F-31

TROUBLESHOOTING & REPAIR

F-31

NA-5

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric

Service Department for technical troubleshooting assistance before you proceed. Call 216-383-2531 or 1-800-833-9353.

CAUTION

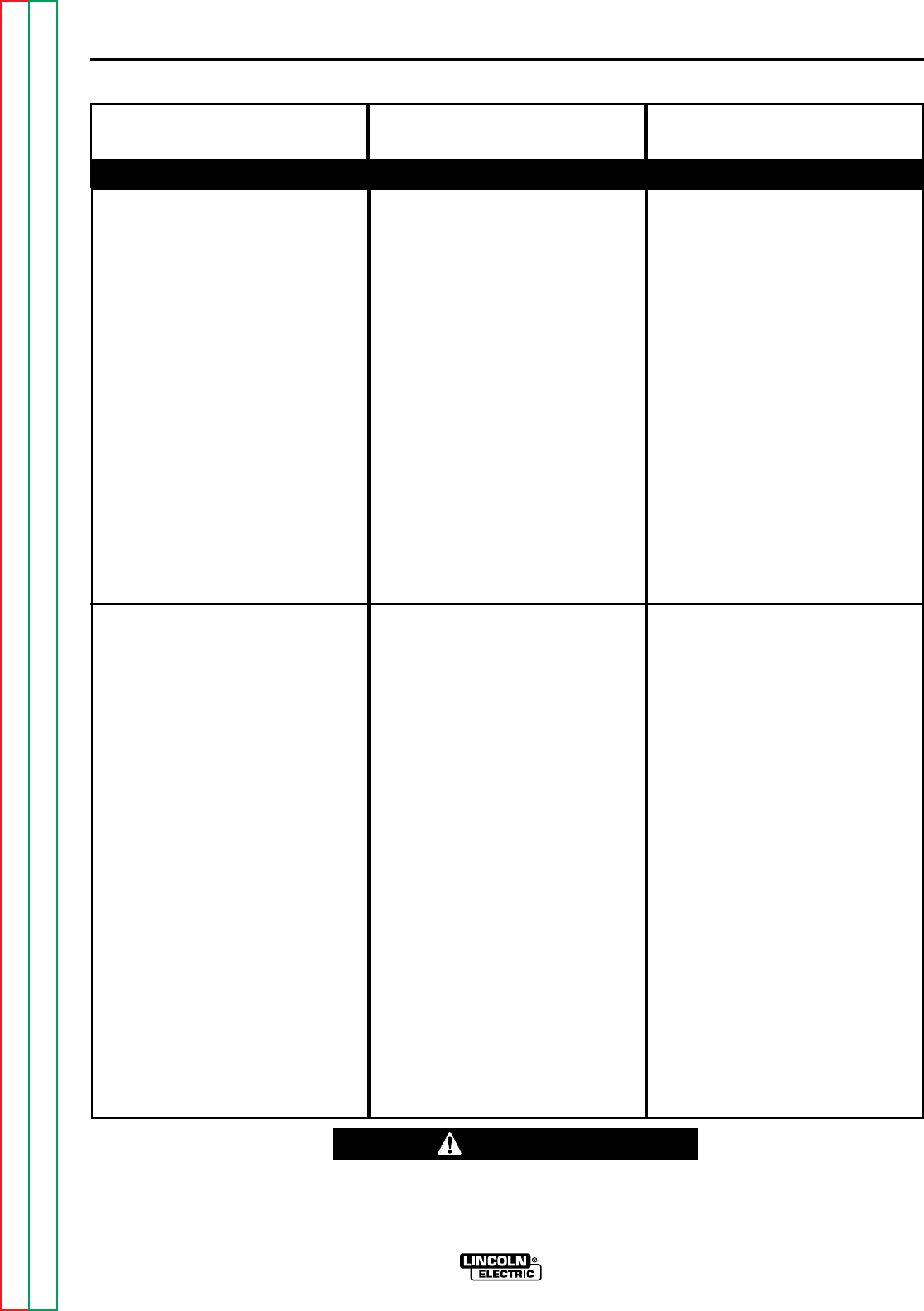

STARTING/WELDING PROBLEMS

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

The arc voltage appears to rise too

slowly. The wire stubs or blasts off

at the start of the weld sequence.

Once the arc is established the weld-

ing is OK.

The voltage seems too high or flares

excessively at the start of the weld

sequence. Once the arc is estab-

lished the welding is OK.

1. Increase the strike and or start

voltage settings.

2. Put the output control switch (on

the power source) in the

“Machine Control” position.

Jumper the “BYPASS “ pins on

the NA-5 voltage board. Control

the arc voltage from the power

source. If the problem is NOT

remedied the power source may

be at fault. If the problem is

solved the NA-5 may be at fault.

3. If the start response jumper, on

the voltage board, is in the “B”

position, change to the “A” posi-

tion. If the “A” position cures the

starting problem the voltage

board may be faulty.

1. Decrease the strike and or start

voltage settings.

2. Put the output control switch (on

the power source) in the

“Machine Control” position.

Jumper the “BYPASS” pins on

the voltage board. Control the

arc voltage from the power

source. If the problem is NOT

remedied the power source may

be at fault. If the problem is

solved the NA-5 may be at fault.

1. The voltage board may be faulty.

Replace.

1. The voltage board may be faulty.

Replace.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC