F-51

TROUBLESHOOTING & REPAIR

F-51

PROCEDURE

1. Make sure the electrode wire is fed

through the wire contact assembly

tip but NOT touching the "work"

piece.

2. Disconnect input power to the NA-5.

3. Make sure the drive motor cable and

power source control cables are

properly connected to the NA-5 con-

trol box.

4. Using the 5/16" nutdriver open the

control box PC board access door.

5. Locate the TS1 terminal strip. See

wiring diagram.

6. Using the ohmmeter check the resis-

tances per the following table F.2

7. Reconnect the welding cable leads

to the contact assembly.

8. If any of the resistances are not cor-

rect per Table F.2 check the associ-

ated leads, cables and circuits for

"opens" or "shorts". See wiring dia-

gram.

9. Close and secure the control box

access door.

EXTERNAL RESISTANCE TEST (LEADS #21 AND #67) (Continued)

NA-5

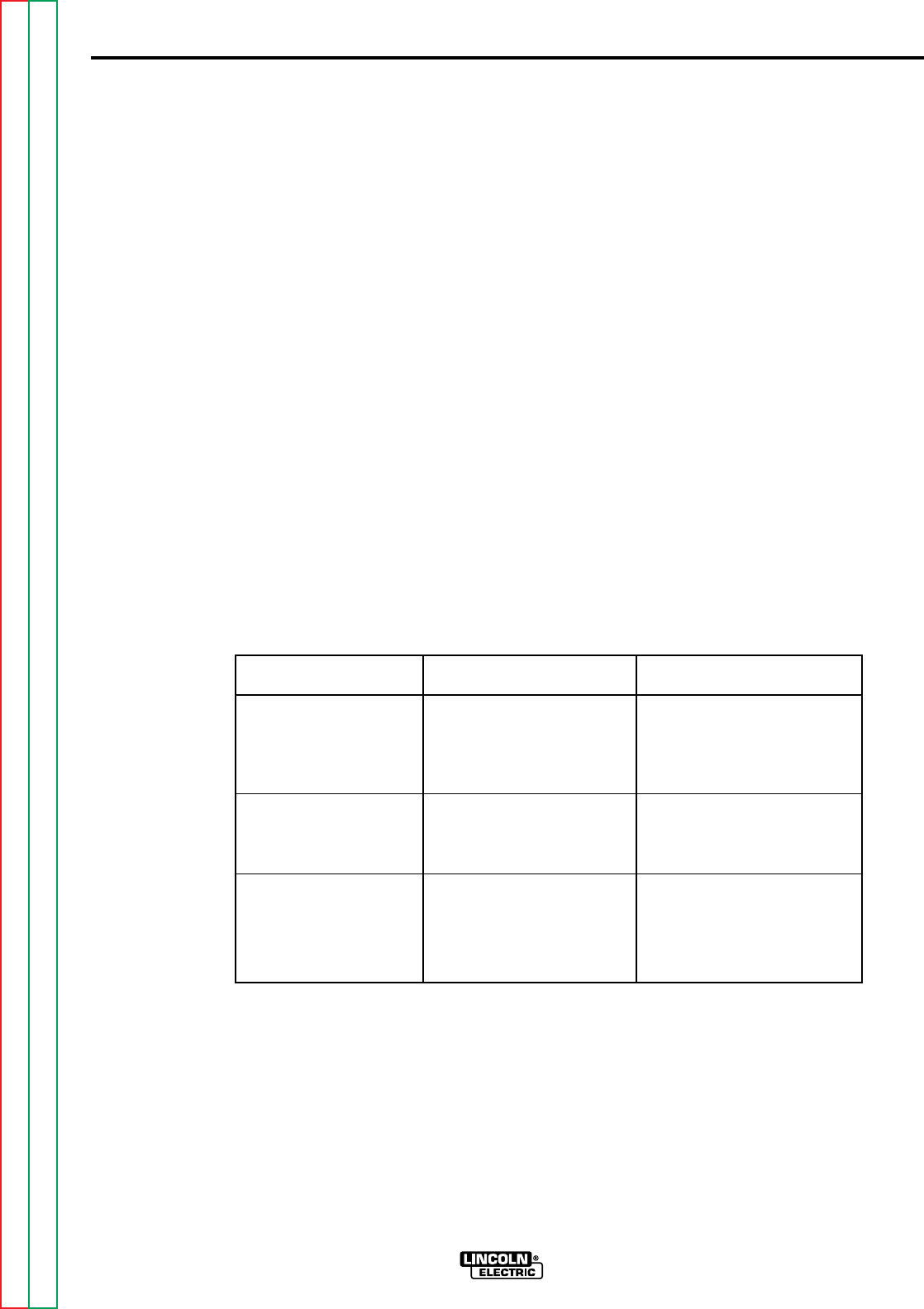

TEST POINTS EXPECTED COMMENTS AND

RESISTANCES CONDITIONS

Lead #667 Zero or less than Electrode wire must be in

to 1 ohm contact assembly tip

Electrode wire

Lead #621 to Zero or less than Polarity switches must be

work piece 1 ohm in the correct positions

Lead #667 to Greater than 15K Using the 3/4" wrench

#621 ohms disconnect the welding

cable(s) from the

contact assembly

TABLE F.2 EXTERNAL VOLTAGE SENSING LEADS TEST POINTS

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC