PRECISION TIG 185

TROUBLESHOOTING & REPAIR

F-11 F-11

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING GUIDE Observe Safety Guidelines

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

1-888-935-3877.

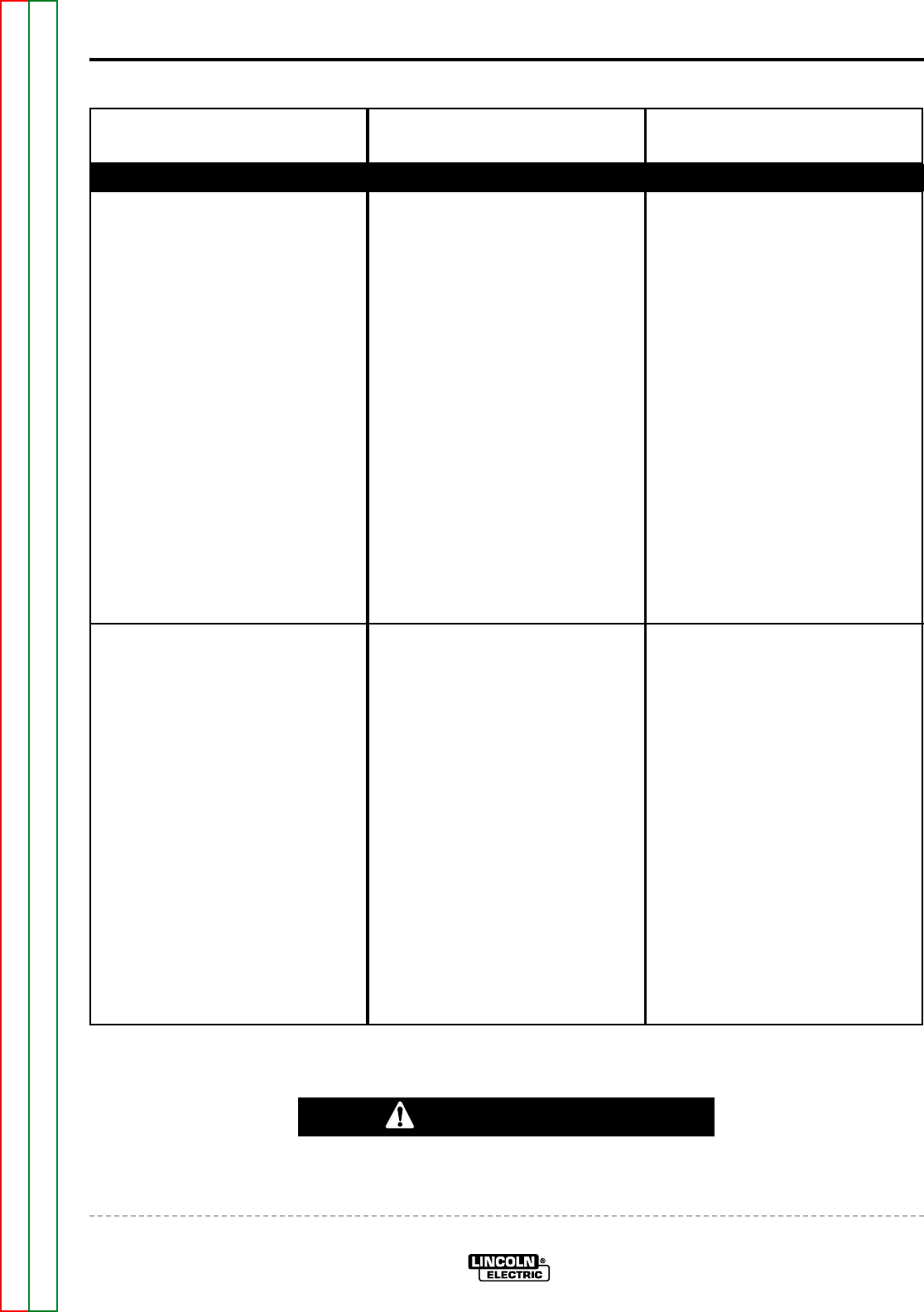

TIG WELDING PROBLEMS

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

High frequency "spark" is present at

tungsten electrode, but operator is

unable to establish a welding arc.

Machine has normal open circuit

voltage. Refer to Technical

Specifications in the Installation

Chapter.

1. The torch may be faulty. Check

or replace.

2. The current control may be set

too low.

3. The tungsten electrode may be

contaminated. Replace or sharp-

en.

4. The electrode may be too large

for the process.

5. If a helium blend is being used

as a shielding gas, then reduce

the percentage of helium.

6. Check the welding cables for

loose or faulty connections.

1. This may be a welding procedure

problem.

Contact The Lincoln Electric Service

Department 1-888-935-3877.