6

LEARNING TO STICK WELD

6

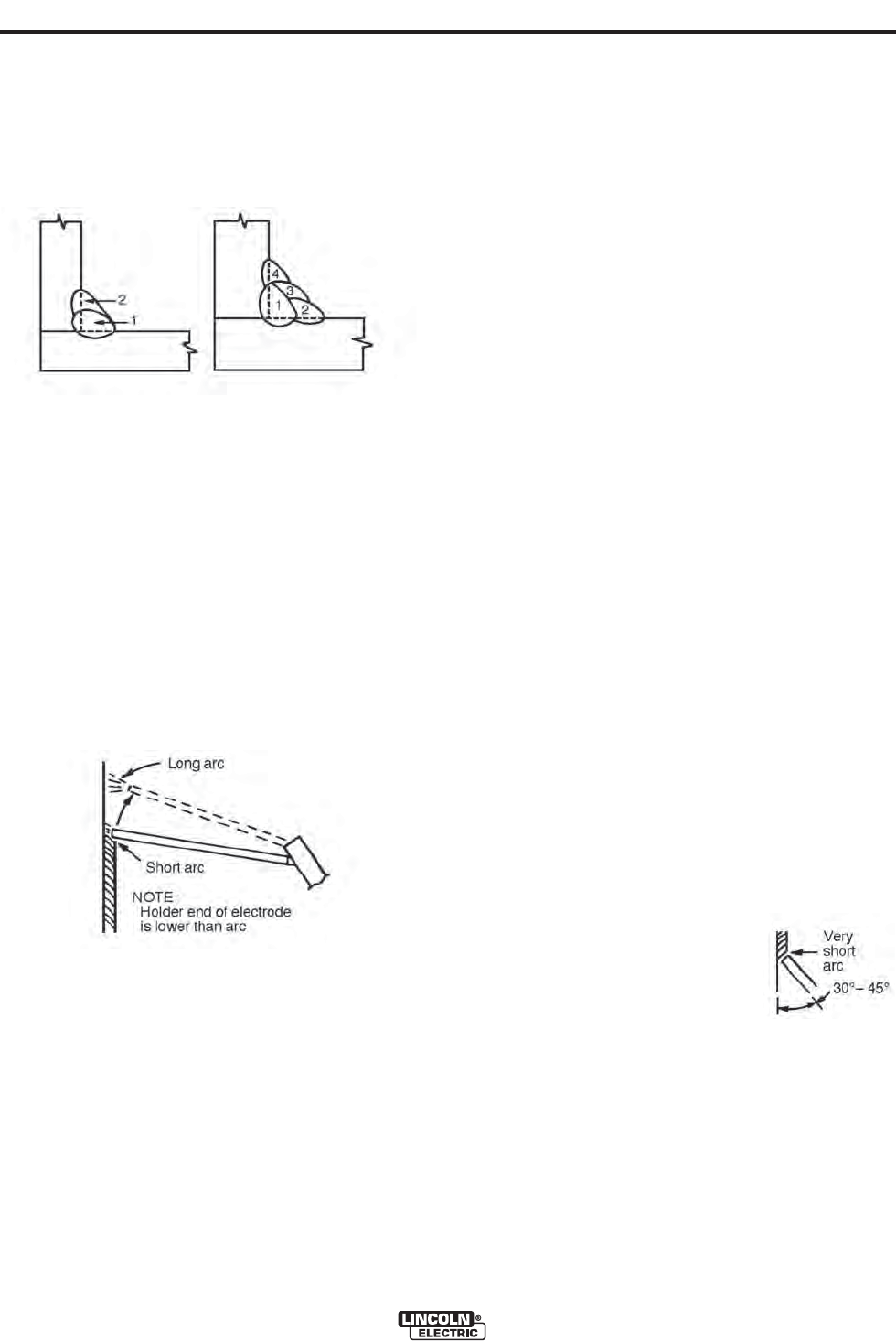

Multiple Pass Welds

Make multiple pass horizontal fillet joints as shown in

the sketch. Put the first bead in the corner with fairly

high current. Hold the electrode angle needed to

deposit the filler beads as shown putting the final bead

against the vertical plate.

Welding in the Vertical Position

Welding in the vertical position can be done either ver-

tical-up or vertical-down. Vertical-up is used whenever

a large, strong weld is desired. Vertical-down is used

primarily on sheet metal for fast, low penetrating

welds.

Vertical-Up Welding

The problem, when welding vertical-up, is to put the

molten metal where it is wanted and make it stay

there. If too much molten metal is deposited, gravity

will pull it downwards and make it “drip.’’ Therefore a

certain technique has to be followed:

1. Use 1/8" (3.2mm) at 90-105 amps or 3/32" (2.4mm)

at 60 amps Fleetweld® 180 electrode.

2. When welding, the electrode should be kept hori-

zontal or pointing slightly upwards. (See drawing.)

3. The arc is struck and metal deposited at the bottom

of the two pieces to be welded together.

4. Before too much molten metal is deposited, the arc

is SLOWLY moved 1/2”-3/4" (12.5-19mm) upwards.

This takes the heat away from the molten puddle,

which solidifies. (If the arc is not taken away soon

enough, too much metal will be deposited, and it

will “drip.’’)

5. The upward motion of the arc is caused by a very

slight wrist motion. Most definitely, the arm must not

move in and out, as this makes the entire process

very complicated and difficult to learn.

6. If the upward motion of the arc is done correctly

with a wrist motion, the arc will automatically

become a long arc that deposits little or no metal.

(See drawing.)

7. During this entire process the ONLY thing to watch

is the molten metal. As soon as it has solidified, the

arc is SLOWLY brought back, and another few

drops of metal are deposited. DO NOT FOLLOW

THE UP AND DOWN MOVEMENT OF THE ARC

WITH THE EYES. KEEP THEM ON THE MOLTEN

METAL.

8. When the arc is brought back to the now solidified

puddle, IT MUST BE SHORT, otherwise no metal

will be deposited, the puddle will melt again, and it

will “drip.”

9. It is important to realize that the entire process con-

sists of SLOW, DELIBERATE movements. There

are no fast motions.

Vertical-Down Welding

Vertical-down welds are applied at a fast pace. These

welds are therefore shallow and narrow, and as such

are excellent for sheet metal. Do not use the vertical-

down technique on heavy metal. The welds will not be

strong enough.

1. Use 1/8” (3.2mm) or 3/32" (2.4mm) Fleetweld® 180

electrode.

2. On thin metal, use 60-75 amps. (14 ga 75 amps —

16 ga 60 amps.)

3. Hold the electrode in a 30-45° angle with the tip of

the electrode pointing upwards.

4. Hold a VERY SHORT arc, but do

not let the electrode touch the

metal.

5. An up and down whipping motion

will help prevent burn-through on

very thin plate.

6. Watch the molten metal carefully.

The important thing is to continue lowering the entire

arm as the weld is made so the angle of the electrode

does not change. Move the electrode so fast that the

slag does not catch up with the arc. Vertical-down

welding gives thin, shallow welds. It should not be

used on heavy material where large welds are

required.