B-14

OPERATION

B-14

POWER WAVE® C300 CE

ALUMINUM SYNERGIC GMAW-P

(PULSED MIG)AND GMAW-PP

(PULSE ON PULSE) WELDING

The POWER WAVE® C300 CE can produce top qual-

ity aluminum welds with excellent appearance, little

spatter and good bead shape. Push-pull guns are

available for consistent feeding when welding a long

distance away from the wire feeder.

PULSE-ON-PULSE WELDING

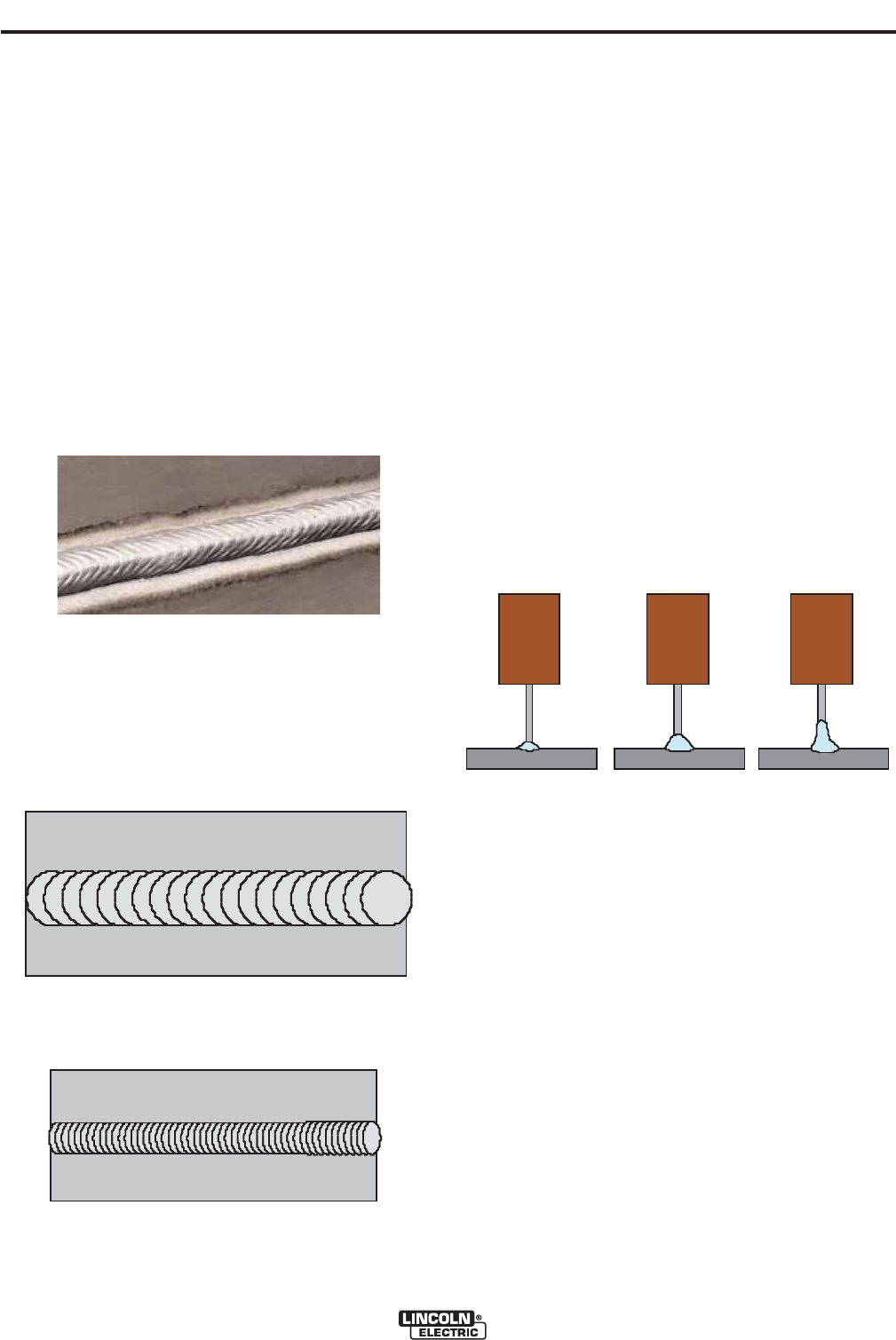

The Power Wave system offers both traditional pulse

and Pulse-on-Pulse™. Pulse-on-Pulse (GMAW-PP)

is an exclusive waveform for aluminum welding. Use

it to make welds with a "stacked dime" appearance,

similar to GTAW welds.( See Figure B.7)

FIGURE B.7

The pulsing frequency is adjustable. Changing the fre-

quency modulation (or arc control) of the waveform

changes the ripple spacing. Faster travel speeds may

be achieved by using higher values of frequency mod-

ulation. ( See Figure B.8 and B.9p)

FIGURE B.8

Frequency Modulation = -10

Wide weld and ripple spacing, slow travel speed.

Frequency Modulation = 10

Narrow weld and ripple spacing, fast travel speed.

FIGURE B.9

ALUMINUM GMAW-P AND GMAW-PP

ALUMINUM PULSE WELDING

Synergic GMAW-P (Pulsed MIG) welding is ideal for

low spatter, out of position and reduced heat input

applications. During pulse welding, the welding cur-

rent continuously switches from a low level to a high

level and then back again. Each pulse sends a small

droplet of molten metal from the wire to the weld pud-

dle.

Pulse welding controls the arc length with 'Trim'

instead of voltage. When trim (arc length) is adjusted,

the Power Wave automatically recalculates the volt-

age, current and time of each part of the pulse wave-

form for the best result. Trim adjusts the arc length

and ranges from 0.50 to 1.50, with a nominal value of

1.00 for a 3/4" (19mm) electrode stick-out. Trim values

greater than 1.00 increase the arc length, while values

less than 1.00 decrease the arc length.

(See Figure B.10)

Trim .50

Arc Length Short

Trim 1.00

Arc Length Medium

Trim 1.50

Arc Length Long

FIGURE B.10