B-6B-6

OPERATION

The Handymig 170i is suitable for .035"(0.9mm) alu-

minum wire and .023"–.035"(0.6-0.9mm) stainless

wire. Refer to Table B.1 for recommended procedure

settings. (Requires K664-2 Aluminum - Stainless

Feeding Kit.)

It is important when changing between welding

with steel wire and aluminum to exchange feeding

components due to the lubricant applied to steel

wire. Failure to do so may result in contaminated

welds when welding aluminum.

------------------------------------------------------------------------

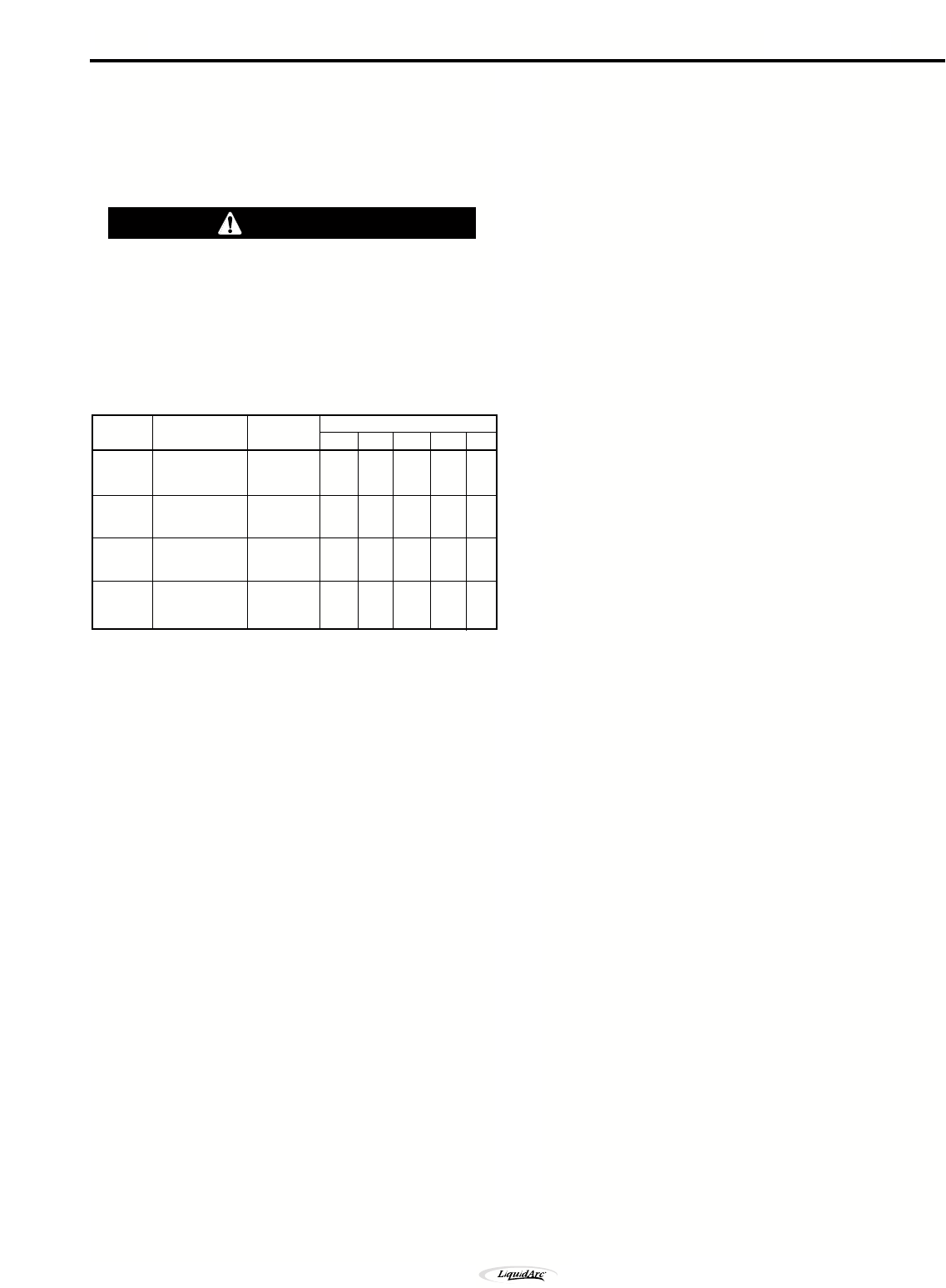

TABLE B.1 — Handymig 170i

CHANGING MACHINE OVER TO

FEED OTHER WIRE SIZES

The Handymig 170i is shipped from the factory ready

to feed 0.023”– .025" (0.6 mm) diameter wire. To

operate the Handymig 170i with other sizes of wire, it

is necessary to change the contact tip and change the

drive roll over to other sizes. Refer to Changing the

Contact Tip and Changing the Drive Roll, in the MAIN-

TENANCE section, for specific information on these

procedures.

WELDING WITH GMAW (MIG)

Shielding Gas

When using the GMAW process, install a gas regula-

tor and hose kit.

• For CO

2

, open the cylinder very slowly. For argon-

mixed gas, open cylinder valve slowly a fraction of

a turn. When the cylinder pressure gauge pointer

stops moving, open the valve fully.

• If using a regulator with an adjustable flow meter,

close the gun trigger and adjust the flow to give 15

– 20 cubic ft per hour (CFH) (7 – 10 I/min) [use 20

– 25 CFH (10 – 12 I/min) when welding out of posi-

tion or in a drafty location.

• Keep the cylinder valve closed, except when using

the Handymig 170i. When finished welding:

• Close the cylinder valve to stop gas flow.

• Depress the gun trigger briefly to release the

pressure in the gas hose.

• Turn off the Handymig 170i.

WELDING WITH FCAW (Innershield)

When using the FCAW process, the correct drive roll

and electrode polarity must be used. See Work Cable

Installation in INSTALLATION section for changing the

polarity.

Use optional Innershield welding kit K549-1 (for 0.9

mm) or K549-2 (for 1.2 mm), as appropriate.

• K549-1 0.9mm (.035”) Innershield® Welding Kit—

Includes a contact tip, a gasless nozzle and a 0.9-

1.2mm cable liner to permit the Magnum™ 100L gun

and cable to use 0.9mm diameter flux-cored elec-

trode. The fitting on the end of the liner is stencilled

with the maximum rated wiresize (.045”/1.2mm). Also

included is a spool of 0.9mm

Innershield® NR-211-MP.

• K549-2 1.2mm (.045”) Innershield® Welding Kit—

Includes a contact tip, a gasless nozzle and a 0.9-

1.2mm cable liner to permit Magnum™ 100L gun

and cable to use 1.2mm diameter flux-cored elec-

trode. The fitting on the endof the liner is stencilled

with the maximum rated wire size (.045”/1.2mm).

Also included is a spool of 1.2mm Innershield® NR-

211-MP and a knurled drive roll.

Several changes are needed to convert the unit for

operation with the Innershield (FCAW) process. The

K549-1 or K549-2 Innershield Kits include all the nec-

essary accessories for this conversion and are provid-

ed for this purpose. The following conversions should

be made using the contents of this kit:

• Change the output polarity to DC(-). See “Work

Cable Installation” in Installation Section for details.

• Install proper drive roll for wire size selected. See

“Changing Drive Roll” in Maintenance Section for

details.

• Install the proper gun liner and tip for the wire size

selected. See “Component Replacement” in the

Maintenance Section for details.

• Remove gas nozzle (if installed) and install gasless-

nozzle. To remove, simply unscrew.

• Load wire into machine and thread into gun and

cable per “Welding Wire Loading” section.

Shielding

Voltage/Wire Speed

Process Welding Wire Gas 16 ga 14 ga 12 ga 10 ga 3/16

MIG DC+ .035 Dia 100% Argon A-5 B6.5 C-8 D-8.5 E-10

4043/5356

Aluminum Wire

MIG DC+ .023 Dia 98% Argon/ A-4 B-6 C-8 ——

308L Stainless 2% Oxygen

Steel Wire

MIG DC+ .030 Dia 98% Argon/ B-3.5 C-6.5 D-7 E-8 E-9

308L Stainless 2% Oxygen

Steel Wire

MIG DC+ .035 Dia 98% Argon/ B-2.5 C-4 D-6 E-8 E-8

308L Stainless 2% Oxygen

Steel Wire

CAUTION

Handymig 170i