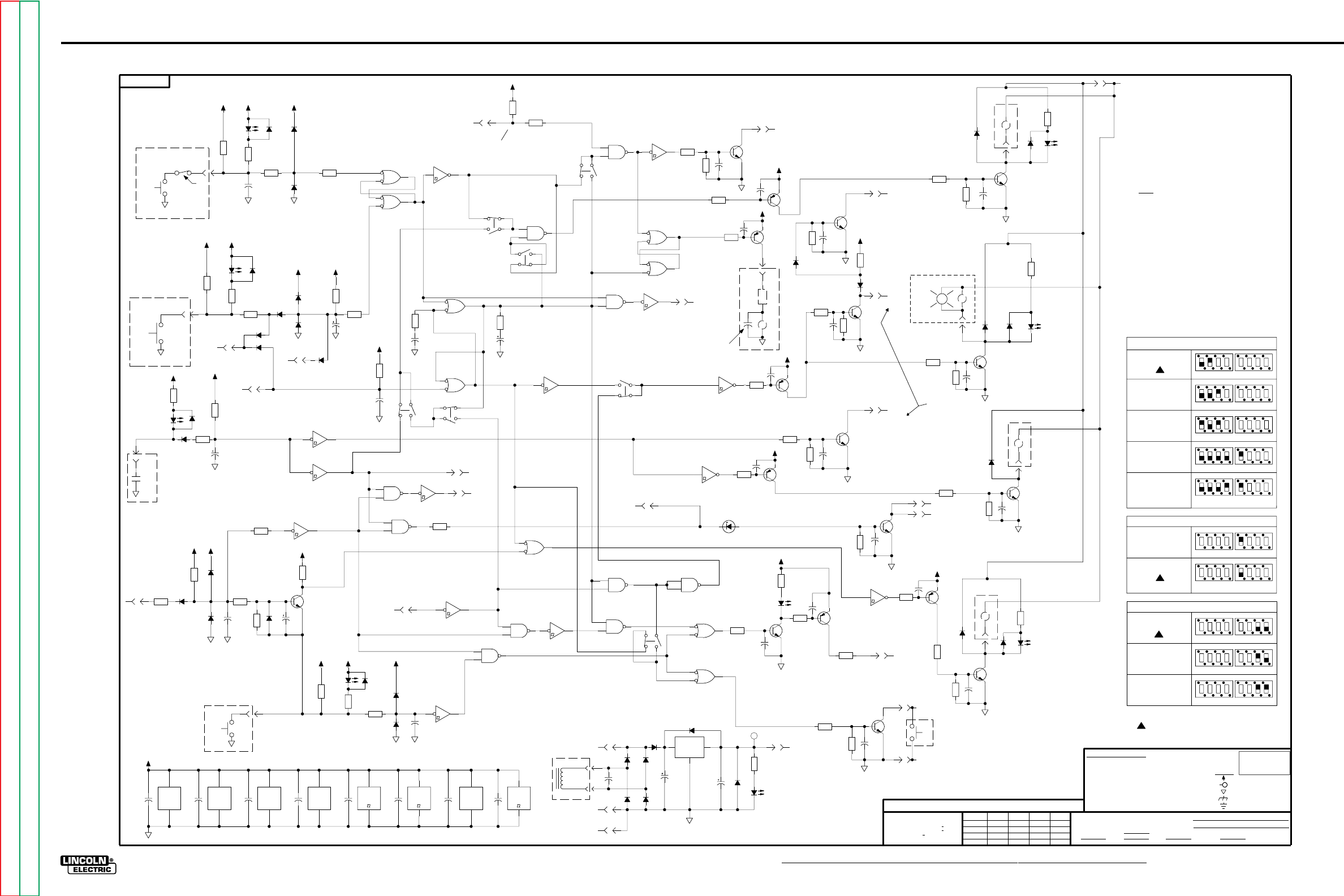

G-4

ELECTRICAL DIAGRAMS

NA-5

LOGIC PC BOARD (L6242-2 & above) SCHEMATIC

3

2

1

3

4

SWITCH #2

4

4

1

4

2

3

4

1

2

3

44

4

SWITCH #1

SWITCH #2

2

Inch up with no contactor

delay

Methods of Burnback

1

1

SWITCH #2

3

SWITCH #2

4

3

1

2 4

4

D30

1.00K

R36

X6

7

14

1.50K

R38

D33

50V

.022

C3

D34

4011

X2

14

7

C17

D35

4011

X4

14

7

4011

X1

14

7

C18

X5

7

14

C16

C15

4011

X3

14

7

C28

100

R50

X8

6

5

J5

5

LED 7J

D31

50V

.022

C2

4.7

35V

C9

J3

1

47.5K

R16

X6

12

13

221K

R15

F

100

R35

D17

Q1

2N4401

500

C29

500

500

515

515

515

500500

500

515

INCH

S4

DOWN

592

C

PROCEDURE

PC BOARD

583C

PRESENT

VOLTAGE

50V

.022

C14

Q16

2N4403

LED 7E

100K

R58

J5

4

100

R49

7.68K

R46

J3

5

7.68K

R48

X8

4

3

Q10

2N4401

50V

.022

C23

J3

9

2.67K

R28

Q17

2N4403

475

R32

C33

2.67K

R23

515

500

500

515

515

A

587

FEED FORWARD

(TO POWER P.C. BOARD)

B

STRIKE

PROCEDURE

ENABLE

563

563

688

ENABLE

SHUT DOWN

ENABLE

ARC CONTROL

DISABLE

STRIKE PROCEDURE

561

B

A

TIME

INITIATE

CRATER

TIME OVER

BURNBACK

X2

4

5

6

J3

4

X4

4

5

6

1W

5.1V

DZ1

J3

6

C34

1.50K

R47

22.1K

R45

Q15

2N4401

100K

R57

22.1K

R33

C35

C36

E

Q7

2N4401

X2

3

2

1

C

B

X4

3

2

1

B

PC BOARD

PROCEDURE

Q14

2N4403

C26

15.0K

R34

X3

3

2

1

X5

6

5

X2

12

13

11

X4

11

12

13

7.68K

R44

X8

2

1

J2

6

S1

6

12

11

5

X6

10

11

22.1K

R39

X6

4

3

J3

7

X6

6

5

X6

8

9

50V

.022

C4

682

7.68K

R43

CURRENT

C37

S2

8

10

9

7

X5

10

11

D26

500

681

1A

1N4007

1000V

D19

1A

1N4007

1000V

D20

2.67K

R25

D25

J1

3

68.1K

R27

100K

R56

500

Q8

2N4401

50V

.022

C21

50V

.022

C24

CR5

500

6.81K

R37

2N5657

Q4

J1

6

SOURCE

POWER

OUTPUT

J2

3

515

500

515

C

D

D

689

OHMS

470

N.B.

PC BOARD

PROCEDURE

INITIATE

CRATER TIME

584C

A

CR6

E

N.F.

-4

CR3

LT1

R

HOT

ELECTRODE

ENABLE

HOLD-LOW

N.D.

530

7.68K

R41

1A

1N4004

400V

D23

100K

R62

Q13

2N4403

22.1K

R42

LED 7K

515

515

515

500

515

500

500

500

100

R17

J3

3

D32

LED 7C

START

D27

581A

J2

4

J2

5

475

R19

D15

22.1K

R18

D8

D9

1.00K

R5

22.1K

R24

4.7

35V

C5

1.50K

R11

D10

J3

2

D16

D13

2974

515

515

500

515

500500

515

500

515

515

LED 7B

DISABLE

687

BURNBACK

TIME OVER

SHUT DOWN

566

565

WELD TIME

OVER

PROCEDURE PC BOARD

528

CURRENT

CR4

STOP

S6

B

A

582

15.0K

R29

N.A.

581

J5

2

LED 7D

D28

D14

1.50K

R13

100

R12

10

25V

C7

475

R4

J2

1

100

R6

1.50K

R3

C6

D12

D11

1.00K

R2

D29

475

R14

J5

1

S5

START

G

N.F. SCHEMATIC SHOWN WITH DIP SWITCHES IN THE "UP" POSITION.

1A

1N4007

1000V

D18

X5

89

50V

.022

C27

10.0K

R40

Q11

2N4401

X5

2

1

C31

CIRCUITRY OF CONTROLS HAVING A COMMON CODE NUMBER.

J4

1

J5

6

X2

10

8

9

C32

BYPASS KIT (ALSO SEE SCHEMATIC A)

7.68K

R53

X1

5

6

4

X1

10

8

9

100K

R55

Q18

2N4403

Q12

2N4403

X1

2

1

3

Q9

2N4401

100K

R54

PER CHARTS BELOW

68.1K

R22

50V

.022

C19

J1

4

J1

1

2N5657

Q2

LED 7H

J4

2

J3

8

50V

.022

C25

N.C. DIP SWITCHES ARE TO BE SET TO SUIT APPLICATION

100K

R63

N.B. COMPONENTS INCLUDED WITH OPTIONAL LINC-FILL

2.67K

R20

515

500

515

500

515

500

1A

1N4004

400V

D22

A

A

N.F.

-1

560

PC BOARD

PROCEDURE

ENABLE

MONITOR

PRESET

CR2

564

PROCEDURE

PC BOARD

TRAVEL

589

PROCEDURE

ENABLE

WELD

610

CYCLE

N.A. SWITCH (SEE PROCEDURE P.C. BOARD SCHEMATIC)

NOTES:

DIAGRAM MAY NOT SHOW THE EXACT COMPONENTS OR

N.E. SINCE COMPONENTS OR CIRCUITRY ON A PRINTED

CIRCUIT BOARD MAY CHANGE WITHOUT AFFECTING THE

INTERCHANGEABILITY OF A COMPLETE BOARD, THIS

IS USED WITH LATER VOLTAGE BOARDS.

EARLIER VOLTAGE BOARDS. ARC CONTROL ENABLE

N.D. HOLD-LOW DISABLE IS USED WITH G1556-1 AND

MUST BE IN "STRIKE" POSITION TO START WELD

500

500

X3

4

5

6

S2

6

12

11

5

X3

12

13

11

D5

J2

2

D6

D2

D1

B1

(HS)

IN

7815

OUT

GND

X9

J4

6

J4

3

X8

7

14

100V

.22

C1

C30

500

T1C BLU

X3

8

9

10

515

4.7

35V

C13

B2

LED 7A

D7

D3

D4

500

50V

C12

515

N.F.

B

C

D

-3

C

A

C

SUPPLY

POWER

LOGIC

628

BLU

22VAC

1.50K

R1

4011

X7

14

7

PROCEDURE

PC BOARD

515

X7

8

9

10

S1

2

16

15

1

500

S1

4

14

13

3

475

R9

475

R10

50V

.022

C11

10

25V

C8

X6

2

1

S1

8

10

9

7

X7

12

13

11

22.1K

R52

X5

4

3

22.1K

R51

X1

11

12

13

J4

4

500

N.F. N.F.

-2

-1

-3

-4

N.F.

N.F.

A

D

PC BOARD

PROCEDURE

588

D

INITIATE

START

TIME

584S

CURRENT

C

PC BOARD

PROCEDURE

D

B

OVER

START TIME

OVER

WELD TIME

C

B

583S

THIS SHEET CONTAINS PROPRIETARY INFORMATION OWNED BY

Ch'ge.Sht.No.

ELECTRICAL SYMBOLS PER E1537

UNLESS OTHERWISE SPECIFIED)

GENERAL INFORMATION

MFD

NONE

SUBJECT

CLEVELAND, OHIO U.S.A.

ON 3 PLACE DECIMALS IS + .OO2

SCALE

RESISTORS = Ohms (

(

UNLESS OTHERWISE SPECIFIED)

CAPACITORS =

.022/50V

DIODES =

1A, 400V

(UNLESS OTHERWISE SPECIFIED)

1/4W

FILENAME: G2974_2DA

MAB

9-27-94

SHT.

LOGIC CIRCUIT

DATE

WITH PUBLISHED STANDARDS

G

ON ALL ANGLES IS + .5 OF A DEGREE

DR.

MATERIAL TOLERANCE ("t") TO AGREE

NA-5

NO.

CHK.

SUP'S'D'G.

2974

THE LINCOLN ELECTRIC CO.

TYPE

THE LINCOLN ELECTRIC CO.

THE LINCOLN ELECTRIC CO.

EQUIP.

LOGIC POWER SUPPLY DISTRIBUTION AND BYPASSING

J4

5

50V

.022

C22

Q6

2N4401

J5

3

50V

.022

C10

100K

R59

22.1K

R31

UNLESS OTHERWISE SPECIFIED TOLERANCE

ON 2 PLACE DECIMALS IS + .O2

ON HOLES SIZES PER E-2056

500

ENABLE

FEED

S3

INCH

UP

586

500

J1

2

18

63

37

X-

R-

7K

9

Q-

LED-

2

35

S-

5

1

B-

J-

2

DZ1-

2

68.1K

R30

LED 7G

1A

1N4007

1000V

D21

100K

R61

2N5657

Q5

1A

1N4004

400V

D24

50V

.022

C20

J1

5

500

500

PCB

PROCEDURE

CR1

585

AND IS NOT TO BE REPRODUCED, DISCLOSED OR USED WITHOUT THE EXPRESS PERMISSION OF

EARTH GROUND CONNECTION

POWER SUPPLY SOURCE POINT

FRAME CONNECTION

COMMON CONNECTION

SUPPLY

VOLTAGE NET

X7

2

1

3

2N5657

Q3

S2

2

16

15

1

D-

LABELS

LAST NO. USED

X7

5

6

4

100K

R60

C-

METHODS OF TRAVEL & BURNBACK.

NA-5 SHIPPED CONNECTED FOR INDICATED

2

SWITCH #1

2

1

3

SWITCH #1

2

1

3

1

3

SWITCH #1

3

Yes

2

2

3

1

SWITCH #1

SWITCH #1

4

4

SWITCH #2

3

1

2 4

3

1

2

current

Start/stop with weld

Start/stop with switches

Methods of Travel

3

1

2 4

3

1

2

SWITCH #2

3

2

SWITCH #1

1

3

WATER

OR

FLUX

No

contactor delay

Wire feed stop with

delay

Inch up with contactor

SWITCH #1

2

receptacle)

Start with start switch

Stop after burn-back time

(Optional procedure

module installed in crater

SWITCH #1

SWITCH #1

1

3

1

(Optional procedure

Start with start switch

module installed in crater

Stop after crater time

receptacle)

Start with weld current

Stop with stop switch

1

637

2

1

3

4

SWITCH #2

44

SWITCH #2

2

Optional Crater Module Installed?

2

1

3

4

SWITCH #2

4

SWITCH #2

500

515 515

1-12-96D

G-4

NOTE: Lincoln Electric assumes no responsibility for liablilities resulting from board level troubleshooting. PC Board repairs will invalidate your factory warranty. Individual Printed Circuit Board Components are not available from Lincoln Electric. This information is provided

for reference only. Lincoln Electric discourages board level troubleshooting and repair since it may compromise the quality of the design and may result in danger to the Machine Operator or Technician. Improper PC board repairs could result in damage to the machine.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC