TM-353 Page 27Syncrowave 250

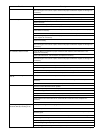

SC-188 161

Test Equipment Needed:

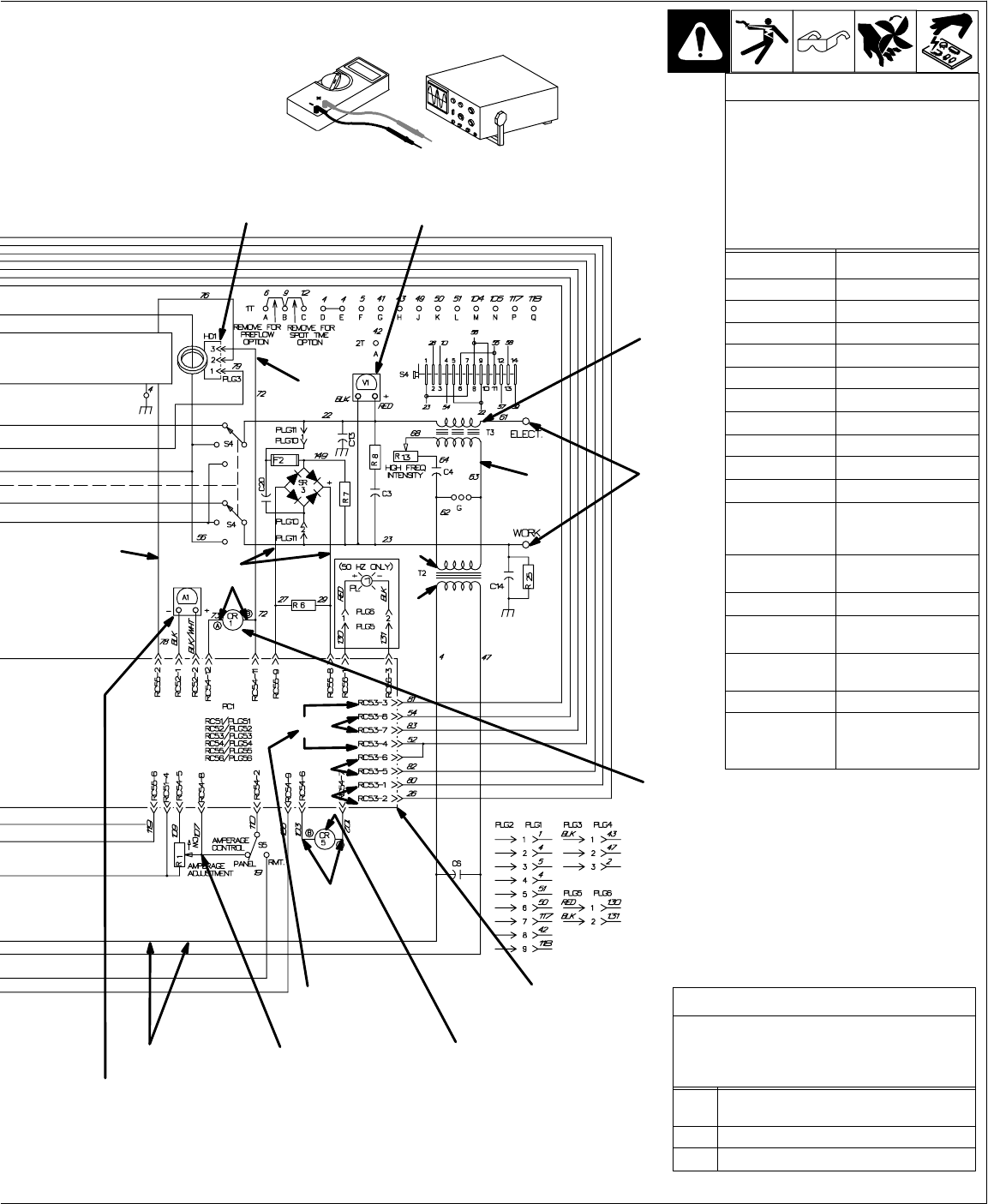

V24

V22

V21

R3

R2

V20

A

A

A

A

R1

V25

Resistance Values

a) Tolerance – ±10% unless specified

b) Turn Off unit and disconnect input

power before checking resistance

R1 All values for T1, Z1, and T3 are less

than 1 ohm

R2 5.3 ohms

R3 6.1 K ohms

Voltage Readings

a) Tolerance – ±10% unless

specified

b) Reference – to circuit

common (lead 42) unless

noted

c) Wiring Diagram – see

Section 10

V1 230 volts ac

V2 77 volts ac

V3 82.5 volts ac

V4 57 volts ac

V5, V6 115 volts ac

V7 24 volts ac

V8, V9 18 volts ac

V10 10 volts ac

V11 80 volts dc

V12. V13, V14 115 volts ac

V15, V16, V17 24 volts ac

V18 115 volts ac with S2

in Start or Con-

tinuous

V19 0 to +10 volts dc

with contactor on

V20, V21 24 volts dc

V22 0-80 volts dc (rec-

tified arc voltage)

V23 maximum 80 volts

ac/dc

V24 24 volts dc

V25 16.5 millivolts dc

per 1 ampere of

weld output

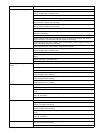

CR1 energizes

when open-circuit voltage

is present; denergizes

when an

arc is struck

See Figure 10-1 for

HD1 location

No calibration available

for voltmeter V1

R1

V23, B,

C, D, E

See Section 6-3

for waveforms

B, C, D, E

See also

Sections 6-4 and 6-5

for PC1 data

CR5 energizes when

contactor is on

See Section 6-8

for ammeter A1

calibration

V19

V18

See Section 6-3

for waveform A