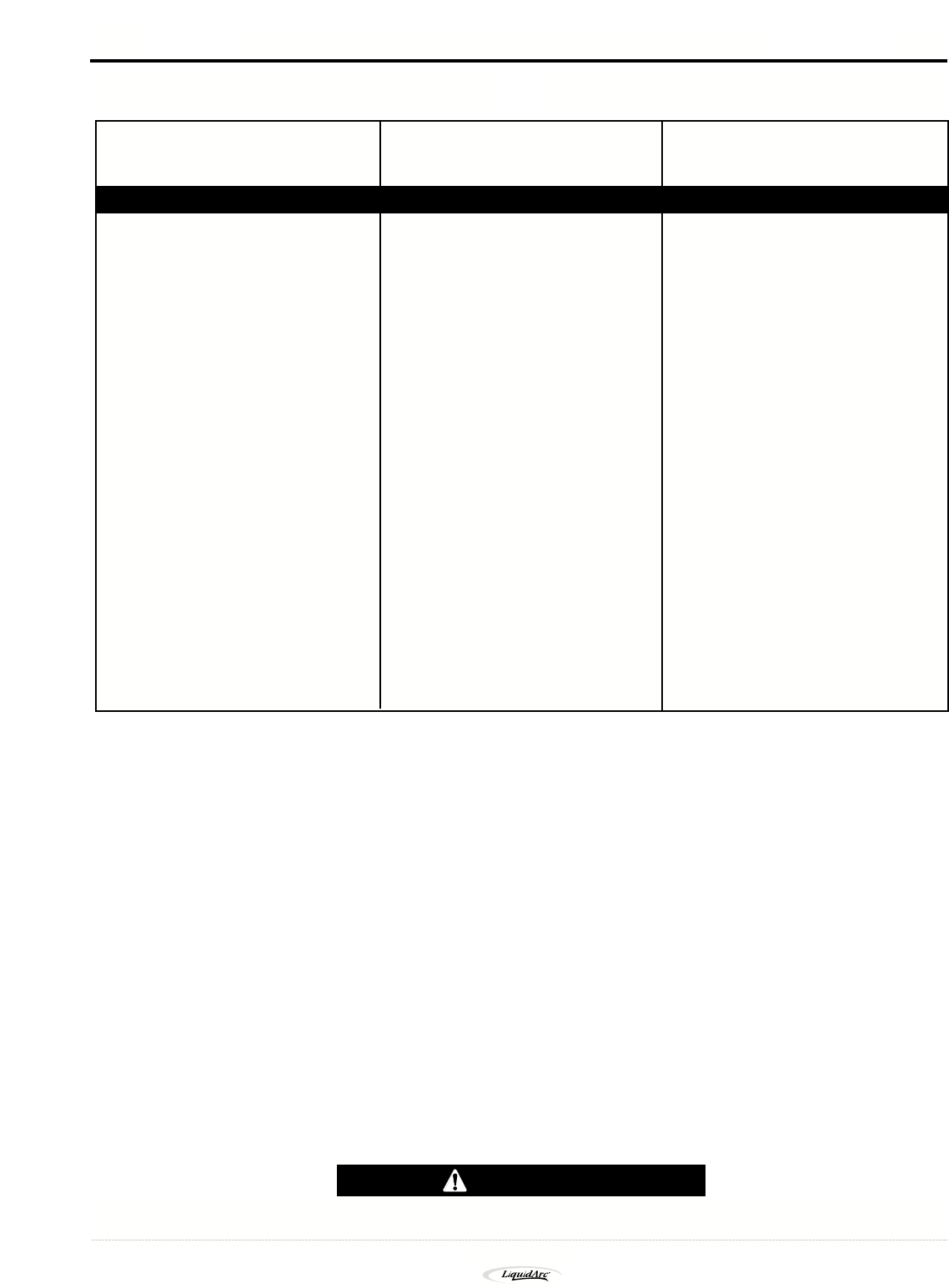

TROUBLESHOOTING

Observe Safety Guidelines

detailed in the beginning of this manual.

TROUBLESHOOTING GUIDE

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

LOCAL AUTHORIZED

LIQUID ARC FIELD SERVICE FACILITY for assistance before you proceed.

CAUTION

PROBLEMS

(SYMPTOMS)

Arc is unstable – Poor starting

POSSIBLE AREAS OF

MISADJUSTMENT(S)

1. Check for correct input voltage

to machine. See Installation sec-

tion, “Electrical Input

Connections”.

2. Check for proper electrode

polarity for process.

3. Check gun tip for wear or dam-

age and proper size – Replace.

4. Check for proper gas and flow

rate for process. (For MIG only.)

5. Check work cable for loose or

faulty connections.

6. Check gun for damage or

breaks.

7. Check for proper drive roll orien-

tation and alignment.

8. Check liner for proper size.

RECOMMENDED

COURSE OF ACTION

If all recommended possible areas

of misadjustments have been

checked and the problem persists,

contact your local Liquid Arc

Authorized Field Service Facility.

WELDING PROBLEMS

Handymig 170i