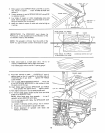

9. Holdrodwithonehandandwitha1/2in. wrench or

pliers start screwing on ONE of the nuts only A TURN

OR TWO .... screw on other nut the same way

10_ Using TWO 1/2 in,, wrenches or pliers tighten both of

the nuts,

IMPORTANT: Apply a coat of paste wax to the top surface

and front edge of the front guide bar, This will allow the

fence to slide more easily,

11o Slide the bars so that screws are in the MIDDLE of the

slotted ho_eso

12. Position rip fence over miter gauge groove, holding up

the rear end while engaging front end with bar o..

lower fence onto table°

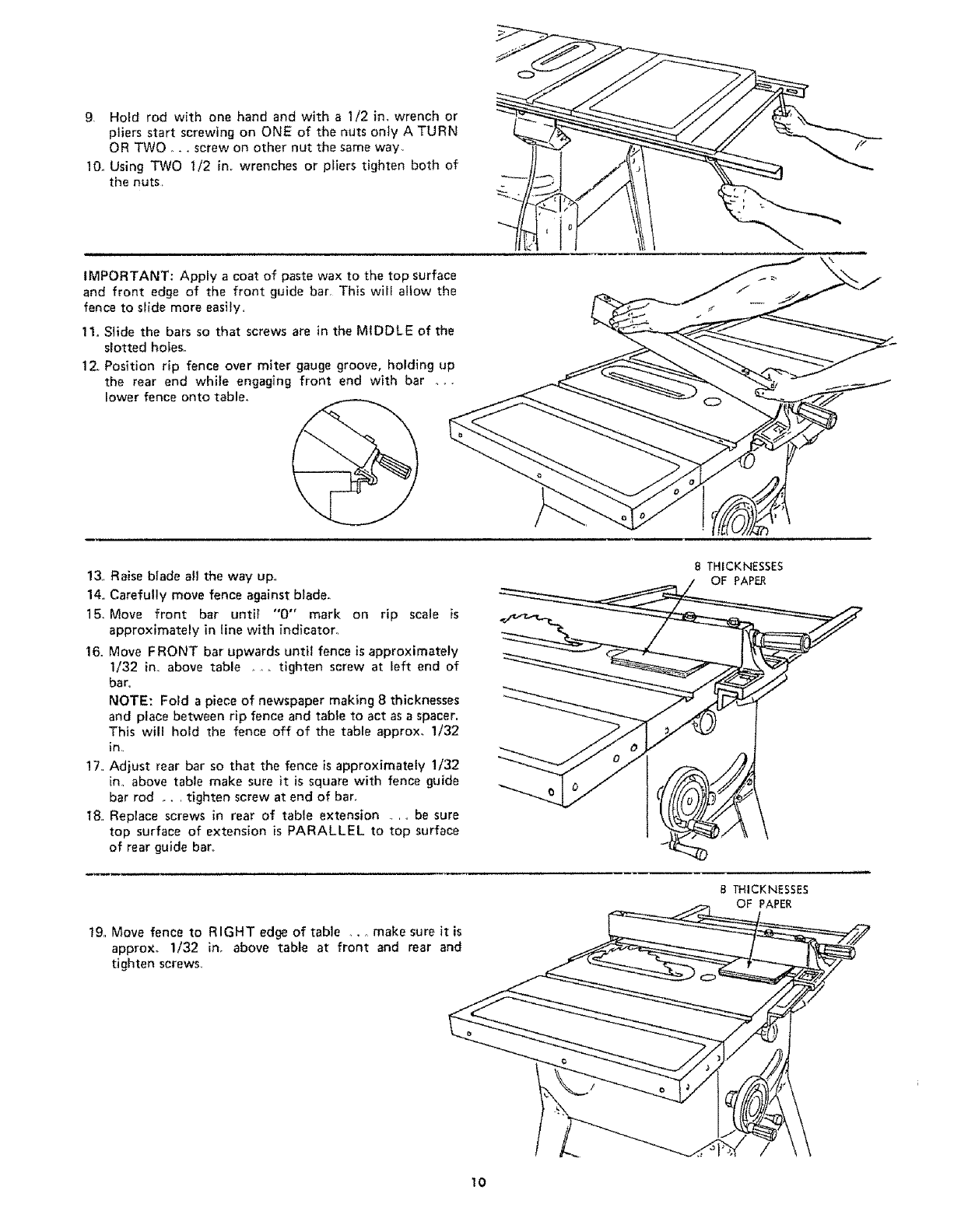

!3,, Raise blade all the way up.

14. Carefully move fence against blade.

15, Move front bar until "0" mark on rip scale is

approximately in line with indicator°

16. Move FRONT bar upwards until fence is approximately

1/32 in,, above table .... tighten screw at left end of

bar_,

NOTE: Fold a piece of newspaper making 8 thicknesses

and place between rip fence and table to act as a spacer.

This will hold the fence off of the table approx. 1/32

in,

17,, Adjust rear bar so that the fence is approximately 1/32

in, above table make sure it is square with fence guide

bar rod .. , tighten screw at end of bar.

18,, Replace screws in rear of table extension .... be sure

top surface of extension is PARALLEL to top surface

of rear guide bar,,

8 THICKNESSES

OF PAPER

19_ Move fence to RIGHT edge of table .... make sure it is

approxo 1/32 in. above table at front and rear and

tighten screws.

8 THICKNESSES

OF PAPER

Io