Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

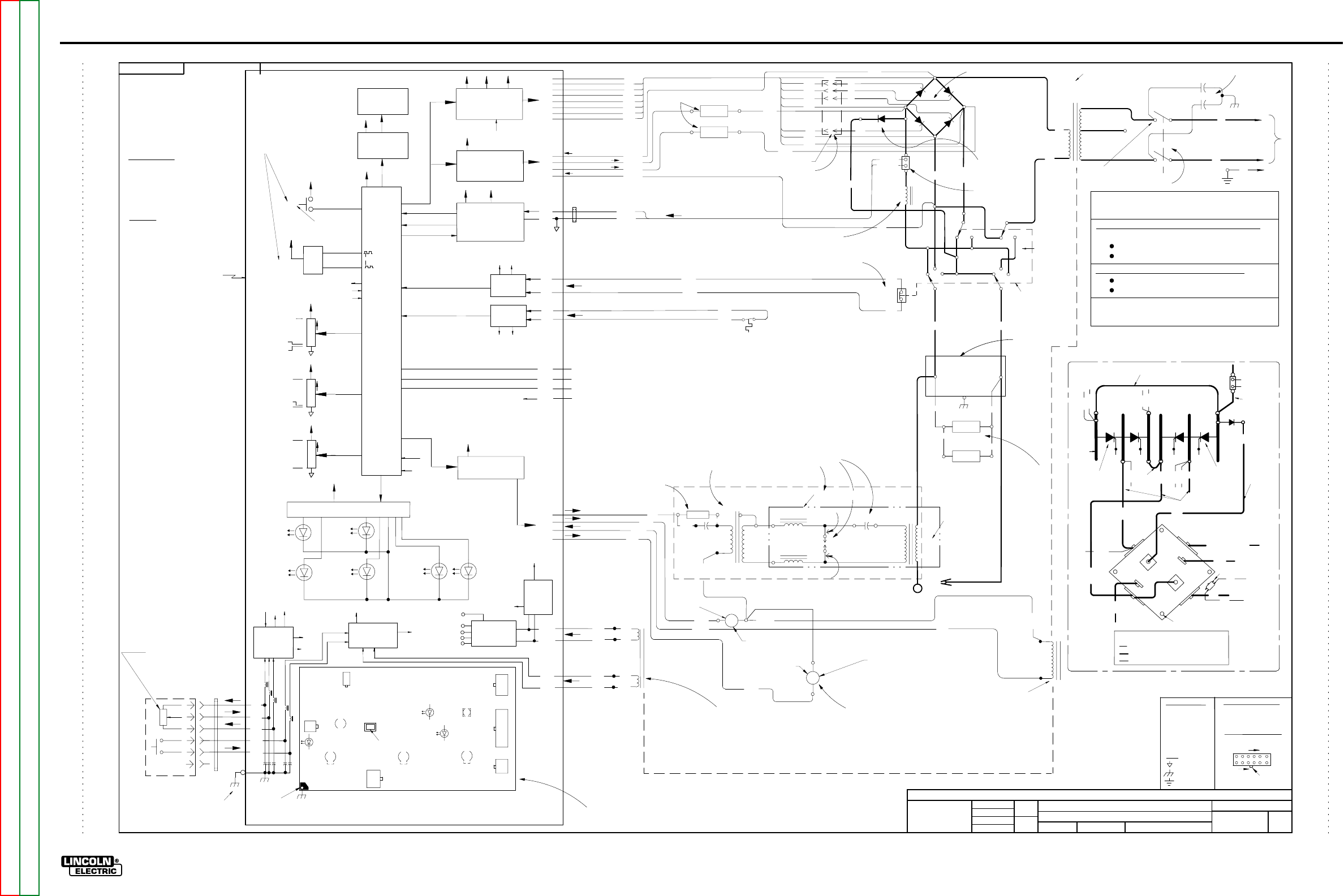

ELECTRICAL DIAGRAMS

G-3

PRECISION TIG 185

SCHEMATIC - ENTIRE MACHINE - (G4588)

EN-170

S

O

L

ID

E

D

G

E

ENGINEERING CONTROLLED

MANUFACTURER:

No

RELEASED FROM X A.02

G4588

Precision Tig 185

MACHINE SCHEMATIC

NONE

Reference

Jbarto

TNguyen

Approve

DRAWN BY:

DESIGN INFORMATION

ENGINEER:

APPROVED:

REFERENCE:

EQUIPMENT TYPE:

SUBJECT:

SCALE:

MATERIAL

DISPOSITION:

APPROVAL

DATE:

PROJECT

NUMBER:

UF

CRM36191

1

PAGE ___ OF ___

1

DOCUMENT

NUMBER:

DOCUMENT

REVISION:

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED

TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC.

PROPRIETARY & CONFIDENTIAL:

A

THE INFORMATION ON THIS

PRINT IS FOR REFERENCE

ONLY. COMPONENTS AND

CIRCUITRY MAY BE

DIFFERENT

FROM AN ACTUAL MACHINE.

02/20/2004

CHANGE DETAIL:

G4588

LEAD COLOR CODE:

B-BLACK OR GRAY

G-GREEN

O-ORANGE

R-RED OR PINK

U-BLUE

W-WHITE

Y-YELLOW

COMPONENT VALUE UNITS:

CAPACITOR: MFD/VOLTS

RESISTOR: OHMS/WATTS

CONNECTOR PIN NUMBERS:

VIEW OF CONNECTOR ON PC BOARD

1

2

6

712

LATCH

EX. 12 PIN CONNECTOR

LABELS:

COMMON

FRAME GROUND

EARTH GROUND

SCR4

SCR3

SCR1

SCR2

MAIN SCR

RECTIFIER

D1

OUTPUT

INDUCTOR

AC

DC

DC

DC

DC

AC

AC

AC

++

-

-

POLARITY SWITCH

SHUNT

MAIN

TRANSFORMER

X1

X2

H1

H2

H3

L2

L1

+

-

250VAC

.0047/

400A/200mV

S2

C1

C2

L1

DC

+

DC

-

DC

+

DC

-

G1

G2

G3

G4

218

217

216

220

SCR3,SCR2 CATHODE

SCR1 CATHODE

SCR4 CATHODE

SCR1,SCR4 ANODE

SCR1 GATE

SCR2 GATE

SCR3 GATE

SCR4 GATE

216A

G4

G3

G2

G1

220

217

218

FREE WHEELING DIODE

POWER SWITCH

R 222(-)

W 221(+)

W 221

R 222

SHUNT (+)

SHUNT (-)

1J1

2J1

TOROID

LOW

HIGH

T1

BYPASS ASSEMBLY

R1

WORK

SV1

GAS

SOLENOID

FAN

X7

X8

HIGH FREQ.

TRANSFORMER

100/100

T2

S

F

C3

.0015/

12KV

SPARK

GAP .020

R3

200/100

C4

15/250

HIGH

VOLTAGE

TRANSFORMER

L2

L3

T3

ELECTRODE

HOLDING RESISTORS

231

231

231A

232

236B

237

238

239

236

HI-FREQ (115VAC)

GAS (115VAC)

FAN (115VAC)

235

260

314

313

THERMOSTAT INPUT

235

232

260

232

115VAC IN

4J4

1J4

2J4

3J4

X5

X6

X3

X4

18VAC

CONTROL BOARD SUPPLY

18VAC

TRIGGER CIRCUIT

209

210

201

204

AUX. WINDINGS OF

MAIN TRANSFORMER T1

CHOKE TSTAT

(SCHEMATIC S22530)

BYPASS/STABILIZER

PCB

115VAC

(115VAC)

115VAC

5.5 OHMS

TYP.

14.5 KOHMS

TYP.

12.5 OHM TYP.

12.5 OHM TYP.

T1

T1

HI-FREQ CIRCUIT

3 DIGIT

METER

CW

R1

CW

10K

RECEPTACLE

TM

OPTIONAL AMPTROL REMOTE

CONTROL AND ARC START SWITCH

A

B

C

D

E

F

U

N

R

B

W

10K

TOROID

C

A

B

OUTPUT CONTROL

(ENCODER)

+5Vref

+5Vref

CW

R2

CW

10K

+5Vref

CW

R3

CW

10K

+5Vref

BALANCE

PULSE FREQUENCY

POSTFLOW

+15V

MODE

STICK

(RED)

TIG

(GREEN)

MICRO-

PROCESSOR

AUT0BALANCE

(GREEN)

FREQUENCY

(GREEN)

THERMAL

(YELLOW)

SEE RATING PLATE FOR SPECIFIC VOLTAGES

230 o

r 400-415 or 575 VOLT CONNECTION

H1 and H3 (HIGH) TO POWER SWITCH.

208 o

r 380 or 460 VOLT CONNECTION

H1 and H2 (LOW) TO POWER SWITCH.

H3 NOT CONNECTED; INSULATE.

H2 NOT CONNECTED; INSULATE.

C1 AND C2 MUST ALWAYS BE CONNECTED

ACROSS TRANSFORMER PRIMARIES

VOLTAGE RECONNECTION

(AS SHOWN & AS SHIPPED FROM FACTORY)

R2

CLOSED

IN DC

311

312

311

312

MICRO SWITCH INPUT

5J3

6J3

N.C.

R5

12/100 EACH

R4

220A

218A

ARC STARTER ASSEMBLY

1J3

2J3

7J3

8J3

4J3

3J3

100/100

284A

285A

285B

284B

284

285

MICRO SWITCH CLOSED IN DC

OPEN IN AC

W

B

G

INPUT PLUG

216

BACKGROUND RESISTORS

BACKGROUND AC INPUT

BACKGROUND ( - )

BACKGROUND ( + )

240

11J3

9J3

10J3

12J3

5J2

6J2

3J2

8J2

2J2

1J2

4J2

7J2

1J5

3J5

2J5

5J5

6J5

METER

INTERFACE

LED INTERFACE

J2

J3

J4

J5

J6

J1

+15V

(GREEN)

+5V

(GREEN)

+5Vref

(GREEN)

CONTROL PCB MAIN COMPONENT & DIANOSTIC LED LAYOUT

(VIEWED FROM COMPONENT SIDE)

AUTO LOCAL/REMOTE

STICK MODE: ALWAYS LOCAL

TIG MODE: REMOTE IF PLUGGED

LOCAL IF UNPLUGGED

2 PIN

6 PIN

8 PIN

12 PIN

4 PIN

4 PIN (WHITE)

PROGRAMMING

CONNECTOR

HI-FREQ BYPASS

CONNECTION

SCHEMATIC G4550-

ASSEMBLY G4551-

CONTROL PC BOARD

+5V

30 S

1 S

20 HZ

OFF

MAX. PENETRATION

AUTO

MAX. CLEANING

5 - 185A IN DC

7 - 185A IN AC

+5V

+5Vref

OUTPUT CONTROL &

MODE SETTINGS ARE

MEMORIZED AT POWER

- DOWN AND RECALLED

AT POWER - UP

SCR

GATING & SNUBBER

+15V

+5V

MICRO-START

CIRCUIT

+15V

OUTPUT REGULATOR

+15V

115V CIRCUIT

TRIAC & OPTO-TRIAC

DRIVER

+15V

(PCB AS'BLY L10121-1)

435 OHMS TYP.

12 OHMS TYP.

FAN RUNS FOR 5 S AT POWER-UP

STOPS AT IDLE 8 MINUTES

AFTER WELDING.

COMPONENT LOCATION DESCRIPTIONS ARE AS VIEWED

FROM FRONT OF MACHINE UNLESS STATED

OTHERWISE

G4

G3

G2

G1

IN-LINE CONNECTOR J7

4

3

2

1

In Front of main

transformer,

Attached to Base

Left side of Machine

near front

Rear Panel

Right Side

Right Side of SCR Bridge

Rectifier. Top of Machine

behind Choke.

Right side of Machine

above Choke Coil.

Right side of machine,

front of gas solenoid,

attached to Base

Attached to Power Switch

S1

Front Panel Left side

Front Panel Center

Front Panel Top

Inside hi-freq box on

right side of machine

near front

Rear of machine attached to

base, below fan

0.1 HZ

Right front side of

Main Transformer

Between SCR Bridge halves

behind choke.

Mounted to front side

of hi-freq box on

right side of machine

near front.

Lower left side of

Polarity Switch

Inside hi-freq box on

right side of machine

near front

BACKGROUND AC INPUT

245

244

216A

240

TWISTED PAIRS

BALANCE

POSTFLOW

FREQUENCY

(NORMALLY CLOSED

OPEN AT 135C TYP.)

Right rear side of Main

Transformer

80 VAC

On top of Main

Transformer

Inside sleeving at top left side of

Main Rectifier

DISPLAY PRESET AT IDLE

ACTUAL AMP WHEN WELDING

NO HOLD FUNCTION

(DISABLED IN STICK)

OUTPUT CONTROL

X1

SOFTWARE

VERSION LABEL

65V IN DC

75V IN AC

POWER-UP SEQUENCE

METER AND MODE DISPLAY THE PREVIOUS OUTPUT

CONTROL AND MODE SETTINGS. FAN RUNS FOR 5

SECONDS. IF MODE IS TIG, GAS FLOWS FOR A TIME

SET BY THE POSTFLOW KNOB. OUTPUT IS HOT IF

MODE IS STICK. IN TIG MODE OUTPUT IS COLD UNTIL

TRIGGER IS CLOSED

(DISP1)

A1

S1

METER, ENCODER, SWITCH, LEDs,

AND ALL POTENTIOMETERS ARE

MOUNTED ON PC BOARD

TYPICAL OCV

TOGGLE BETWEEN TIG &

STICK.

HI-FREQ, GAS, BALANCE

CONTROL, PULSE

FREQUENCY, &

MICRO-START CIRCUIT

ARE DISABLED IN STICK

LED 1

LED 3

LED 4

LED 5

LED 2

THERMAL

(YELLOW)

LED 6

NEXT TO MODE SWITCH

NEXT TO BALANCE POT.

NEXT TO PULSE

FREQUENCY POT.

NEXT TO METER

NEXT TO METER

NEXT TO MODE SWITCH

OFF IN STICK AND DC TIG

OFF IN STICK, BLINKS AT

FREQUENCY RATE

TWO THERMAL LEDs TO

LIGHT THROUGH

BACK-LIT THERMAL

SYMBOL

MODE

MICRO-PROCESSOR

1J6

2J6

3J6

4J6

+5Vref

DATA

SCLK

XRES

PROGRAMMING CONNECTOR

FOR SOFTWARE UPGRADE

HI-FREQ BYPASS CONNECTION

FROM BOTTOM LEFT

MOUNTING HOLE TO SHEET

METAL

Left front

SCR4

SCR2

SCR1

SCR3

G4

216

G3

2

1

8

G

2

G

1

2

1

7

A

C

D1

+

( )

( )

_

2

1

6

A

X

2

2

2

0

2

1

8

A

P

O

S

S

H

U

N

T

2

2

0

A

D

C

2

1

6

A

R 222R 222

W 222

TO0 COPPER BAR

BOTTOM

COPPER

BAR

6 GA. FLEX LEADS

7 GA. FLEX LEAD

ALUMINUM BAR

FARTHEST LEFT

SCR (VIEWED

FROM FRONT)

FARTHEST RIGHT SCR

(VIEWED FROM

FRONT)

SCR

HEATSINK

SCR BRIDGE AND POLARITY SWITCH CONNECTION DETAIL

240

P

O

S

DC

285

2

8

4

OUTPUT INDUCTOR

X1

MOUNTING HOLE

Gang D

Gang A

gang B

Gang C

Rear gang G

Rear gang H

Gang F

Gang E

GANG LOCATIONS ARE

VIEWED FROM REAR OF

SWITCH

POLARITY SWITCH

MICRO SWITCH

A-C, D-E, B-F

B-D, C-E, A-F, G-H

B-D, A-E, C-F, G-H

OPEN

CLOSED

CLOSED

AC

DC+

DC-

311

312

MICRO SWITCH

UNUSED TERMINAL

RECONNECT IS DONE AT

POWER SWITCH

Center of machine

Top rear

SEE CONNECTION DETAIL

SETPOINT

PHASE_FIRE

INTERFACE

INTERFACE

AC/DC

THERMOSTAT

DETERMINE IF HI-FREQ IS

CONTINUOUS OR START

ONLY, MIN. CURRENT, AND

BALANCE CONTROL

DISABLE OUTPUT & HI-FREQ

IF THERMOSTAT OPEN

CURRENT FEEDBACK

Iarc

PHASE

DETECTOR

POWER SUPPLY

+15V

+5V

+5Vref

-15V

PHASE

TO MICRO PROCESSOR

AND SCR GATING

PHASE

PHASE

AUTO

LOCAL/

REMOTE

CONTROL

DET_REM

REM_SENSE

REM_POT

TO MICRO

PROCESSSOR

DET_REM

REM_SENSE

REM_POT

From Auto Loc/Rem

Polling signal

Hi = Local

Remote control

TRIGGER

INTERFACE

TRIGGER

TRIGGER

TO MICRO

PROCESSOR

DO NOT REVERSE LEADS

209 & 210, USED FOR SCR

PHASE TIMING

115V

5000V

HI-FREQ OFF IN STICK

START ONLY IN DC TIG

CONTINUOUS IN AC TIG

Right front

Center front

TYP. RPM:

1600 RPM 60Hz

1340 RPM 50Hz

15 - 20 OHM

GATE-CATHODE

RESISTANCE TYP.

FIRE_SCR

BG

-15V

RF

CHOKES

+15V

-15V

+5V

+24V

+5V

+24V

+5Vref

+24V

+5Vref

+24V

DC

AC

P

O

S

Gang D

Gang A

Gang C

Gang G

Gang B

Gang H

Gang E

Gang F

CBW

CBW

CBW

CBW

CBW

CBW

CBW

CBW

CBW = CONNECTED

BY SWITC H

THESE CONNECTIONS

ARE MASE BY POLARITY

SWITCH, THEY ARE NOT

PHYSICAL LEADS

CBW

SEE CONNECTION DETAIL

BALANCE CONTROL IS

DISABLED IN STICK AND

DC TIG

PULSE FREQUENCY IS

DISABLED IN STICK

G-3

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.