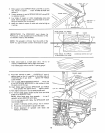

Lay REAR FENCE GUIDE BAR on table to act as a

straightedge. If outer edge of extension is higher or lower

than table surface;

A, Slightly loosen nuts holding bracket to extension

using 7/16 in. wrench,

B, Move end of extension up or down until outer edge

is even with table surface .... check with GUIDE

BAR , ,, tighten nuts.

C Recheck INNER edge of extension to make sure it

has not moved .... readjust, if necessary,

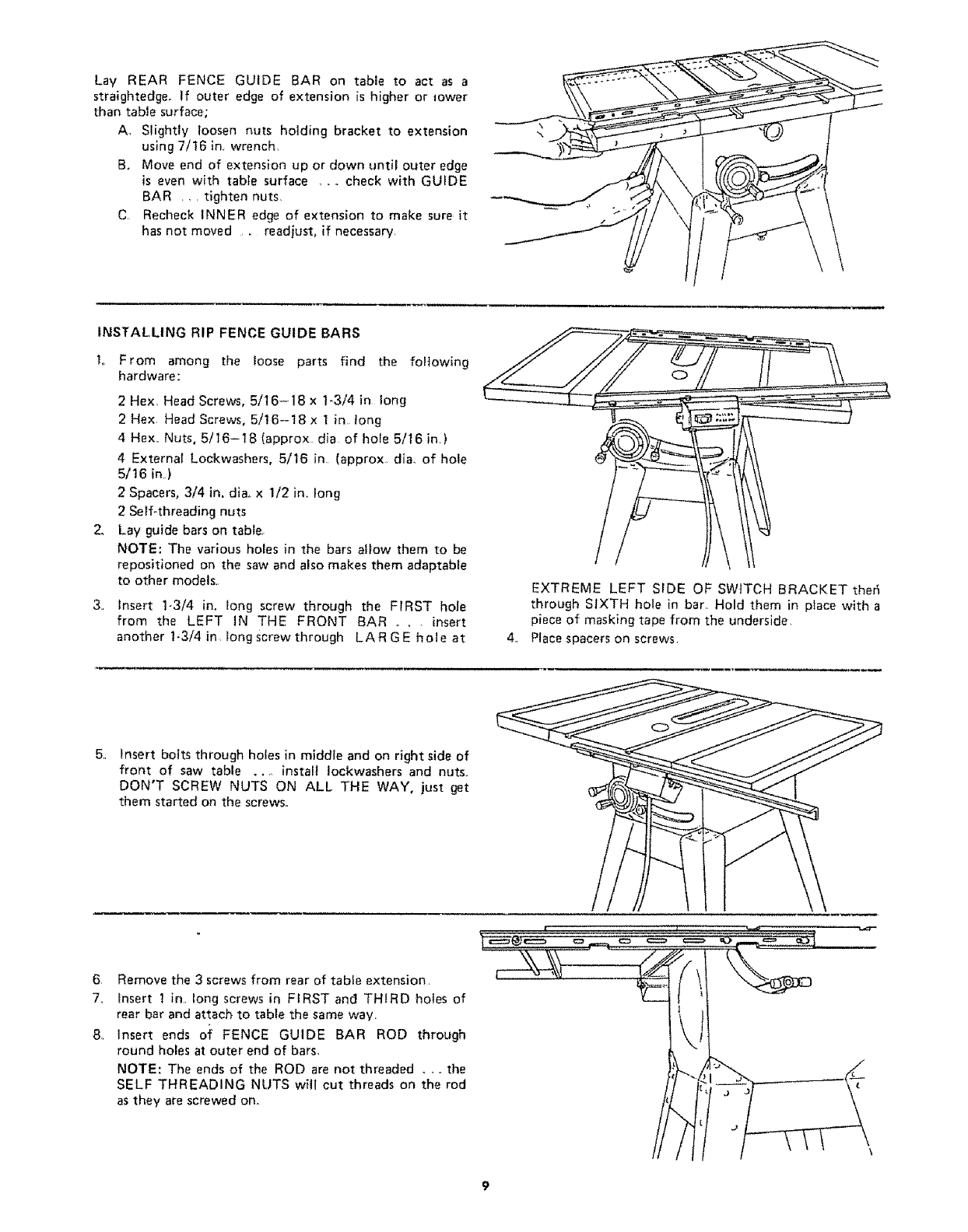

INSTALLING RIP FENCE GUIDE BARS

I,. From among the loose parts find the following

hardware:

2 Hex Head Screws, 5/16-t8 x 1-3/4 in long

2Hex Head Screws, 5!16-18x 1 in long

4 Hex., Nuts, 5/16-18 (approx dia of hole 5/16 in )

4 External Lockwashers, 5/16 in (approx. dia, of hole

5/16 in,)

2 Spacers, 3/4 in. diao x 1/2 in. long

2 Self-threading nuts

2, Lay guide bars on table,

NOTE: The various holes in the bars allow them to be

repositioned on the saw and also makes them adaptable

to other models,

3., Insert 1-3/4 in. long screw through the FIRST hole

from the LEFT IN THE FRONT BAR . _ _ insert

another 1-3/4in long screw through LARGE hole at 4_

EXTREME LEFT SIDE OF SWITCH BRACKETthed

through SIXTH hole in bar Hold them in place with a

piece of masking tape from the underside

Place spacers on screws,

5.

Insert bolts through holes in middle and on right side of

front of saw table ..o install lockwashers and nuts

DON'T SCREW NUTS ON ALL THE WAY, just get

them started on the screws.

6

7.

8,

Remove the 3 screws from rear of table extension.

Insert I in,, long screws in FIRST and THIRD holes of

rear bar and attach to table the same way

Insert ends of FENCE GUIDE BAR ROD through

round holes at outer end of bars.

NOTE: The ends of the ROD are not threaded ... the

SELF THREADING NUTS will cut threads on the rod

as they are screwed om

[ ====e_e=:=