8

LEARNING TO STICK WELD

8

Hardfacing of Idler and Roller (Metal to Metal Wear)

A very common application of hardfacing for metal to

metal wear is the hardfacing of idlers and rollers and

the rails that ride on these rollers and idlers.

The reason for hardfacing these parts is primarily

monetary. A few dollars worth of electrode will com-

pletely build up a roller or idler, and the hard surface

will outlast several times the normal life or such rollers

and idlers.

If the following procedure is followed, it is not even

necessary to remove the grease bearing while weld-

ing. This will save a lot of time:

1. The roller (or idler) is inserted on a piece of pipe

that is resting on two sawbucks. This enables the

operator to turn it while welding.

2. Use Wearshield™ BU electrodes, 5/32" (4.0mm) at

175 amps or 3/16" (4.8mm) at 200 amps.

3. Weld across the wearing surface. Do not weld

around.

4. Keep the roller (or idler) cool by quenching with

water, and by stopping the welding periodically.

This will prevent shrinking of the roller (or idler) on

the grease bearing.

5. Build-up to dimension. The weld metal deposited by

Wearshield™ BU electrode is often so smooth that

machining or grinding is not necessary.

NOTE: The quenching of the roller (or idler) has

another purpose: It increases the hardness — and

thus the service life — of the deposit.

The hardfacing of the rails is a lot easier:

1. Place the rails with the side that rides on the rollers

and idlers upwards.

2. Use Wearshield™ BU electrodes, 5/32" (4.0mm) at

175 amps or 3/16" (4.8mm) at 200 amps.

3. Build-up to size.

4. Do not quench. This will make the deposit slightly

softer than the deposit on the idlers and rollers.

That means that the wear will primarily be on the

rails, which are a lot easier and less time-consum-

ing and cheaper to build-up.

NOTE: The same electrode — Wearshield™ BU —

will give the operator two desired hardnesses, just by

a difference in cooling rate, making it possible to put

the hardest deposit on the most expensive parts.

NOTE: The outside of the rails (the side that comes in

contact with the ground) should be surfaced with

Wearshield™ ABR, since this side has Metal to

Ground wear.

Welding Cast Iron

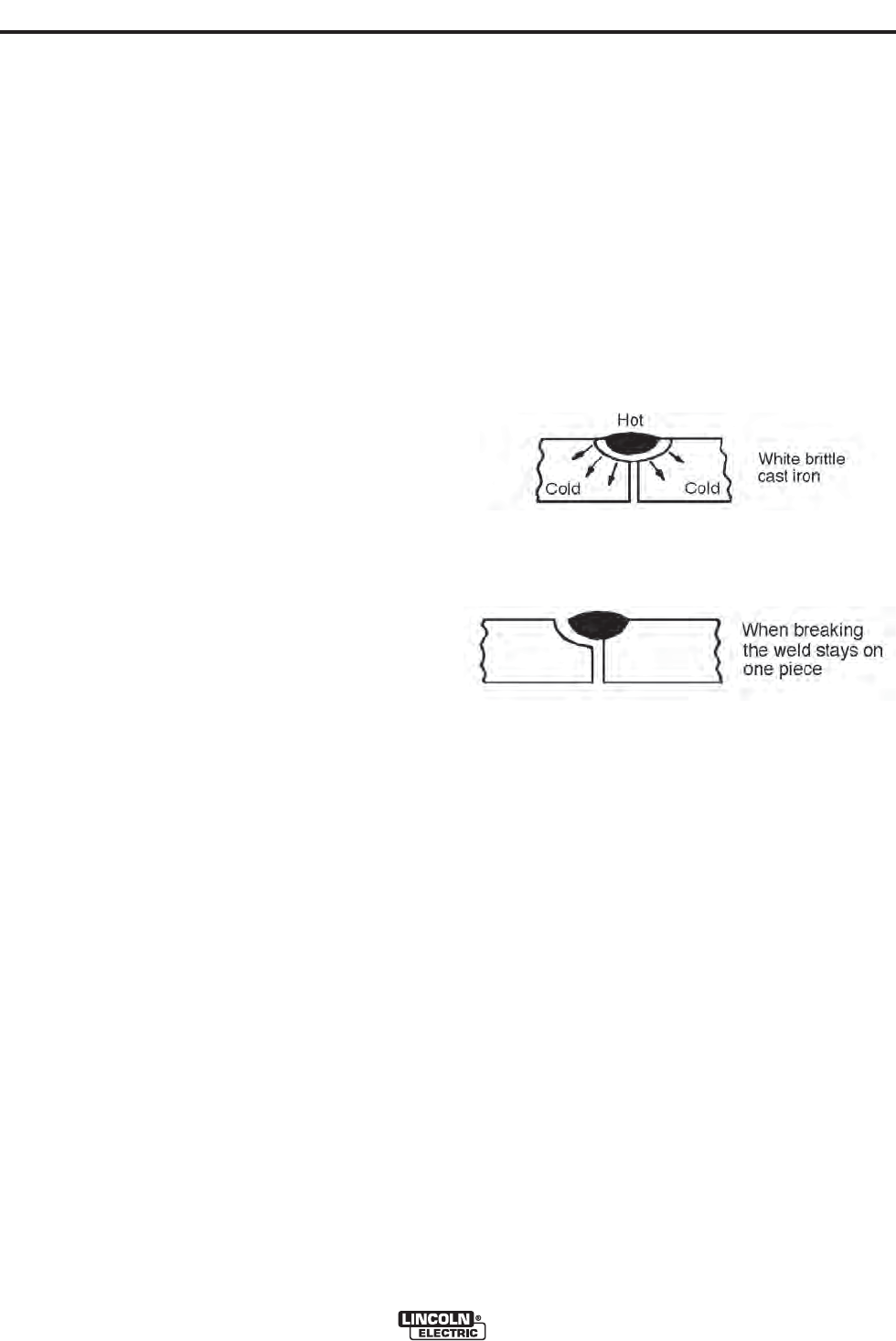

When welding on a piece of cold cast iron, the

tremendous heat from the arc will be absorbed and

distributed rapidly into the cold mass. This heating

and sudden cooling creates WHITE, BRITTLE cast

iron in the fusion zone.

This is the reason why welds in cast iron break.

Actually, one piece of the broken cast iron has the

entire weld on it, and the other piece has no weld on

it.

In order to overcome this, the welding operator has

two choices:

1. He can preheat the entire casting to 500-1200°F.

(260-649°C). If the cast iron is hot before welding,

there will be no sudden chilling which creates brittle

white cast iron. The entire casting will cool slowly.

2. He can weld 1/2" (12.5mm) at a time, and not weld

at that spot again until the weld is completely cool

to the touch.

In this way no large amount of heat is put into the

mass.

Most inexperienced welders will probably use the sec-

ond method, because they have no way of preheating

large castings. Smaller castings can easily (and

should) be preheated before welding. A forge, stove, a

fire, or the Arc Torch are all excellent means of pre-

heating.

When using the 1/2" (12.5mm) at a time method, it is

recommended to start 1/2" (12.5mm) away from the

previous bead and weld into the previous bead (back-

stepping).