SShhiieellddiinngg

GGaass

IIddlleePPrreefflloowwSSttrriikkeeUUppssllooppeeWWeellddBBuurrnnbbaacckkPPoossttfflloowwIIddllee

WWFFSS

OOnn

OOffff

RRuunn--iinn

OOffff

WWeelldd

OOffff

WWeelldd

Arc Arc EstablishedEstablished

Trigger Trigger PulledPulled

Trigger Trigger ReleasedReleased

11..55 sseecc mamaxx..

StStaartrt

SSttaarrtt ttimeime

BBuurrnnbbaacckk TimeTime

DDoowwnnslslooppee

CCraratteerr

CCrraatteerr ttiimeme

PPoo

ww

erer

SSoouurrcece

OOuuttppuutt

CCraratteerr

SShhiieellddiinngg

GGaass

IIddllee PPrreeffllooww SSttrriikkee UUppssllooppee WWeelldd BBuurrnnbbaacckk PPoossttffllooww IIddllee

WWFFSS

OOnn

OOffff

RRuunn--iinn

OOffff

WWeelldd

OOffff

WWeelldd

Arc Arc EstablishedEstablished

Trigger Trigger PulledPulled

Trigger Trigger ReleasedReleased

11..55 sseecc mamaxx..

StStaartrt

SSttaarrtt ttimeime

BBuurrnnbbaacckk TimeTime

DDoowwnnslslooppee

CCraratteerr

CCrraatteerr ttiimeme

PPoo

ww

erer

SSoouurrcece

OOuuttppuutt

CCraratteerr

,)

&')+ &%

*+'+) )&')+ &%

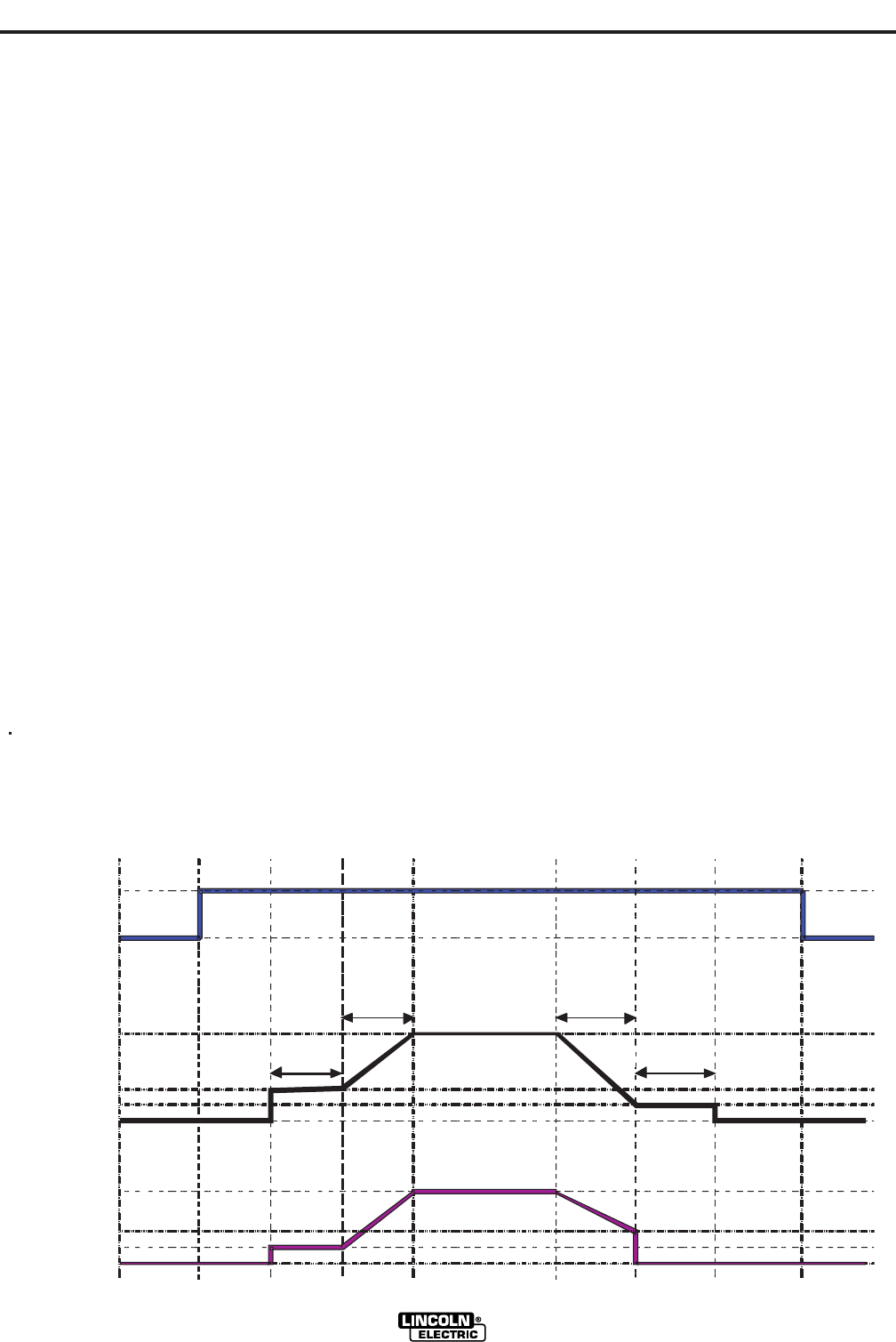

(See Figure B.4)

Sometimes it is advantageous to set specific arc start,

crater and arc ending parameters for the ideal weld.

Many times when welding aluminum crater control is

necessary to make a good weld. This is done by set-

ting Start, Crater and Burnback functions to desired

values.

*(,%&&')+ &%

Following is the total weld sequence that the Power

Feed™ 10M Single Wire Feeder will execute. If any

parameter is inactive or its time is set to zero, the weld

procedure immediately shifts to the next parameter in

the sequence.

1. PREFLOW: Shielding gas begins to flow immedi-

ately when the gun trigger is pulled.

2. STRIKE: After preflow time expires, the power

source regulates to the start output and wire is

advanced towards the work piece at the Strike

WFS. If an arc is not established within 1.5 sec-

onds, the power source output and wire feed speed

skips to the weld settings.

3. UPSLOPE: Once the wire touches the work and an

arc is established, both the machine output and the

wire feed speed ramp to the weld settings through-

out the start time. The time period of ramping from

the start settings to the weld settings is called UPS-

LOPE.

4. WELD: After upslope, the power source output and

the wire feed speed continue at the weld settings.

5. CRATER: As soon as the trigger is released, the

wire feed speed and power source output ramp to

the crater settings throughout the crater time. The

time period of ramping from the weld settings to the

crater settings is called DOWNSLOPE.

6. BURNBACK: After the crater time expires, the wire

feed speed is turned OFF and the machine output

continues for the burnback time.

7. POSTFLOW: Next, the machine output is turned

OFF and shielding gas continues until the post flow

timer expires.

'&.)S$* %#. ))